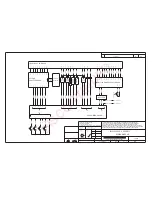

ORANGE WIRE

BROWN WIRE

BLACK WIRE

RED WIRE

BLUE WIRE

YELLOW WIRE

WHITE WIRE

BLACK WIRE

GREEN WIRE

YELLOW WIRE

BLUE WIRE

RED WIRE

GREEN WIRE

WHITE WIRE

BLACK WIRE

RED WIRE

BLACK WIRE

BROWN WIRE

RED WIRE

ORANGE WIRE

YELLOW WIRE

GREEN WIRE

BLUE WIRE

PURPLE WIRE

GREY WIRE

WHITE WIRE

PINK WIRE

GREEN/YELLOW WIRE

BLUE WIRE

BROWN WIRE

J2 OF CPU BOARD

(ITEM 58,SECTION

VIEW A-A, SHEET 2)

BLACK WIRE

BROWN

RED WIRE

ORANGE WIRE

YELLOW WIRE

GREEN WIRE

BLUE WIRE

PURPLE WIRE

GREY WIRE

WHITE WIRE

PINK WIRE

UNTINNED

SOLDER TO POWER SUPPLY BOARD AS

SHOWN ON SECTION VIEW C-C, SHEET 2

12.00

7X 2.75

6X .25

.25

1.00

6X .25

7X 1.25

.25

1.00

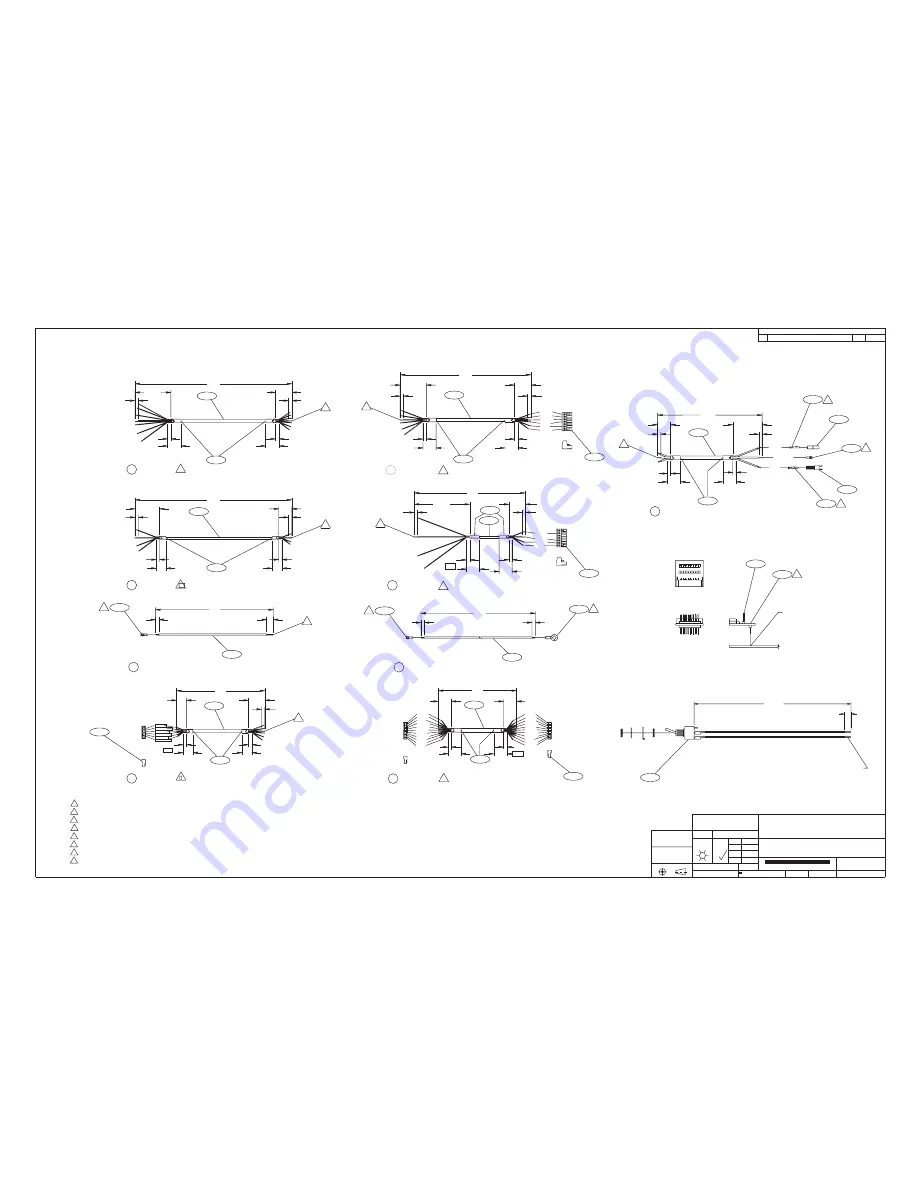

A

CABLE ASSEMBLY

12.00

CABLE ASSEMBLY

B

4X 1.88

4X .25

.25

.75

4X 1.00

4X .25

.25

.75

9.00

WIRE ASSEMBLY

C

.25

.50

6.75

6X .75

CABLE ASSEMBLY

D

.25

.75

.25

.75

10.00

CABLE ASSEMBLY

E

6X 2.00

.25

6X .25

6X 1.25

.25

F

CABLE ASSEMBLY

8.50

4X 4.25

4X .25

.25

1.00

4X 1.25

4X .25

1.00

.25

18.25

G

WIRE ASSEMBLY

.25

.25

H

CABLE ASSEMBLY

11X 1.00

6.00

1.00

.25

11X 1.00

1.00

.25

8.00

3X 1.00

1.00

.25

CABLE ASSEMBLY

.25

1.00

J

3X .25

3X 2.25

3X .25

BARE BOARD ASSEMBLY

SCALE: 2X

NOTES:

1. WIRE END TINNED.

2. CRIMP ON NON-TINNED WIRE END.

3. SOLDER TO CPU BOARD.

6. REMOVE SHIELD WIRES FROM BOTH ENDS.

4. REMOVE BROWN, ORANGE, PURPLE, GREY, WHITE, AND PINK WIRES FROM BOTH ENDS.

5. REMOVE BROWN, ORANGE, PURPLE, GREY, WHITE, PINK, AND SHIELD WIRES FROM BOTH ENDS.

7. REMOVE TAN, PURPLE, GREY, GREEN, WHITE, PINK, AND SHIELD WIRES FROM BOTH ENDS.

8. REMOVE TAN AND SHIELD WIRES FROM BOTH ENDS.

SETUP SWITCH ASSEMBLY

SCALE: 2X

2X 6.00

2X .25

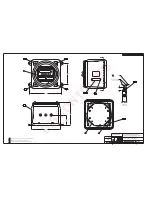

REVISIONS

REV

REFERENCE

INIT

DATE

DRAWING TOLERANCES

UNLESS OTHERWISE SPECIFIED

DO NOT SCALE

DRAWING

RICE LAKE WEIGHING SYSTEMS

IQ+310A XPCD, ASSEMBLY

19212

1:2

3

4

±

.13

±

.060

---

---

SEE BILL OF

MATERIAL

SEE NOTES

NEW

DFH 5/22/02

SCALE

TREATMENT

ANGLE

3 PLC

2 PLC

TOL.

DECIMAL

TITLE

SHEET OF

DWG NO

REVISION

SURFACE

FINISH

MATERIAL

THIRD ANGLE PROJECTION

FOR RLWS

USE ONLY

MFG.ENG.

DR.BY

APPROVED

DES.ENG.

APPROVED

CKD.

0

(30)

55

54

29

50

49

47

51

32

47

32

47

70

70

48

46

78

29

38

31/2X

32

47

46

48

29

38

47

32

52

7

(33)

1

3X

12X

1

8X

1

12X

1

8X

1

1

1

6X

2

2

2

2

2

3

4

5

6

6

7

8

2

THIS DRAWING AND ALL INFORMATION CONTAINED HEREIN IS AND REMAINS

THE PROPERTY OF RICE LAKE WEIGHING SYSTEMS INC. AND IS CONFIDENTIAL.

IT IS SUBMITTED AND MAY BE USED ONLY IN CONNECTION WITH RICE LAKE

WEIGHING SYSTEMS' PROPOSAL AND/OR ITS CUSTOMERS' ORDERS. IT SHALL NOT BE

DISCLOSED TO OTHERS OR COPIED WITHOUT RICE LAKE WEIGHING SYSTEMS' SPECIFIC

WRITTEN CONSENT AND SHALL BE IMMEDIATELY RETURNED UPON REQUEST.

UNLESS OTHERWISE SPECIFIED

ALL THREADS TO BE CLASS 2

ALL DIMENSIONS APPLICABLE AFTER TREATMENT

UNITS TO BE INCHES

DISCONTINUED