Trimming and Calibration

11

3. The lowest reading of the four is the reference

cell. Do not change that cell’s signal. Instead

use the individual cell potentiometers for the

other three cells to reduce those signals to

match your reference cell. Remember that you

turned all pots to full signal before starting, so

you can not increase the signal from any cell

— only decrease signal by trimming with the

pots.

4. Note that the best trim is always the least trim.

If one of the four readings differs from the

others by more than 5% of the displayed

counts, there is probably a mechanical

problem with that load cell mount causing the

large difference. Find it and correct it before

going on. Check for binding, an out-of-level

or misaligned link, or similar problems with

the load cell and mount.

Do not

try to trim

down large signal differences with resistance

pots — that only adds larger problems later

because of interaction between mounts.

5. Park the loaded weight cart over one of the

high-reading cells on side 1. Turn that cell’s

individual potentiometer until the displayed

reading equals your recorded reference cell

reading. Repeat for the other two high-reading

cells on side 1.

6. As adjustments are somewhat interactive,

repeat the process in steps 1 – 5 until all four

cells on side 1 read within .1% of each other.

7. Repeat steps 1 – 6 for load cells 5 – 8 on side

2 of the scale.

4.3

Trimming Paired Sections

Now that all individual load cells are trimmed for

equal output, pairs of load cells on opposite sides of

the scale must be trimmed for equal sectional output.

This process is called

section trimming

.

1. Park the loaded weight cart in the middle of

the scale and directly over an imaginary line

connecting an end pair of cells (1 and 8 in

Figure 4-4). Record the indicator reading.

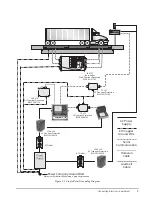

Figure 4-4. Trimming Paired Section 1:8

Move the weight cart directly over the next paired cell

section (2, 7 in Figure 4-5) and record the indicator

reading. Do the same for the last two paired sections

(cells 3, 6 and 4, 5)

.

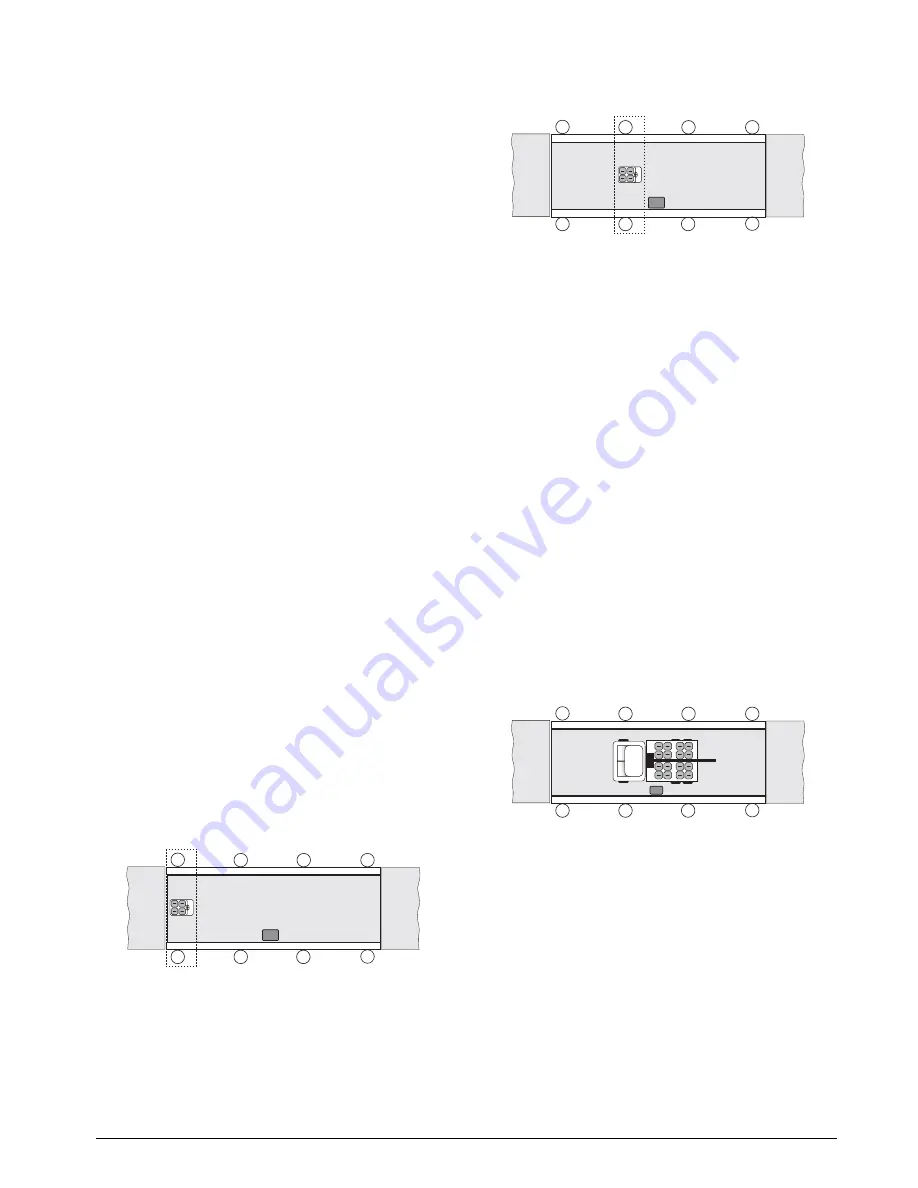

Figure 4-5. Trimming Paired Sections 2:7, 3:6, and 4:5

2. Choose the lowest reading of the four as your

reference section, which is not adjusted.

Using the

section

potentiometers, reload the

other three sections in turn and trim the

sections to match the reading of the reference

section. Recheck section readings a second

time as the adjustment made can be somewhat

interactive.

3. As a final verification of the load cell

trimming, do a final corner check. Place a

1000 lb weight on one corner of the platform

and record the raw-count reading on the

indicator. Move the weight to all of the other

corners in turn and record those readings. The

readings should be within .1% of each other.

4.4

Calibrating with Test Weights

The calibration procedure can only be done after all

trimming as described above has been completed. A

qualified scale technician with a test weight truck and

the expertise to access the scale indicator’s setup or

calibration mode must perform the calibration

procedure.

Figure 4-6. Calibration with Test Weights

1

4

3

2

8

5

6

7

1

4

3

2

8

5

6

7

1

4

3

2

8

5

6

7

Summary of Contents for SURVIVOR ATV series

Page 1: ...ATV Portable Truck Scale Assembly Instructions 68982...

Page 2: ......

Page 4: ...ii ATV Portable Truck Scale Assembly Instructions...

Page 20: ...16 Assembly and Foundation Drawings Figure 7 2 ATV Single Module 30 Assembly Drawing...

Page 21: ...ATV Portable Truck Scale Assembly Instructions 17 Figure 7 3 70 x 11 ATV Pier Foundation Print...

Page 22: ...18 Assembly and Foundation Drawings Figure 7 4 30 ATV Pier Foundation Print...