Recheck Link for Binding

© Rice Lake Weighing Systems

●

All Rights Reserved

19

6.2 Pour and Finish Concrete Deck

1. Mix the concrete no wetter than a standard 3'' slump. The strength of concrete is largely dependent on the

water/cement ratio.

Adding extra water to make the concrete easier to pour and work with reduces the strength and increases the size

and number of shrinkage cracks.

To increase flow, use an electric concrete vibrator rather than adding extra water to the mix.

2. Begin pouring at one of the end modules, thoroughly vibrating works the concrete into the inside of the main beams

and around the shear connectors.

Figure 6-2. Junction Box Pocket

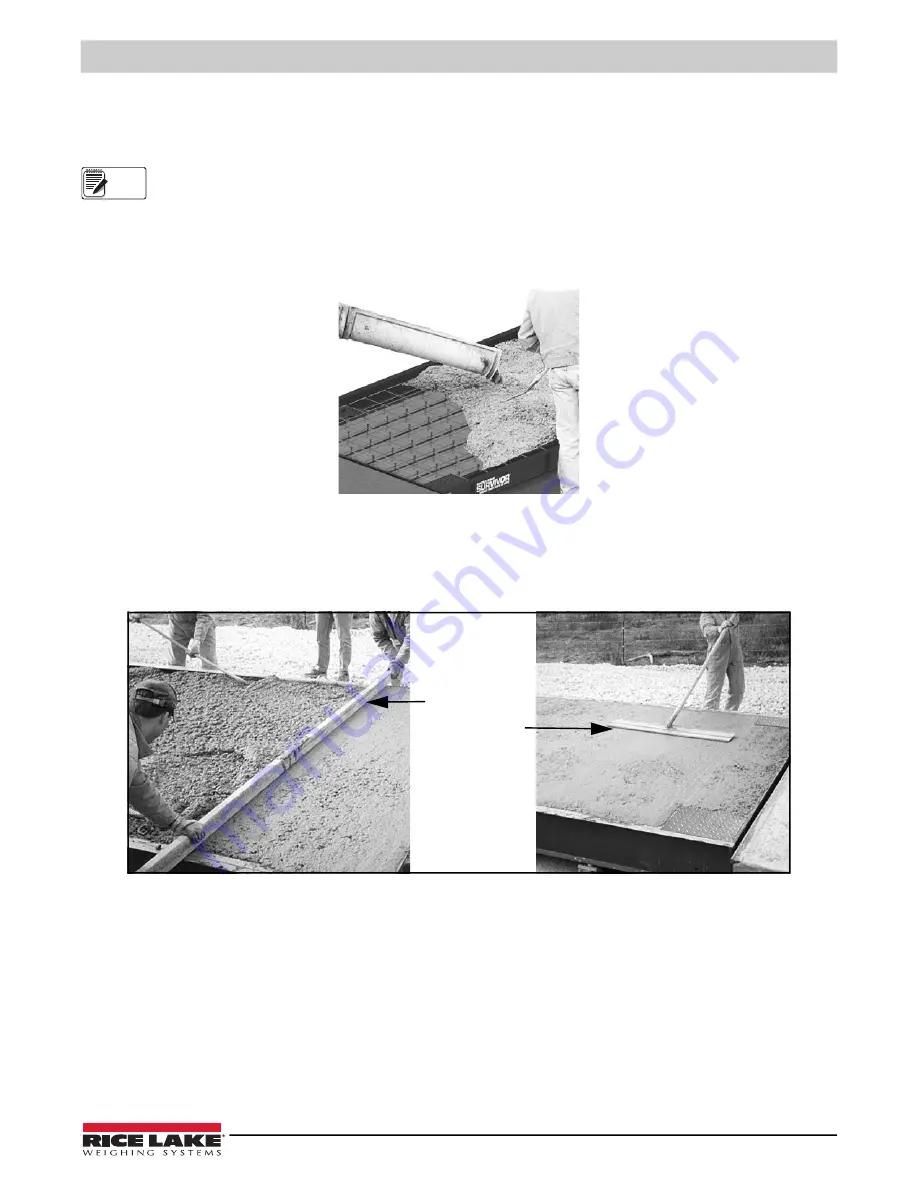

3. Strike off and screed the concrete to further settle the concrete and level the surface.

4. The first module can be bull floated to final level while the second module is being poured. Edge all concrete/metal

frame joints.

Figure 6-3. Junction Box Pocket

5. Pour, screed, float, and edge any remaining modules. After the concrete deck surface has hardened, brush with a

broom to provide safe traction.

6. Clean concrete splatters from the painted frame members with a wet sponge before they dry, and before applying a

liquid curing agent.

7. Apply liquid curing agent to complete concrete pour and finish (

).

Note

Screed Concrete

Float Concrete