Pour and Finish Concrete Deck

9

4.0 Pour and Finish Concrete Deck

With a concrete crew of three experienced workers, a 70' by 10' scale can be

poured and finished in approximately three hours. Access to only one side of

the scale is necessary as most concrete trucks carry extension chutes at least

16' long. If possible, order concrete in front-unloading trucks. The truck will

be moving slowly while filling; the improved driver-visibility with

front-unloading makes that process faster and more accurate.

To protect against unsightly concrete splatters on the top of the support

channels, mask off the top of the channel with tape or use 4 to 6 mil plastic to

cover the top surface.

Position the unloading chute at the near left side of the scale and begin filling

having the truck move slowly to the right.

To ensure concrete flowing evenly into the frame and encasing all Nelson studs and

rebar, a concrete vibrator is highly recommended. These units are available for rent

at most construction equipment rental sources. They work very quickly to level

concrete, settle out surface stones, and leave a stone-free layer at the top surface to

make finishing easier.

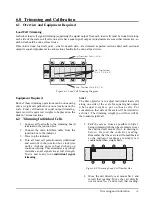

After vibrating to approximate level, screed the concrete to the level of the top

of the support channels with a 2x4 board cut to length

With the deck level and floated, finish with either a magnesium float or steel

trowel for a neat deck line level with the top of the support beams and top of

the pit.

When the entire frame has been floated with a magnesium float and has set

enough for finishing, use a radius edger to finish the metal/concrete joint.

For a non-skid surface, use a stiff bristle broom for a brushed finish when

the concrete has set enough for final finishing. It is recommended that a

non-skid surface be applied for all northern tier states.