10

Survivor

®

PT Pit-Type Truck Scale

Assembly Instructions

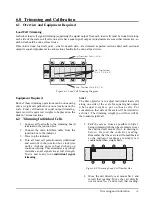

Curing the Completed Concrete Deck

The concrete deck must be maintained in a moist state for at least seven days for a satisfactory cure. If the top

surface of the deck is allowed to dry during this time, the finished surface will be prone to unsightly spalling and

be weakened from surface cracking.

A moist surface can be maintained by covering the entire deck with a continuous 4 to 6 mil sheet of polyethylene

plastic turned up and dammed at the ends and kept filled with 1" of water. Alternately, an epoxy-based concrete

curing solution can be sprayed or rolled onto the deck surface immediately after final finishing and while the

concrete surface is still moist. As the epoxy curing solution will also seal in concrete stains on the exposed

support beams, clean off stains with a damp sponge before applying the curing solution to the deck. Epoxy-based

concrete curing products are available at contractor-supply companies. Do not use the petroleum-based or

paraffin-based waterproofing agents specifically advertised for wood decks and concrete patios. These products

are not curing agents, and will allow the deck surface to rapidly dry.

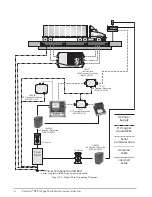

4.1 Optional Equipment

The following is a brief summary of the optional Survivor SR-PT equipment available from RLWS.

Eighteen Inch Main Beam Module

An 18" main beam module is available from RLWS as an option. Use of this option will require increasing the pit

pillar height approximately 6". Refer to the appropriate drawing for exact pit dimensions. This option should

only be used in states where there is a requirement for a minimum of 48" clearance below the main I-beam

flange. (Steel weight is increased approximately 1/3 when selecting this option.)