RP-II-CS8G [C]

18

Sheet 8 of 16

www.richards-mfg.com

Product Family

CS8

9

.4

Mounting CS8

A. Hand-tighten stud into the appropriate mating part or bushing.

!

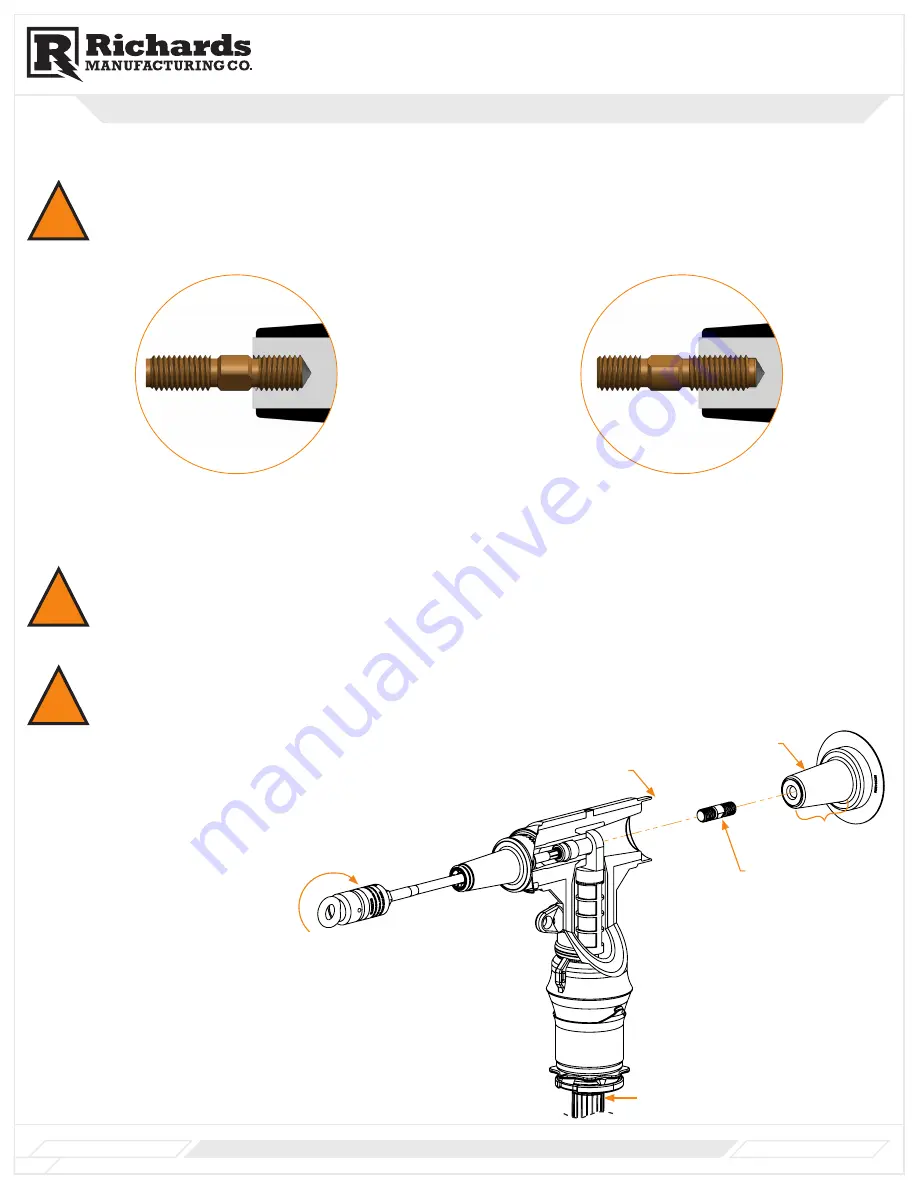

WARNING: A standard threaded stud is included in the kit. If the use of an asymmetrical threaded stud is approved, it MUST be installed

with longer threaded side facing AWAY from equipment as shown below.

Correct

Incorrect

✘

B. Clean and lubricate (using supplied or approved silicone grease) deadbreak interface of CS8 and interface of mating part or bushing.

C. Place one hand on the power cable directly below CS8 and one hand on the body of the CS8. Lifting together, push CS8 onto mating part, lining up the

hole in the lug with the stud on the mating part.

D. Insert Hex tool (P620AT or equivalent

5

/

16

" hex tool) into loadbreak interface and engage faster. Rotate tool 2-3 turns to start thread engagement.

!

CHECK: Tug on power cable to confirm stud is through hole in lug. Only a small amount of movement should be possible. If the cable

moves more than a small amount repeat steps above.

E. Continue rotating hex tool. Torque fastener to 20ft-lb (P620AT Tool has built in 20ft-lb torque limiter.)

!

CHECK: As a final check, tug on power cable. This should result in no movement at all.

STEP 15-Mating Deadbreak Interface

STEP 14- Inserting Hex Tool

Product Family

R800

Installation Instructions

Clean and Lubricate

(Internal Cavity)

Clean and

Lubricate

Mating Part or

Bushing

Stud

Torque

Grasp and lift

from here