北京锐志天宏科技股份有限公司

Beijing RichAuto S&T Co., Ltd.

34

Forging ahead, create future together!

5.3.4

Manual switching coordinate system

Including

machine coordinate system

and

work coordinate system

.

Machine coordinate system is a fixed position, the origin point of machine coordinate is

always a fixed position relative to the machine; its coordinate value is called mechanical values,

the origin of coordinate is the origin of the machine or called reference point. So, at any time, a

point in space can be uniquely determined by a mechanical coordinate system. Because of

reference point is the calculation basis of machine coordinates movement, all of those operations

such as power on the machine or abnormal release and so on have to return to the reference

point which is refers to return machine ZERO.

Work coordinate system used more greatly than other coordinates system in processing.

Usually, in processing, we describe a processing position is always relative to a certain point on

the workpiece, whereas the workpiece on the machine tool's position relative to the mechanical

origin is often change, so it is necessary to introduce a set of more convenient coordinate system

during processing, that is work coordinate system. The origin of work coordinate system is a fixed

point relative to the workpiece, but it is floating relative to the machine coordinate origin.

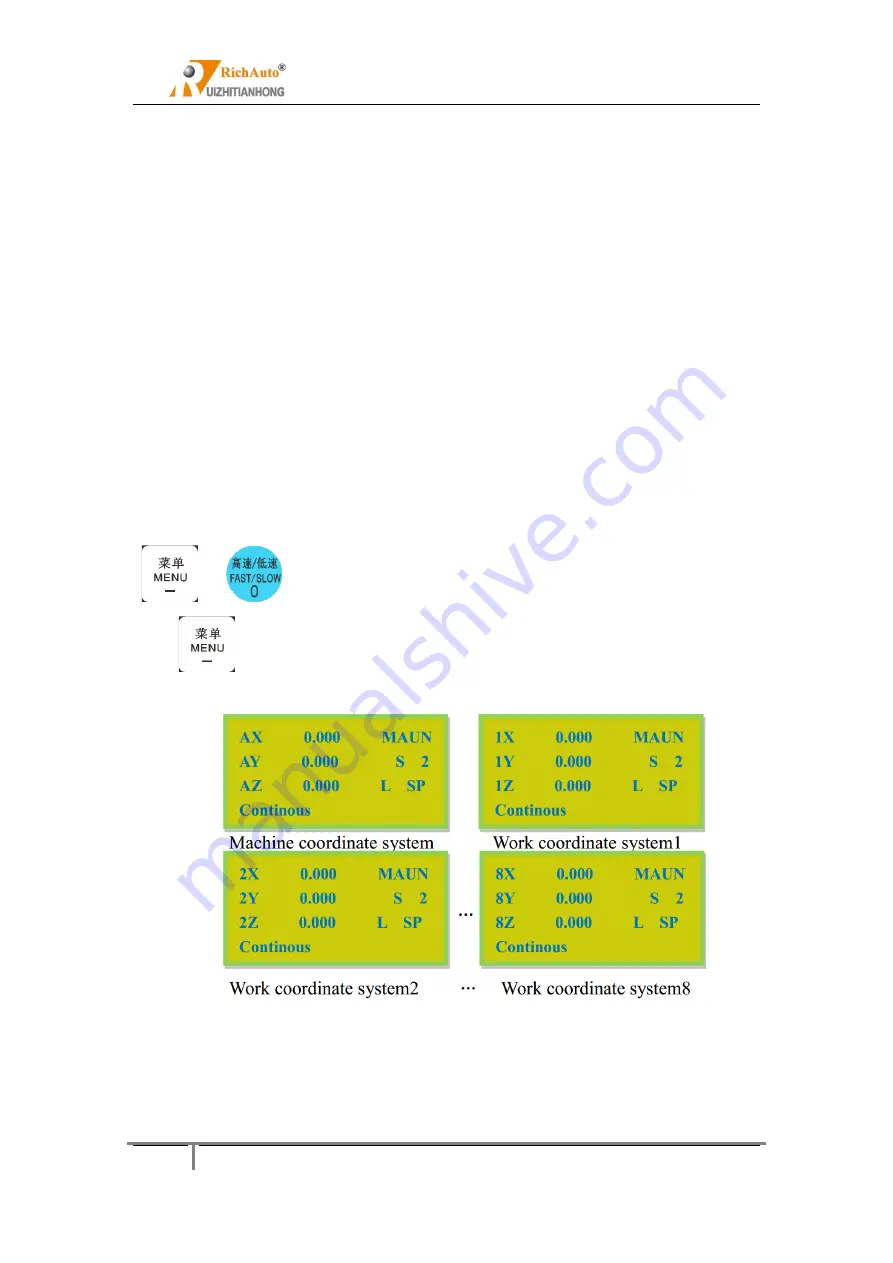

RichAuto-B18

provides 1 machine coordinate system and 9 work coordinate systems. Press

“

” + “

” can switch the machine coordinate system and work coordinate system;

press “

” + “Number button 1-9” can switch among different work coordinate systems.

Schematic diagram of coordinate system:

Note

: The system cannot set workpiece origin under machine coordinate system. User should

switch to work coordinate first, and then set workpiece origin.