北京锐志天宏科技股份有限公司

Beijing RichAuto S&T Co., Ltd.

54

Forging ahead, create future together!

to X7-E-stop signal.

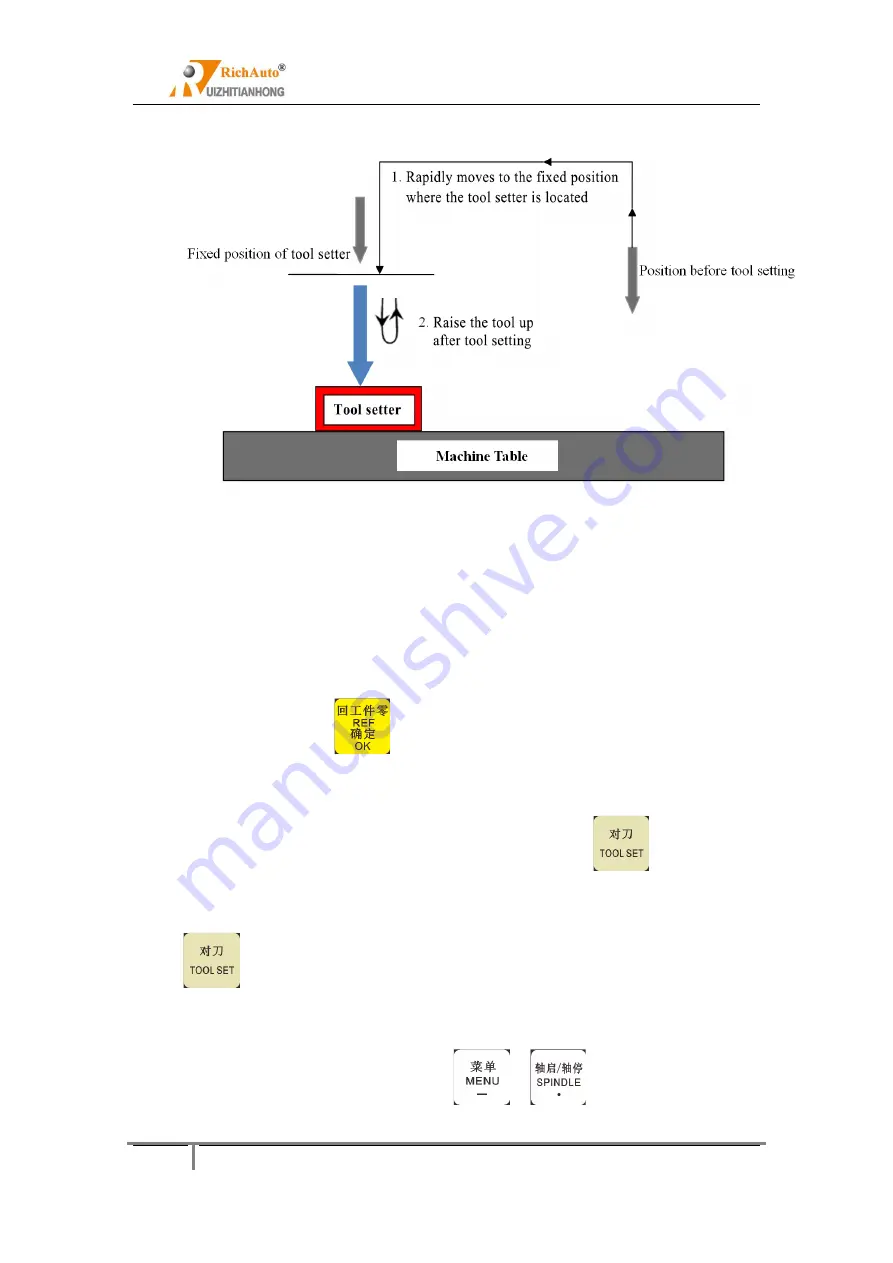

Fixed calibration diagram:

Fixed calibration

: Means to execute tool setting operation at a certain fixed position on the

machine table.

During machining, the cutter tool wear or fracture that needs replacement. However, the blade

length and tool clamping position will change after tool changing. The system can execute “fixed

calibration” to re-confirm the tool offset value.

Instructions

:

1)

Set Tool setter position

Get into “MACHINESETUP--C.A.D Position” to set Tool setter position, including

“Inplace”&“Inposition”.

In position(positioning): Press“

”, screen displays “Press OK key to set point position by

manual mode, it’s very simple but not accurate, press cancel to set by number”. Recommend to

choose manual mode.

In place: Move X,Y axis to the place where is over the Tool setter, press “

”.

2)

First time tool setting / Tool setting after tool changing

Manual move Z axis to the surface of workpiece, and set workpiece origin of X, Y, Z, A axis.

Press “

”execute the first time tool setting. The system will record value of offset

automatically.

Start the processing after first time tool setting.

After the tool changed or tool bit broken, press “

”+“

” to start second time tool

setting, system will automatically restore to current Z axis workpiece coordinate origin.