Beijing RichAuto S&T Co., Ltd.

1

Foreword

System introduction:

RichAuto CNC motion control systems are independently developed by Beijing RichAuto S&T

Co., Ltd. It can be widely applied to machinery, advertisement, woodworking, mold engraving

machines, laser, flame, plasma cutting machines, woodworking lathe, dispensing machine and

soon in the industry machine control field.

RichAuto make DSP as the core control system

,

High-speed processing operation which are

the microcontroller, PLC systems can’t match

;

Embedded structure

,

High degree of integration,

Strong stability, easy to installation and operation

;

support U disk, Removable storage card

reader

,

With USB Interface

,

High speed transfer

,

Plug and play . Fully offline work.

Performance characteristics:

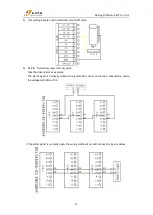

1. System standard configuration is X, Y, Z axis motion control method, and supports the rotation

axis

(

C axis

)

control which enables the switch between rotary machining and plane processing .

Can be extended to X, Y, Z, C four-axis motion control to realize 4 axes linkages control.

2. Multiple I/O ports control. Standard equipped with I/O signal node which has 8 inputs and 7

output signals.

3. Support the standard G code, PLT format instructions; support domestic and international

mainstream CAM software, such as: Type3, Artcam, UG, Pro/E, MasterCAM, Cimatron, Ucancam

etc.

4. Provide with power failed protection. System automatically save the current processing

information in the moment of sudden power down (file name, current line number, work speed,

spindle state)

;

After powered up and returned HOME position, the system automatically prompts

the user to restore the processing before power down which makes processing operations

become more humanity.

5. Support breakpoint memory, select file line No. processing. Can save 8 different breakpoint

processing information.

6. Multi-coordinate memory function. Provide 9 working coordinate system. The User can switch

among the 9 coordinates, each coordinate system can save a process origin information.

7. Support adjusting spindle operating frequency (or spindle rotate speed). The spindle frequency

is divided into 8 shifts. During processing, user can adjust shifts directly by keys without suspend

processing.

8. Support adjust speed ratio during operation. To adjust the speed ratio so as to change the

processing speed and travel speed, speed ratio values from 0.1-1. Increasing or decreasing 0.1 per

time.

9. Simple manual operate mode. In manual mode, the system provides 3 kinds of move modes,

including continuous, step (crawl), distance, become more simple and convenient.

10. Identifies M code, F code and other extended instructions, and it can also open a special code

based on user’s needs.

11. Built-in 512 M memory. Adapt USB communication port with high efficiency for file transfer.

Can read files in U disk and card reader directly.