Manual

63300841

3

0

Troubleshooting / operating errors

You are able to see errors and operating errors in the status messages of the LED display and then

correct them accordingly.

Reset should be carried out in the case that other non-defined conditions arise and the lock does not

operate faultlessly even though the battery has been replaced. This resets the lock to factory default

settings and all programming is deleted.

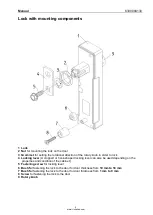

Replacing the battery

1.

TG

Loosen the screw on the side of the cover

(using a

T6x60 mm Torx screwdriver

).

2. Open the battery compartment and remove the

battery pack. Disconnect the two-pole plug-in

connector from the battery pack.

3. Connect the new battery pack to the plug-in

connector and insert the battery into the housing.

4. Close the battery compartment and screw down.

Codes are not deleted when a battery is replaced.

Notice: Please dispose the empty battery pack properly in accordance with the valid

environmental regulations!

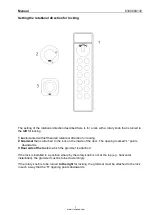

Battery monitoring / battery alarm

Automatic battery monitoring on the SAFE-O-TRONIC

®

63300841

3

0

ensures that with inadequate

battery voltage

he

can no longer be operated.

There is an advance warning when all the LEDs flash twice. In this case it is

recommended

to

replace the battery.

An alarm is triggered after a while if the battery is not replaced. This is indicated when the red and

green LEDs light up in turn three times. The battery

must

now be replaced. In this condition the

compartment can only be opened but no longer locked.

The lock must only be operated using batteries approved. The use of non-approved batteries can

lead to malfunctions and lock damage.

Maintenance and care

The SAFE-O-TRONIC

®

63300841

3

0

is maintenance-free. In no case should the lock be oiled or

greased with lubricants containing mineral oil.

Only use non-stick, residue-free cleaning agents and disinfectants for cleaning purposes. Do not use

any heavy cleaning agents, acids or lyes when caring for the product. Also do not use a pressure

cleaner. It is also not permitted to spray-wash the locks, for example using a hose.

16

www.richelieu.com