GTR211 Installation Manual:

Rev 1

24

J2 Terminal:

Terminal 1:

Optional External Close Push Button Switch.

Terminal 2:

Optional External Open Push Button Switch.

Terminal 3:

Optional External Stop Push Button Switch.

Terminal 4:

Common Terminal for All Optional Push Buttons.

(Hard-Wired keypad connection between terminals 4 & 5)

Terminal 5:

Optional External Open/Stop/Close Single Push Button

(does the 3 open/stop/close functions)

Terminal 6:

Optional External Push Button Pedestrian Switch

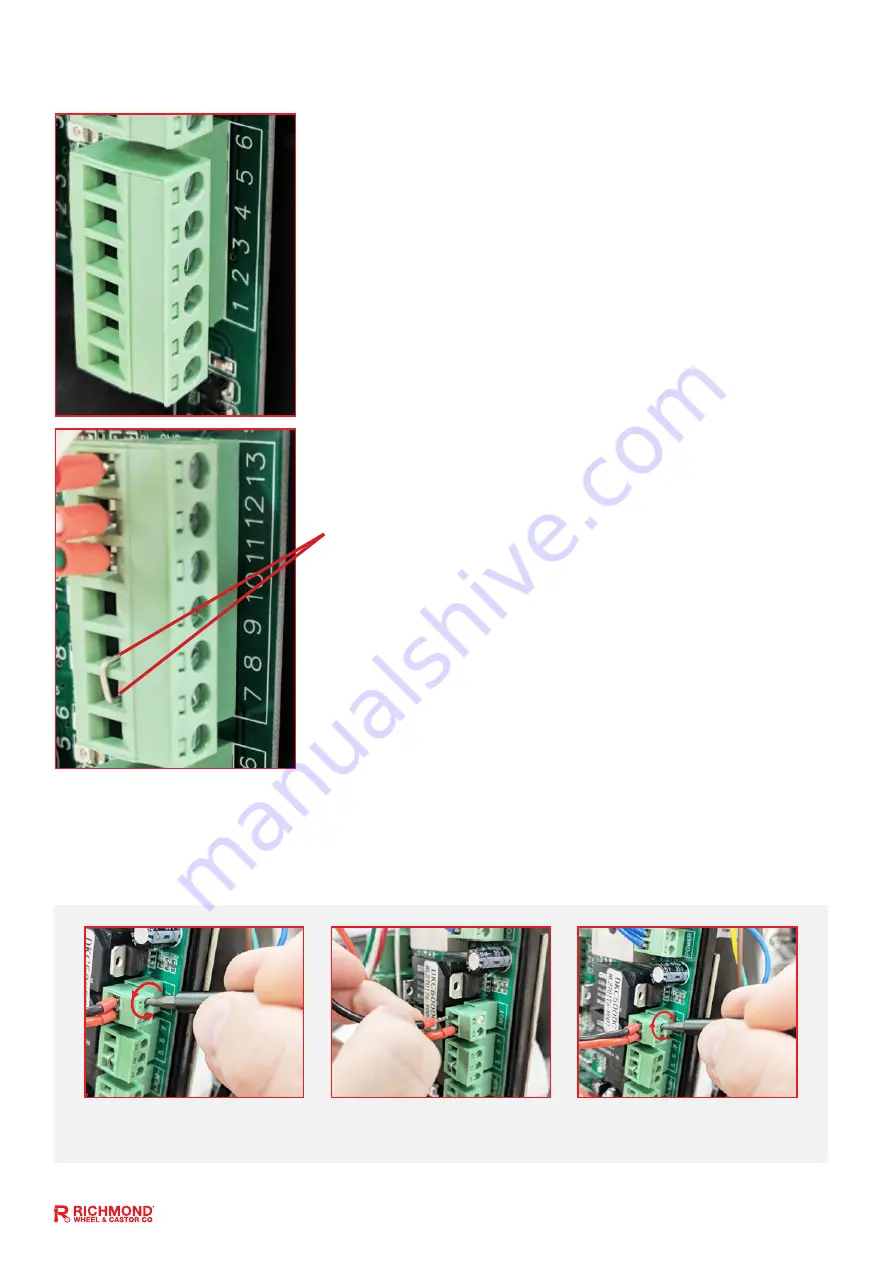

Using a screwdriver, loosen the

screw on the side of the terminal.

Insert the wire into the terminal.

Refer to pages 20 & 21

Tighten with a screwdriver to

secure the wire in place.

How to secure a wire to the circuit board terminals

Ensure that power is off before completing any wiring

All changes to these settings must be completed by a licensed electrician

Please Note: If changing gate direction terminals 11 & 13 on Terminal J5 will need to be swapped.

J5 Terminal: Limit Switch and Accessories

Terminal 7:

Power supply for accessories of J5 (+15V)

Terminal 8:

Photocell input (Normally Closed). If no photocell

is fitted use jumper between terminals 8 & 9.

Terminal 9:

Ground/Earth (GND)

Terminal 10:

Exit wand connection between terminals 9 & 10

Terminals 11, 12, and 13 are factory fitted (pre-wired)

Terminal 11:

Close spring limit switch

Terminal 12:

Spring limit switch common terminal

Terminal 13:

Open spring limit switch