20 June 2005

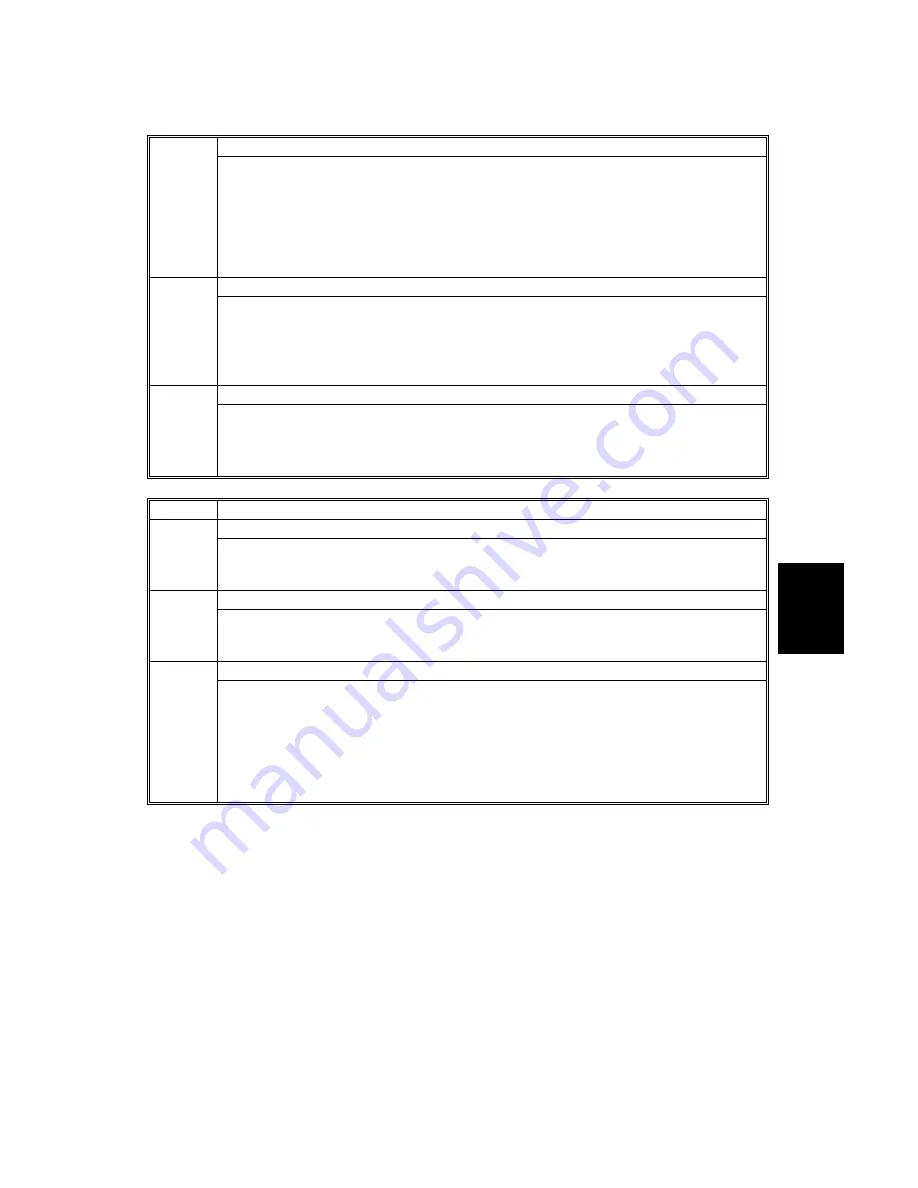

SERVICE PROGRAM MODE TABLES

5-55

Service

Tables

Logout

5839 11

Handles the login request of the login initiator for SBP-2. (1-bit)

Bit0: Off

Bit1: On

OFF: Disable (refuse login). Initiator retry during login. Login refusal on arrival of

login request (standard operation)

ON: Enable (force logout). Initiator retry during login. Login refusal on arrival of login

request, and the initiator forces the login.

Login

5839 12

Enables or disables the exclusive login feature (SBP-2 related).

Bit0: Off

Bit1: On

OFF: Disables. The exclusive login (LOGIN ORB exclusive it) is ignored.

ON: Enables. Exclusive login is in effect.

Login MAX

5839 13

Sets the maximum number of logins from the initiator (6-bits)

[0~63/1]

0: Reserved

63: Reserved

5840

IEEE 802.11b

Channel MAX

5840 6

Sets the maximum range of the bandwidth for the wireless LAN. This bandwidth

setting varies for different countries.

[1~14/1]

Channel MIN

5840 7

Sets the minimum range of the bandwidth for operation of the wireless LAN. This

bandwidth setting varies for different countries.

[1~14/1]

WEP Key Select

5840 11

Determines how the initiator (SBP-2) handles subsequent login requests.

[0~1/1]

0: If the initiator receives another login request while logging in, the request is

refused.

1: If the initiator receives another login request while logging in, the request is

refused and the initiator logs out.

Note

: Displayed only when the wireless LAN card is installed.