Summary of Contents for Aficio MP 1600L2

Page 1: ...Model K C3 5L Machine Code B244 B276 B277 B268 B269 Field Service Manual 3 December 2010 ...

Page 2: ......

Page 12: ...10 ...

Page 14: ...Machine Configuration 1 Product Information 12 1 ...

Page 20: ...1 Product Information 18 1 ...

Page 70: ...2 Installation 68 2 ...

Page 71: ...3 Preventive Maintenance PM Tables See Appendices for the PM Tables 69 3 ...

Page 74: ...7 Wait until the message Completed shows 8 Quit the SP mode 3 Preventive Maintenance 72 3 ...

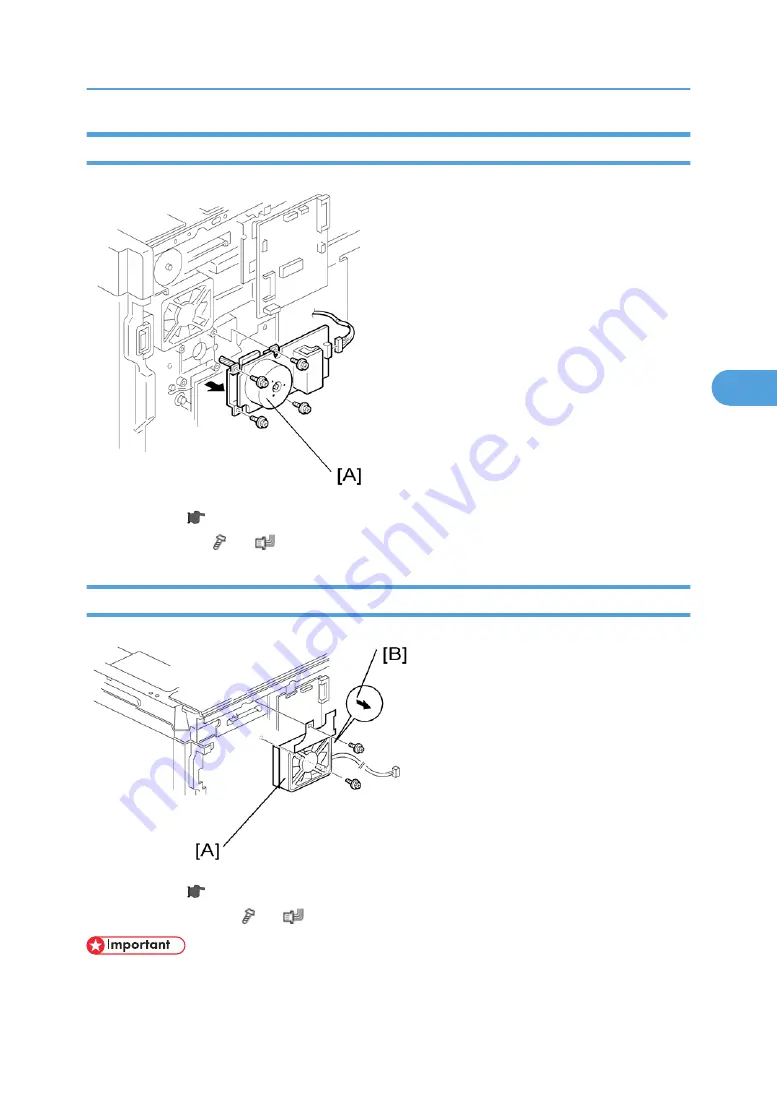

Page 139: ...PSU Power Supply Unit 1 Left cover p 79 2 PSU A All connectors x 6 Other Replacements 137 4 ...

Page 151: ...SP Mode Tables See Appendices for the SP Mode Tables SP Mode Tables 149 5 ...

Page 171: ...1 1 0 0 A5 SEF 1 1 1 0 B5 SEF 1 Detected Using SP Modes 169 5 ...

Page 207: ...Model K C3 5L Machine Code B244 B276 B277 B268 B269 Appendices 3 December 2010 ...

Page 208: ......

Page 210: ...2 ...

Page 228: ...2 Appendix Preventive Maintenance 20 2 ...

Page 262: ...MEMO 54 ...

Page 263: ...MEMO 55 ...

Page 264: ...MEMO 56 EN ...