Service Call Conditions

D096 3-12

SM

Appendix

982 B

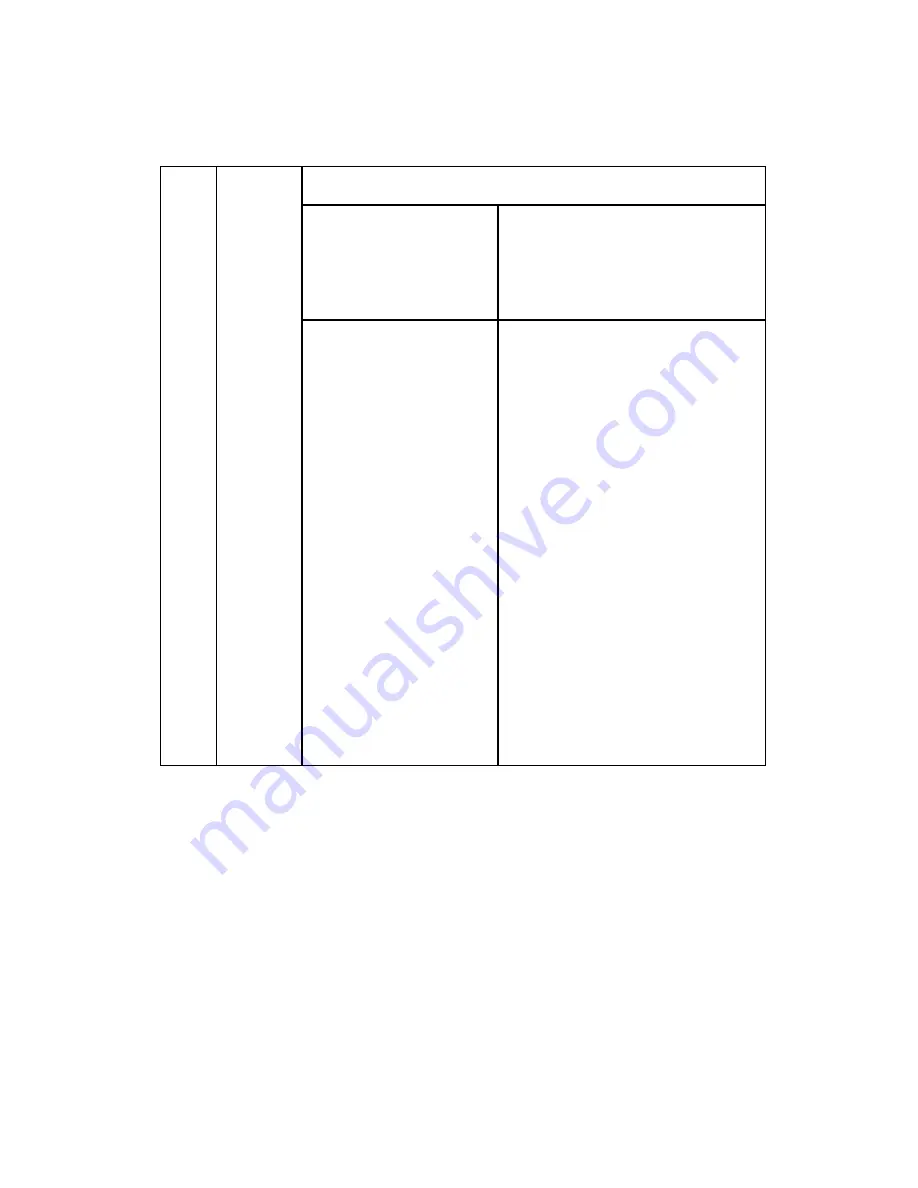

Localization error

The localization settings in

the nonvolatile ROM and

RAM are different

(SP5807).

First machine start after the NVRAM is

replaced

Incorrect localization setting

NVRAM defective

The download (program,

print data, language data)

from the IC card does not

execute normally.

Board installed incorrectly

BICU board defective

IC card defective

NVRAM defective

Loss of power during downloading

Important Notes About SC999

Primarily intended for operating in the

download mode, logging is not

performed with SC999.

If the machine loses power while

downloading, or if for some other

reason the download does not end

normally, this could damage the BICU

or the PCB targeted for the download

and prevent subsequent downloading.

If this problem occurs, the damaged

PCB must be replaced.

Summary of Contents for D096

Page 1: ...D096 SERVICE MANUAL 005627MIU ...

Page 2: ......

Page 3: ...D096 SERVICE MANUAL ...

Page 4: ......

Page 5: ...D096 SERVICE MANUAL 005627MIU ...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 18: ......

Page 20: ......

Page 24: ......

Page 25: ...PRODUCT INFORMATION REVISION HISTORY Page Date Added Updated New None ...

Page 26: ......

Page 30: ...Overview D096 1 4 SM 1 4 OVERVIEW 1 4 1 COMPONENT LAYOUT ...

Page 34: ......

Page 35: ...INSTALLATION REVISION HISTORY Page Date Added Updated New None ...

Page 36: ......

Page 55: ...PREVENTIVE MAINTENANCE REVISION HISTORY Page Date Added Updated New None ...

Page 56: ......

Page 60: ......

Page 61: ...REPLACEMENT AND ADJUSTMENT REVISION HISTORY Page Date Added Updated New None ...

Page 62: ......

Page 110: ...Fusing D096 4 48 SM 4 9 6 THERMOSTAT 1 Hot roller See above 2 Thermostat A x 2 for each ...

Page 127: ...SERVICE TABLES REVISION HISTORY Page Date Added Updated New None ...

Page 128: ......

Page 153: ...TROUBLESHOOTING REVISION HISTORY Page Date Added Updated New None ...

Page 154: ......

Page 161: ...ENERGY SAVING REVISION HISTORY Page Date Added Updated New None ...

Page 162: ......

Page 167: ...D096 SERVICE MANUAL APPENDICES ...

Page 168: ......

Page 170: ......

Page 171: ...APPENDIX SPECIFICATIONS REVISION HISTORY Page Date Added Updated New None ...

Page 172: ......

Page 186: ......

Page 187: ...APPENDIX PREVENTIVE MAINTENANCE REVISION HISTORY Page Date Added Updated New None ...

Page 188: ......

Page 193: ...APPENDIX TROUBLESHOOTING GUIDE REVISION HISTORY Page Date Added Updated New None ...

Page 194: ......

Page 207: ...APPENDIX SP MODE TABLES REVISION HISTORY Page Date Added Updated New None ...

Page 208: ......

Page 244: ......

Page 246: ......