D124

114

Detailed Descriptions

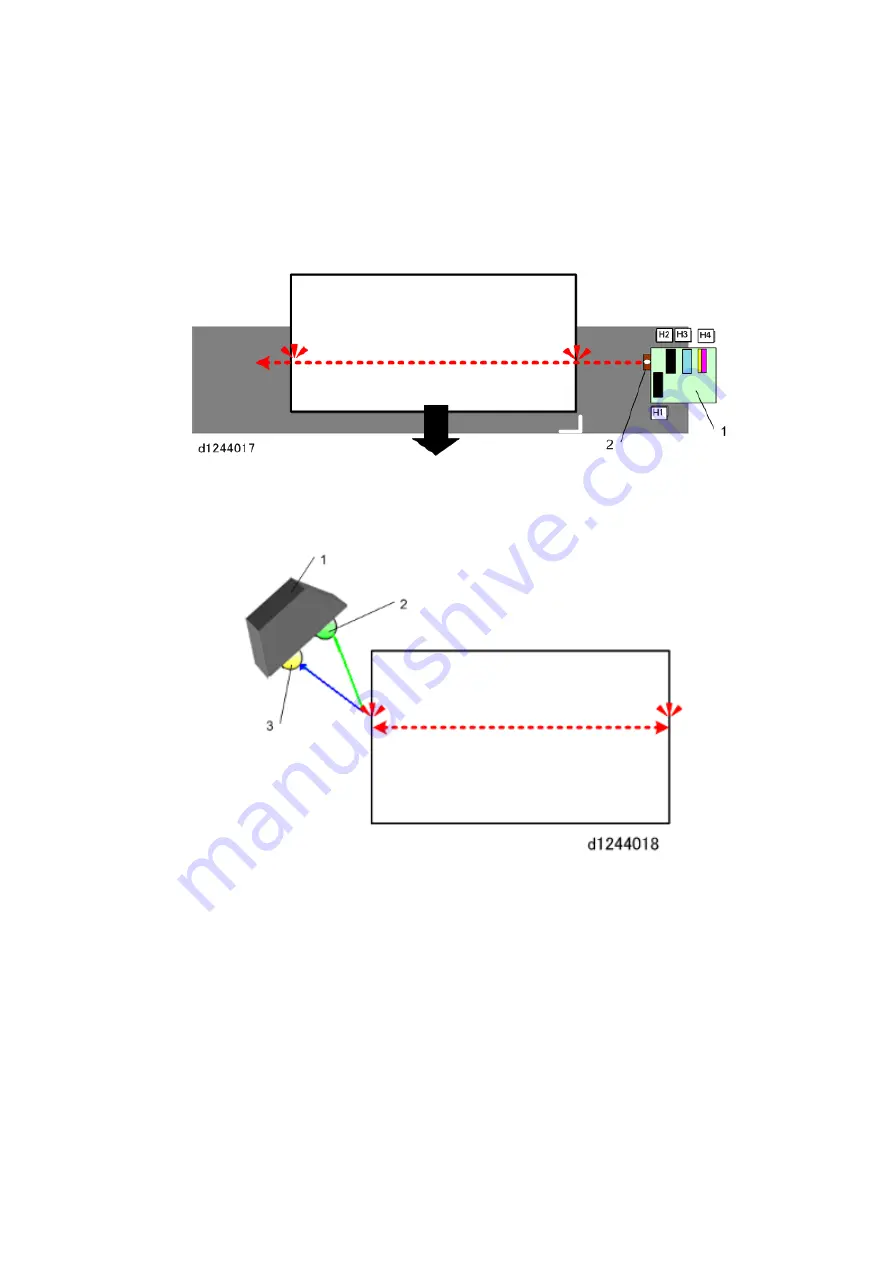

Dot position correction (color registration)

. The carriage moves across the

paper during printing, so the ink drops cannot fall vertically. The readings of the

DRESS sensor are used to adjust the timing of the piezo-electric elements in the

print heads that release the ink. Timing is adjusted for the height of the carriage

(and print heads), paper thickness, speed of the carriage, and print mode

(uni-directional or b-directional).

1. When a job starts, the horizontal motor switches on and moves the carriage (1)

across the paper so that the DRESS sensor (2) can detect the right and left edges

of the paper.

Summary of Contents for D124

Page 1: ...D124 DETAILED DESCRIPTIONS MANUAL ...

Page 2: ......

Page 20: ...D124 14 Detailed Descriptions 1 2 GENERAL LAYOUT ...

Page 24: ...D124 18 Detailed Descriptions 1 4 MOTORS CLUTCHES AIR RELEASE SOLENOID ...

Page 28: ...D124 22 Detailed Descriptions 1 6 ORIGINAL PATH PAPER PATH SENSORS ...

Page 62: ...D124 56 Detailed Descriptions 3 1 2 SCAN JOB IMAGE DATA FLOW 3 1 3 PRINT JOB IMAGE DATA FLOW ...