31 March, 1997

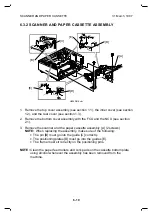

SCANNER AND PAPER CASSETTE

6-11

Replacement

Adjustment

— CONTACT IMAGE SENSOR (CIS) AND PAPER END SENSOR —

NOTE:

The CIS and the paper end sensor are not available separately as

spare parts. Use this procedure only when the CIS or the paper end

sensor has been removed from the machine.

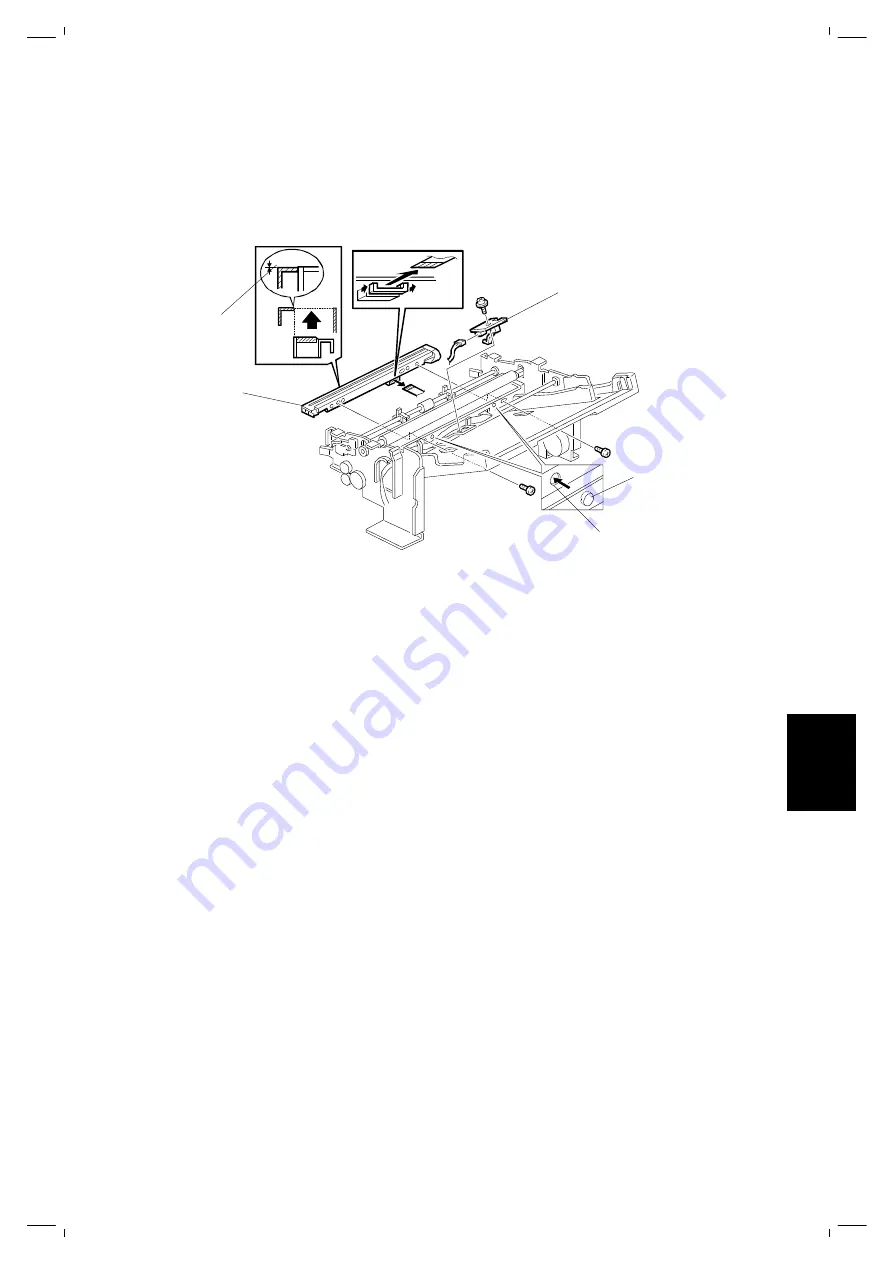

1. Remove the scanner and paper cassette assembly (see section 3.1).

2. Remove the CIS [A] (2 screws, 1 harness).

NOTE:

When replacing the CIS [A], be sure that the dents [B] go into the

openings [C] in the CIS.

The upper front edge of the CIS [D] must not be lower than the CIS

frame surface. Otherwise, document jams occur at this point.

3. Remove the paper end sensor [E].

H905R517.cdr

[A]

[B]

[C]

[D]

[E]