Summary of Contents for FAX07

Page 4: ...SECTION 1 ...

Page 8: ...SECTION 2 ...

Page 12: ...SECTION 3 ...

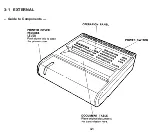

Page 13: ...3 1 EXTERNAL Guide to Components 3 1 ...

Page 14: ...3 2 INTERNAL Optical and Mechanical Components 3 2 ...

Page 16: ... Electronic Components 3 4 ...

Page 19: ...SECTION 4 ...

Page 52: ...Paper Leading Edge 4 3 3 ...

Page 54: ...SECTION 5 REMOVAL AND REPLACEMENT ...

Page 67: ...SECTION 6 ...

Page 74: ...SECTION 7 ...

Page 77: ...SECTION 8 T R O U B LE S H O O T I N G ...

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ...A H ...

Page 142: ... BIT SW 1C BIT No o 1 2 3 4 5 6 7 Function Remarks Not used Not used A 36 ...

Page 145: ...APPENDIX C POINT TO POINT DIAGRAM I C 1 ...

Page 146: ...APPENDIX D BLOCK DIAGRAMS 1 System Control D 1 ...

Page 147: ...2 Video Data Path Transmission D 2 ...

Page 148: ... Reception D 3 ...

Page 149: ... Copying D 4 ...

Page 150: ... Video Processing Circuit D 5 ...

Page 151: ...3 Communication Control D 6 ...

Page 152: ...4 Power Supply Distribution D 7 ...

Page 153: ... PSU D 8 ...

Page 154: ...APPENDIX E PCB LAYOUTS FCU 1 4 Parts Layout E 1 ...

Page 155: ...FCU 2 4 Parts Side E 2 ...

Page 156: ...FCU 3 4 Comp Side E 3 ...

Page 157: ...FCU 4 4 Reverse E 4 ...

Page 158: ...NIF 1 4 Parts Layout ...

Page 159: ...NIF 2 4 Parts Side E 6 ...

Page 160: ...NIF 3 4 Comp Side E 7 ...

Page 161: ...NIF 4 4 Reverse E 8 ...

Page 162: ...PSU 1 2 E 9 ...

Page 163: ...PSU 2 2 Reverse E 10 ...

Page 164: ...SBU 1 4 Parts Layout E 11 ...

Page 165: ...SBU 2 4 Parts Side E 12 ...

Page 166: ...SBU 3 4 ...

Page 167: ...SBU 4 4 Reverse E 14 ...