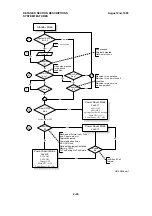

4. Sending a Fax Message or Copying in Power Saver Mode

The flow chart on the next page explains how the machine wakes up from

power saver mode upon a manual operation, and how it comes back to a

power saver mode.

Manual Wakeup Conditions

While the machine is in a power saver mode, either the power saver CPU

(Level 2) or the main CPU (Level 1) monitors signals from the following (con-

dition #1 on the flow chart).

•

Power saver key

•

Document sensor

•

Off-hook detector on the NCU

When a signal from one of these has been detected, the CPU wakes up all

the components and the machine enters normal operating mode, even during

the Night Timer period.

After operations have been finished, the machine goes back to a power saver

mode as explained in the previous sections.

August 2nd, 1995

DETAILED SECTION DESCRIPTIONS

SYSTEM FEATURES

2-53