31

Ricoh Co. Ltd.

http://www.ricoh.com/

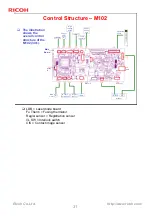

Control Structure – M102

The illustration

shows the

overall control

structure of the

M102 (3in1).

M

High

voltage

board

M

LDB

Polygon

motor

ID chip

Feed

solenoid

Power

supply

unit

Operation

panel

USB

Scanner

CIS

Motor

I/L SW

Regist

sensor

Fu Therm /

Exit sensor

Main

motor

Main

Board

Debug I/F

Debug

I/F

Debug I/F

LDB = Laser diode board

Fu Therm = Fusing thermistor

Regist sensor = Registration sensor

I/L SW = Interlock switch

CIS = Contact image sensor