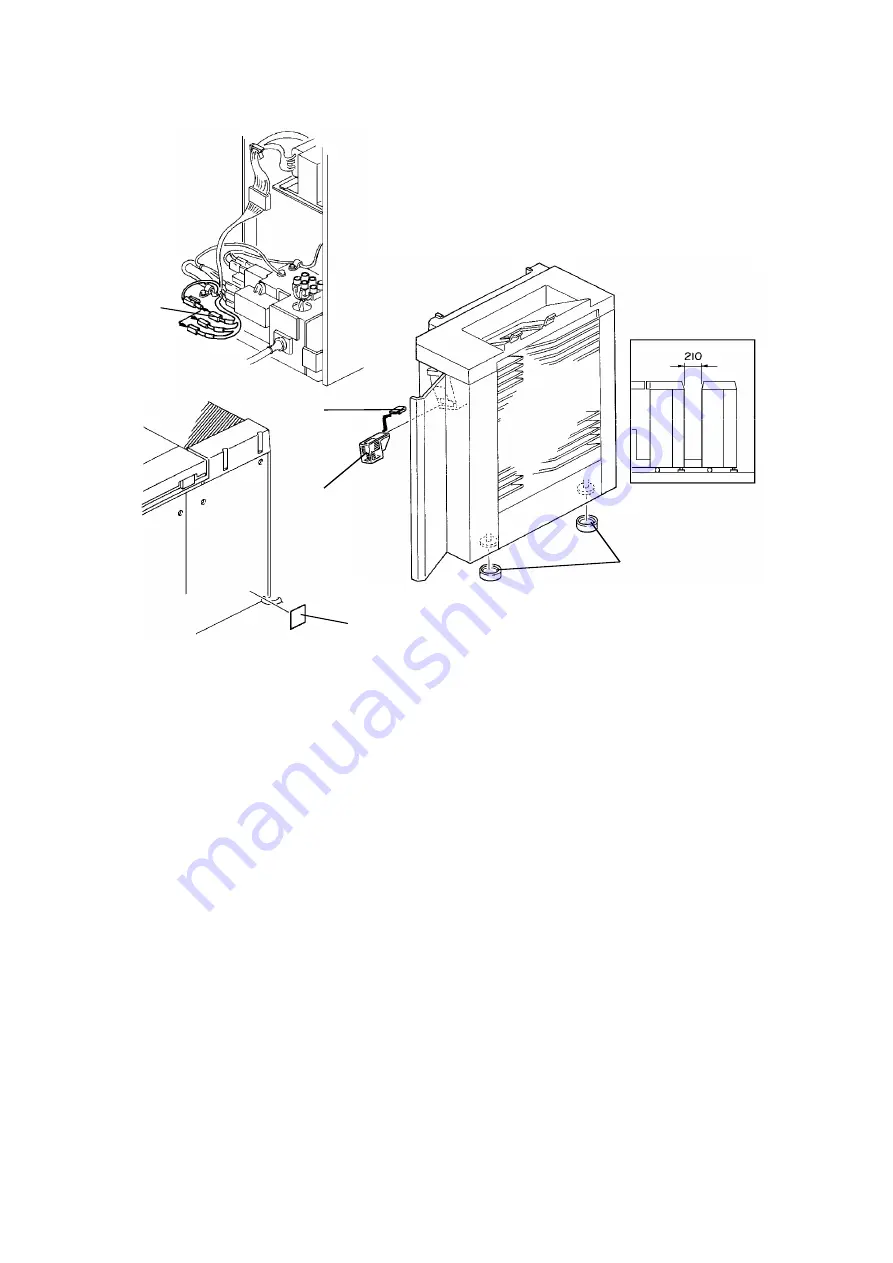

28. 220/230/240 V version only

If the voltage of electrical power supply from wall outlets is 220 V or 240

V, change the voltage as follows:

a) Disconnect the input line [A] from the 230 V connector.

b) Connect the input line to the appropriate voltage (220 V or 240 V).

29. Reinstall the rear cover.

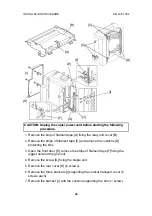

30. Put the two leveling shoes [B] under the feet. Confirm that the sorter is

parallel to the copier and the 1st sorter stapler.

31. Stick the decal [C] on the left rear cover of the copier beside the power

cord.

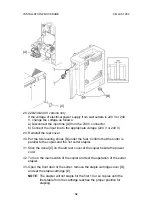

32. Turn on the main switch of the copier and test the operation of the sorter

stapler.

33. Open the front door of the sorter, remove the staple cartridge cover [D],

and set the staple cartridge [E].

NOTE:

The stapler will not staple for the first 10 or so copies until the

first staple from the cartridge reaches the proper position for

stapling.

[D]

[E]

[B]

[C]

[A]

INSTALLATION PROCEDURE

6 March 1992

32

Summary of Contents for ST23

Page 1: ...RICOH ST23 SERVICE MANUAL ...