T

echnical

B

ulletin

PAGE: 2/3

Reissued:27-Mar-14

Model:

Taurus-C1a/C1b (D074/D075)

Date:

26-Jan-14

No.:

RD074115a

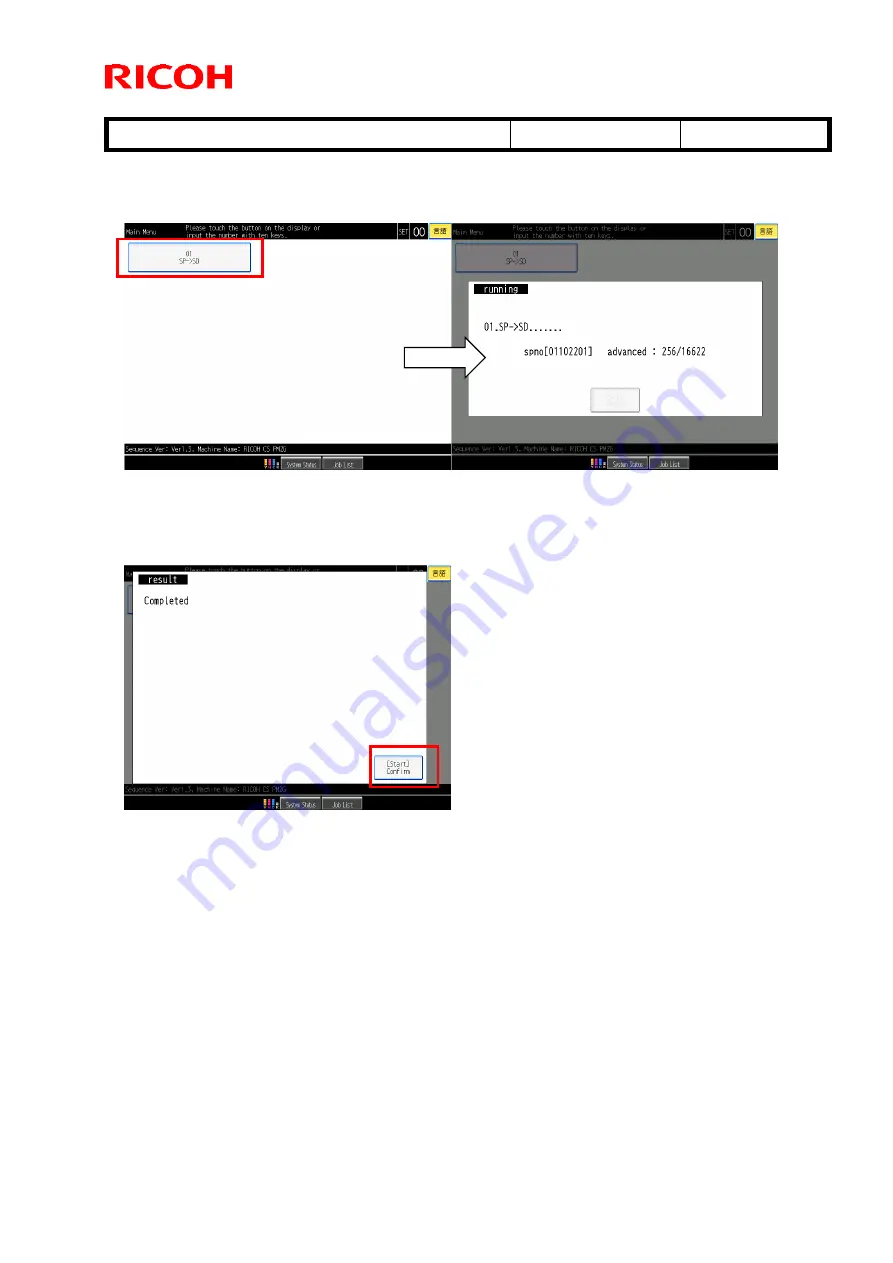

4. Touch “01 SP->SD” on the operation panel and wait approximately 1 minute for the

download process to complete.

5. When successfully downloaded, the operation panel displays “Completed”.

Touch “[Start] Confirm”

to exit.

5. Turn off the machine and remove the SD card from the card slot.

6. In the SD card, the SMC data is saved with the following naming convention:

splist_

[Serial Numbers]

_

[Date/Time when the SMC is taken(YYYYMMDDHHmmss)]

.csv

Example

: splist_

V9000500010

_

20130926063542

.csv