T

echnical

B

ulletin

PAGE: 2/3

Model:

Taurus-C1/P1 (D074/D075/M044)

Date:

19-Oct-11

No.:

RD074025

D

Temporary Solution

How to check if the Lens Assembly unit is set properly

1. Do SP2111-004 (Forced Line Position Adj – Mode d) to execute MUSIC.

2. Check the results in SP2181-014~022 (Alignment Result) and take note of the values.

SP

Description

2181-014

Difference Sub Left: C

x

2181-015

Difference Sub Center: C

y

2181-016

Difference Sub Right: C

z

SP

Description

2181-017

Difference Sub Left: M

x

2181-018

Difference Sub Center: M

y

2181-019

Difference Sub Right: M

z

SP

Description

2181-020

Difference Sub Left: Y

x

2181-021

Difference Sub Center: Y

y

2181-022

Difference Sub Right: Y

z

3. Calculate the misalignment level by applying the above results to the following formula:

(x + z) / 2 – y

4. If the absolute value obtained from the above calculation is higher than “75”, the Lens

Assembly unit is out of position. Follow the procedures described in “Setting the Lens

Assembly Unit”.

If the absolute value obtained from the above calculation is lower than “75”, the Lens

Assembly unit is set properly.

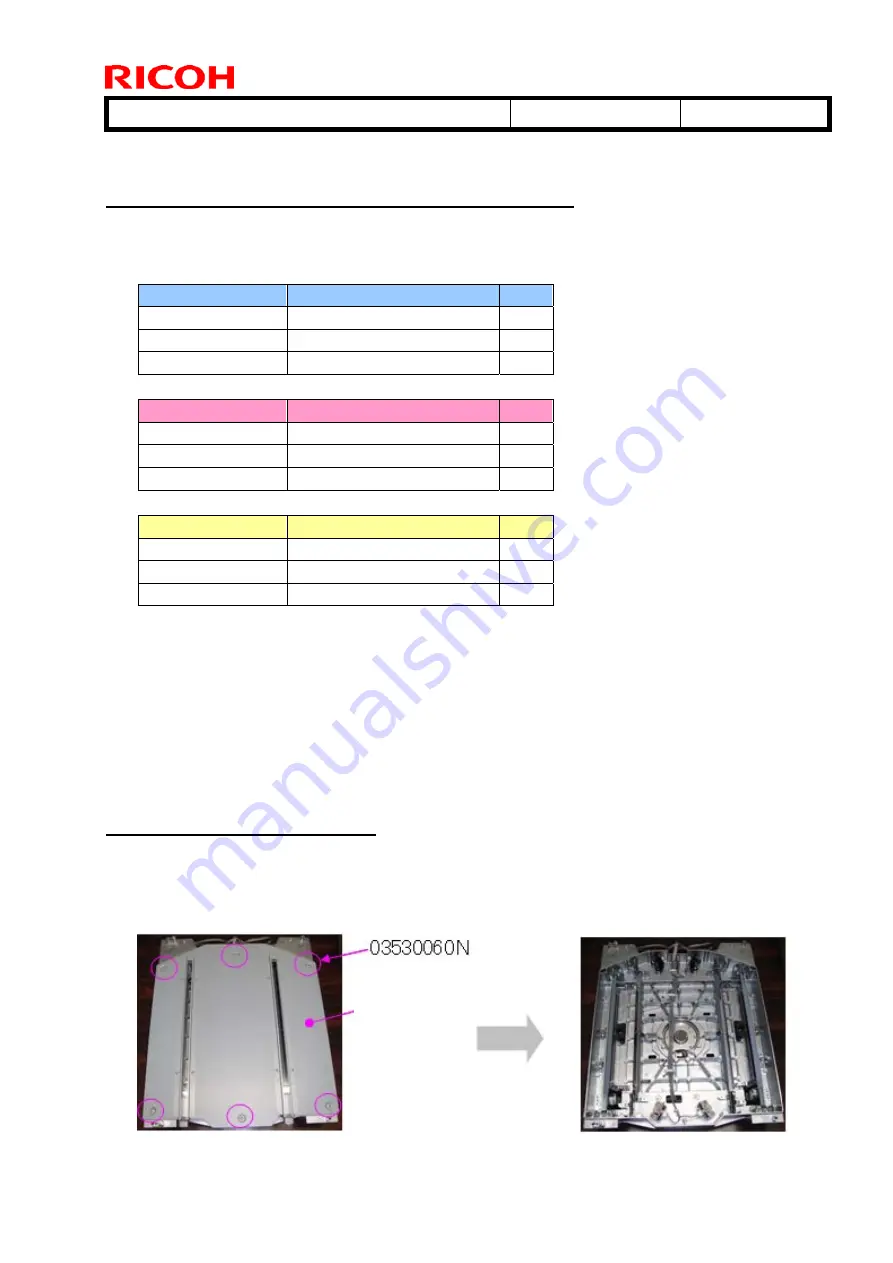

Setting the Lens Assembly Unit

1. Remove the laser unit from the machine. (See “4.Replacement and Adjustments >

Laser Unit > Laser Units” in the field service manual).

2. Place the laser unit upside down on a flat surface.

3. Remove the bottom cover. (screw x6)

Bottom cover