Manual Operation:

The

LevelTow

Compressor System also has a manual control function. This function allows you to manually

infl ated or defl ate the system. To use the manual function you must fi rst turn the system off by pushing the

main power button. Once the system is turned off you can push the rocker switch up to infl ate or down to

defl ate. To put the system back in level mode push the main power switch to turn it back on.

Note:

If the Activation Button is illuminated blue and the manual button is pushed the truck will relevel itself. The

activation button has to be off for the manual control to be used and the truck remain at the height.

Troubleshooting:

If after installation you fi nd the system not functioning correctly, you may have the sensor operating the wrong

direction. You can verify this by turning the truck on and check that the activation button is illuminated blue.

Unhook one end of the linkage and move the sensor arm by hand. If when you move the arm down (Keep in

mind there is an 20 second delay) and the Air spring infl ates, the sensor is operating in the wrong direction.

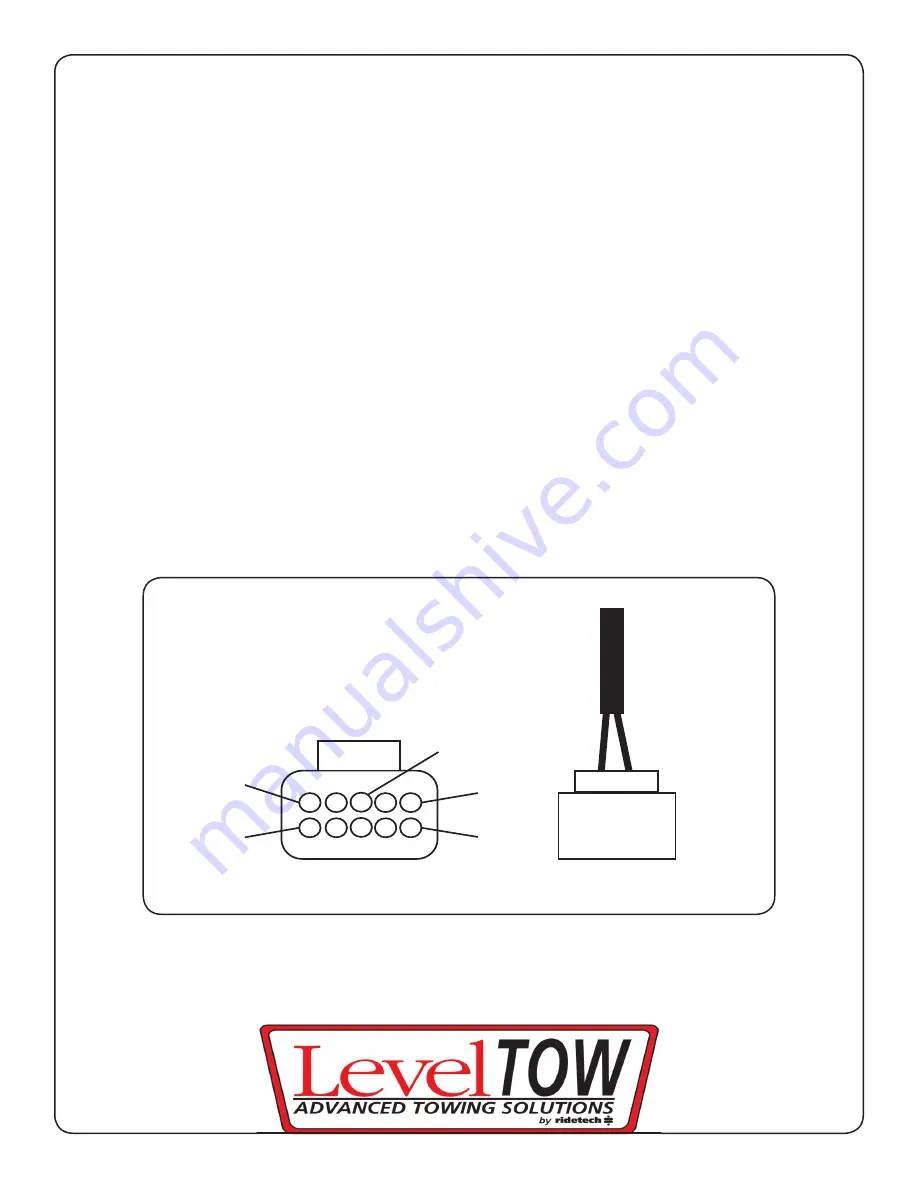

You can fi x this problem without remounting the sensor by swapping the blue and green wires in the har-

ness at the sensor. To do this, with the truck turned off , simply unplug the harness from the sensor. Using

a small screwdriver pop the purple retainer out of the plug by prying up on each end of it. After removing the

retainer if you look into the end of the plug you will see a tang holding each wire terminal. Simply pry it down

just enough to release the terminals of the blue and green wires. Swap the blue and green wire postion and

reinstall the wires into the plug paying attention to the direction of the small tab on the wire terminal. This

tab will point to the center of the plug. Push the wire terminals into the plug making sure they catch on the

tang and reinstall the purple retainer. After plugging the sensor back in you can confi rm correct operation by

turning the truck back on moving the sensor arm up, the Air spring should infl ate. If the system is functioning

correctly, shut the truck off and reattach the linkage.

STILL HAVE QUESTIONS?

Tech line hours

Monday-Friday

8AM - 6PM (EST)...........812-482-2932

Page 8

#82010009

RED

RED

BLACK

BLUE

GREEN

VIEW FROM WIRE SIDE

WIRE SIDE

SIDE VIEW

WIRE LOCATIONS AT HEIGHT SENSOR

Summary of Contents for 81214001

Page 2: ...3 8 16 BAIL CLAMP ...