ENG

Page 4

233-Truck-20K-ISM-RevB-07-06-18

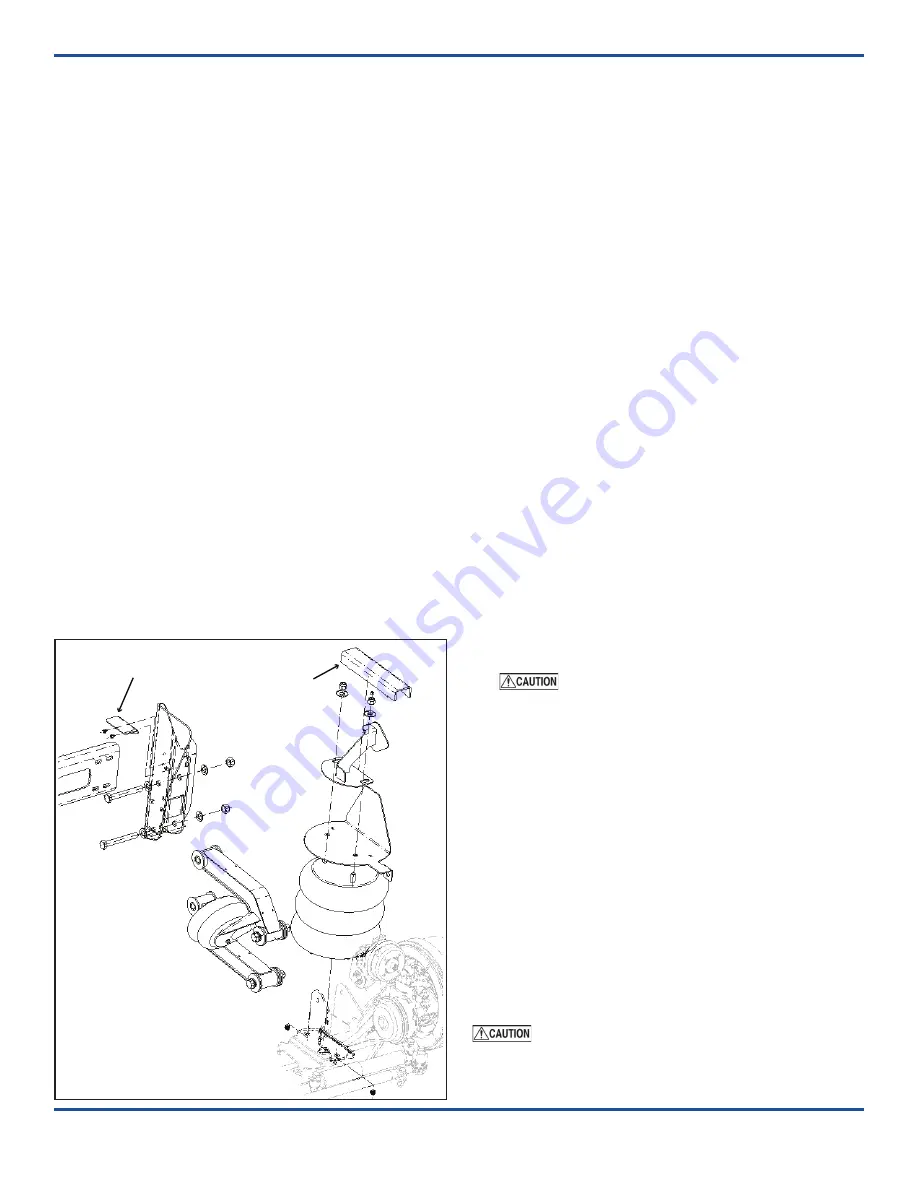

Mounting the suspension to the frame

Refer to the engineering drawing for the range of ride

heights available as well as spacing and clearance

requirements of the suspension.

The RSS-233 20K Truck Suspension is shipped fully

assembled. If the suspension system is taken apart

for installation, the components must be reassembled

with the proper torque applied (Appendix).

Bolt-On Installation Procedure

Suspension hangers are attached to the vehicle frame

with six 5/8-inch Grade 8 bolts in each hanger. Air

spring mounting brackets require two 5/8-inch Grade

8 bolts in each bracket. Flanged lock nuts or lock nuts

with hardened washers are required.

•

Hanger locator flanges are pre-installed to

match the ride height set by the air spring

mounting plate.

Ride height is adjusted by installing a 1” or 2”

spacer on the air spring mounting plates. The

hanger locator flange is moved up or down on

the hanger to match the height of the air spring

mounting plate and spacer installation.

• A 2” spacer kit for both the hangers and air

spring mounting plates is available for the 233-

20K disc brake and roll-off configurations.

1. Measure the vehicle frame width and the hanger-

to-hanger inside dimensions of the suspension.

Customer-supplied filler plates are required for

the hangers and air spring mounting brackets if

the vehicle frame width is narrower than that of

the suspension.

2. Place the suspension (with hanger and air spring

filler plates and the appropriate spacer(s), if re

-

quired) in the desired location.

NOTE: A crossmember must be located on the

frame within six inches of the leading or trailing

edge of the hanger.

3. Check that the location provides adequate clear-

ance for suspension components. Make sure the

top of the hangers and air spring mounting plates

are parallel to the chassis frame to maintain the

proper caster angle.

4. Hangers and air spring mounting plates should

be perpendicular to the chassis frame and in

alignment with each other. Clamp the hangers,

mounting plates, and spacer and filler plates (if

required) firmly in place.

5. Refer to the engineering drawing for the recom-

mended bolt hole locations on the hangers and

air spring mounting plates. If it is not possible to

use the recommended bolt locations, space the

bolt holes as far apart as possible to provide the

greatest support for the suspension.

Check to make sure that wires, hoses or

other components located within the frame rail

are not affected by drilling.

6. Center punch and drill six bolt holes in each

hanger. Bolt the hangers to the frame with the

recommended Grade 8 bolts and lock nuts.

7. Center punch and drill two bolt holes in each

air spring mounting bracket. Bolt the air spring

brackets to the frame with the recommended

Grade 8 bolts and lock nuts.

8. Install/connect the air control kit (ACK) to the

suspension (Page 6). Check the air system after

installation for leaks and proper operation of

controls.

9.

Perform final assembly and inspection and check

the wheel toe setting (Page 5)

Failure to torque bolts/nuts of suspension

components to specifications can result in failure of

the suspension and void the warranty.

NOTE:

Air Spring Spacer

must be used

if hanger locator flange

is moved from

factory pre-set

ride height

Hanger Locator Flange-(RH)

Flanged Screw (Self-Tapping)

2” Spacer

(Air Spring)