Step (3)

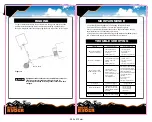

Refer to Figure 8 for wiring diagram.

Route the short red and black colour coded wires from the control box to the

motor. Route the long red and black colour coded wires from the control box

to the battery. Attach the circuit breaker to battery end of the red wire. Wrap

the circuit breaker with electrical tape to prevent accidental short circuits.

Apply several layers of electrical tape where wiring may come into contact

with sharp metal parts of the vehicle to prevent insulation abrasion or

cutting.

Attach the circuit breaker to the battery positive terminal. Connect the

remaining black control box wire to the battery negative terminal. Open the

cover on the control box, attach the remote control to the control box.

Step (4)

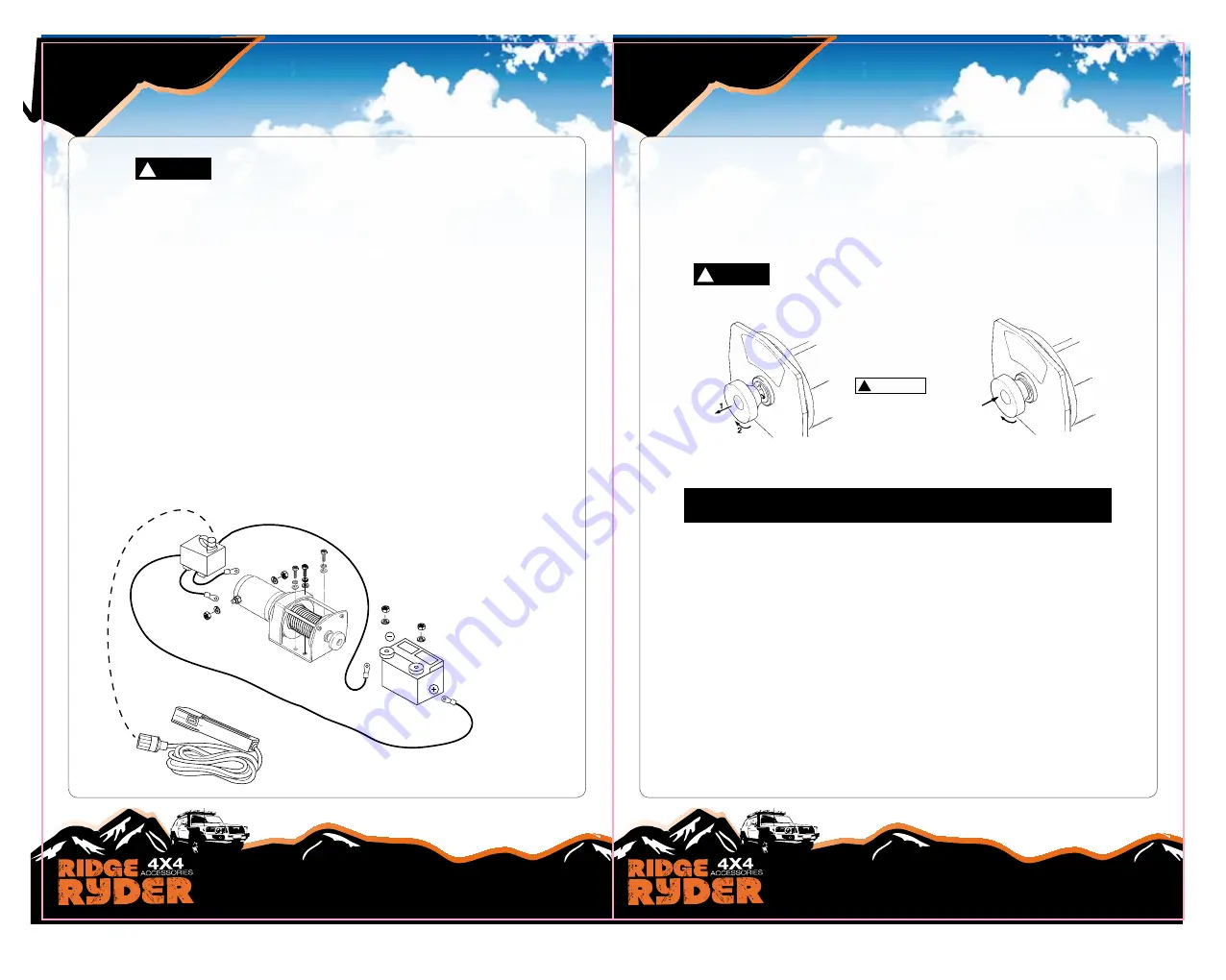

FREESPOOL OPERATION

Pull and turn the clutch knob to the “Free ” position as shown in Figure 9.

If there is a load on the winch rope, the clutch knob may not pull out easily.

DO NOT FORCE THE CLUTCH KNOB. Release tension on the clutch by jogging

out some of the winch rope. Release the clutch and pull out the winch rope and

Batteries contain gasses which are flammable and

explosive. Wear eye protection during installation and

remove all metal jewellery. Do not lean over battery

while making connections.

Warning

!

(7)

(8)

Clutch must be fully engaged before winching. Never

engage clutch knob while drum is turning.

Caution

!

secure to anchor or load. Check that there are at least five (5) turns of winch

rope left on the drum. Re-engage the drum by returning the clutch

knob to the “Engaged” position. (See Figure 9). Activate the winch in Cable

Out momentarily to check drum rotation direction. If the drum rotates in the

wrong direction, recheck your wiring.

DYNEEMA ROPE

1. The life of the dyneema winch rope is directly related to the care it receives.

The winch rope on a new winch, and any replacement ropes, should be

respooled under a minimum of 100 lb load before using the winch. Failure to do

this will result in winch rope damage. Inspect winch rope before use. Mashed,

pinched, frayed or kinked areas severely reduce the load-carrying capacity.

Replace damaged winch rope.

2. Prevent kinks before they occur.

(a) This is the start of a kink. At this time, the winch rope should be

straightened.

(b) The winch rope was pulled and the loop has tightened to a kink. The winch

rope is now permanently damaged and should not be used .

(c) The result of kinking is that each strand pulls a different amount causing

the strands under greatest tension to break and reduce load capacity of the

winch rope.

Black(-)

Black

Red(+)

Red

Battery

To

Battery

Washer

Washer

Figure 8

to remote control

Engaged

Free

Figure 9

CAUTION

!

If the winch motor

stalls, do not continue

to apply power.

1

2

Step (3)

Refer to Figure 8 for wiring diagram.

Route the short red and black colour coded wires from the control box to the

motor. Route the long red and black colour coded wires from the control box

to the battery. Attach the circuit breaker to battery end of the red wire. Wrap

the circuit breaker with electrical tape to prevent accidental short circuits.

Apply several layers of electrical tape where wiring may come into contact

with sharp metal parts of the vehicle to prevent insulation abrasion or

cutting.

Attach the circuit breaker to the battery positive terminal. Connect the

remaining black control box wire to the battery negative terminal. Open the

cover on the control box, attach the remote control to the control box.

Step (4)

FREESPOOL OPERATION

Pull and turn the clutch knob to the “Free ” position as shown in Figure 9.

If there is a load on the winch rope, the clutch knob may not pull out easily.

DO NOT FORCE THE CLUTCH KNOB. Release tension on the clutch by jogging

out some of the winch rope. Release the clutch and pull out the winch rope and

Batteries contain gasses which are flammable and

explosive. Wear eye protection during installation and

remove all metal jewellery. Do not lean over battery

while making connections.

Warning

!

(7)

(8)

Clutch must be fully engaged before winching. Never

engage clutch knob while drum is turning.

Caution

!

secure to anchor or load. Check that there are at least five (5) turns of winch

rope left on the drum. Re-engage the drum by returning the clutch

knob to the “Engaged” position. (See Figure 9). Activate the winch in Cable

Out momentarily to check drum rotation direction. If the drum rotates in the

wrong direction, recheck your wiring.

DYNEEMA ROPE

1. The life of the dyneema winch rope is directly related to the care it receives.

The winch rope on a new winch, and any replacement ropes, should be

respooled under a minimum of 100 lb load before using the winch. Failure to do

this will result in winch rope damage. Inspect winch rope before use. Mashed,

pinched, frayed or kinked areas severely reduce the load-carrying capacity.

Replace damaged winch rope.

2. Prevent kinks before they occur.

(a) This is the start of a kink. At this time, the winch rope should be

straightened.

(b) The winch rope was pulled and the loop has tightened to a kink. The winch

rope is now permanently damaged and should not be used .

(c) The result of kinking is that each strand pulls a different amount causing

the strands under greatest tension to break and reduce load capacity of the

winch rope.

Black(-)

Black

Red(+)

Red

Battery

To

Battery

Washer

Washer

Figure 8

to remote control

Engaged

Free

Figure 9

CAUTION

!

If the winch motor

stalls, do not continue

to apply power.

1

2

280 x 215mm

Summary of Contents for 341685

Page 1: ...280 x 215mm ...