K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.

7

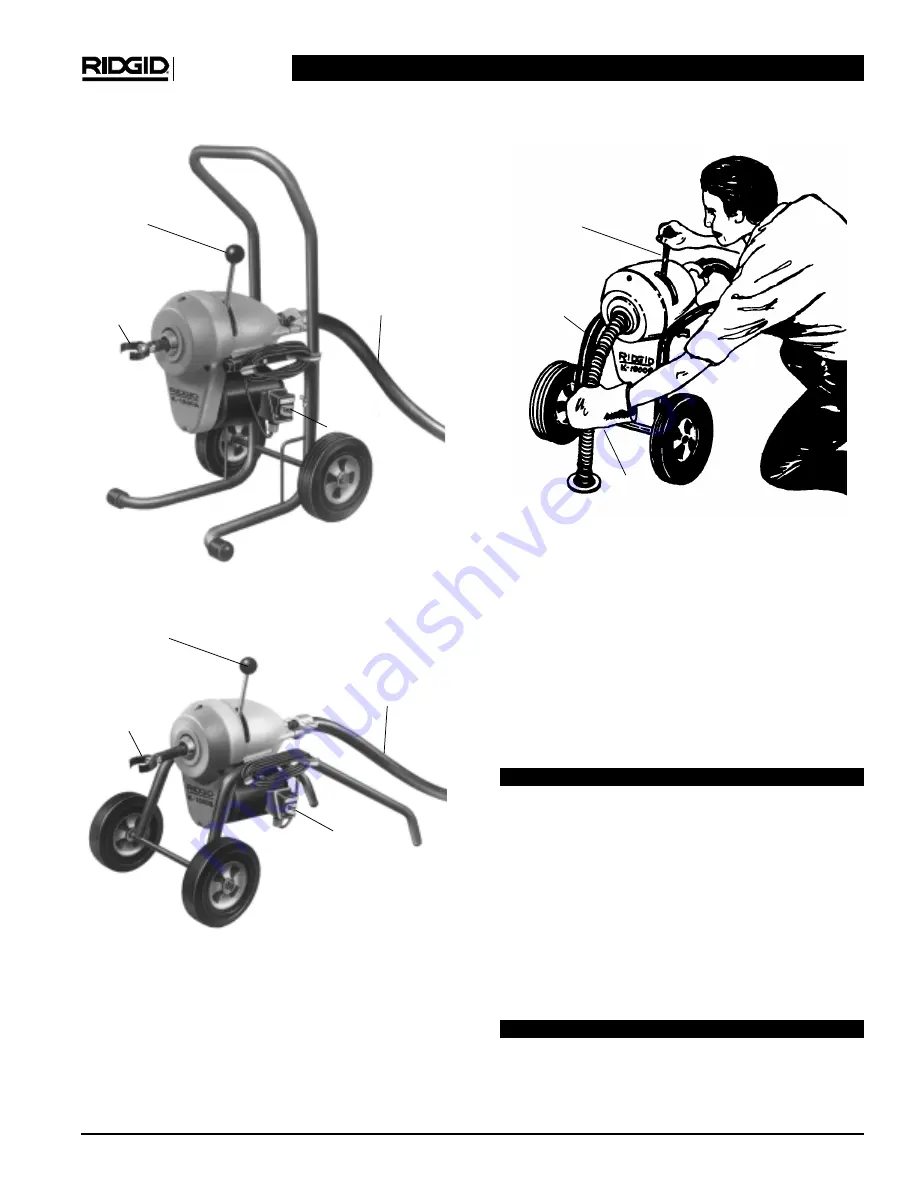

Figure 5 – K-75A and K-1500A Drain Cleaning Machines

Figure 6 – K-75B, K-1500B and K-1500SP Drain Cleaning

Machines

5. With mittened hand, push down on top of loop and pull

clutch handle downward with a definite snap (Figure

7). The tool will easily pass through trap.

Figure 7 – Operating Drain Cleaning Machine

NOTE! A slow or gradual engaging of clutch results in a

weak grip of clutch driver jaws and causes exces-

sive wear. The clutch is instant acting and returning

clutch handle to its original position frees cable in-

stantly. There is no overrun to loop or break cable.

6. As soon as excess cable has gone into line, release

clutch handle and pull 12

″

of cable out of machine with

left hand, engage clutch and allow cable to feed into

drain.

7. Release clutch and repeat process until obstruction or

cable end is reached. Add additional cable(s) as

needed one at a time. (Figure 7)

CAUTION

When obstruction is reached, advance cable inches

at a time. At this point, progress depends upon

sharpness of tool and nature of obstruction.

8. If tool gets hung up in obstruction, release clutch

handle and let motor come to a complete stop before

reversing.

9. Place FOR/OFF/REV Switch in REV (reverse) po-

sition.

10. Engage clutch handle only until tool is free of ob-

struction. Release clutch handle immediately.

CAUTION

Operating machine in REV (reverse) position can

cause cable damage and is used only to back tool

out of an obstruction.

Clutch

Handle

Tool

FOR/OFF/REV

Switch

Guide

Hose

Clutch

Handle

Guide

Hose

FOR/OFF/REV

Switch

Tool

Clutch

Handle

Cable

Mitten