9. Turn the ON/OFF switch to the OFF position.

10. Remove tubing from the machine. Raise the cutter

handle to its maximum height.

Cleaning/Deburring O.D. of Tube

1. Turn the ON/OFF switch to the ON position.

2. Place the end of the tube on the rest plate. Lengths of

tubing longer than four feet should be supported by

pipe stands.

Pipe supports are needed to maintain

control of the workpiece.

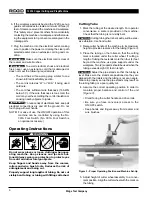

3. Press tube gently against the brush and rotate slow-

ly until surface is bright (Figure 6).

Keep hands away from rotating parts.

4. Remove external burrs by rotating tube against debur-

ring cutter (Figure 7). This action also bevels the

end of tube for easier insertion into the fitting.

Figure 6 – Cleaning O.D. of Tube

Figure 7 – Deburring O.D. of Tube

5. Turn ON/OFF switch to the OFF position.

Ridge Tool Company

7

NOTE! To adjust the height of the cutter wheel, push

handle to the right and relocate position pin by

moving handle up or down.

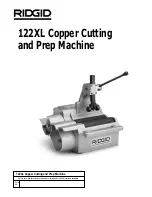

6. Lower the handle until the cutter wheel support rollers

contact the tubing (Figure 4). Turn the ON/OFF switch

to the ON position.

Tubing will rotate. Keep hands away from

ends of tubing that may have burrs or sharp edges.

Figure 4 – Cutter Wheel Support Rollers Contacting

Tubing

7. Apply pressure to the handle slowly and continu-

ously until the tubing is cut. Do not force the cutter

wheel into the workpiece. This will damage and short-

en the life of the cutter wheel.

8. Release pressure from the handle but still have the

cutter wheel support rollers maintain contact with

the tubing (Figure 5). The rollers will hold the tubing so

it will not fall to the ground.

Figure 5 – Cutter Wheel Support Rollers Holding Tubing

After Cut

122XL Copper Cutting and Prep Machine

WARNING

CAUTION

WARNING