Ridge Tool Company

7

Use of roll sets on both carbon and stainless

steel pipe can lead to contamination of the stainless steel

material. This contamination could cause corrosion and

premature pipe failure. To prevent ferrous contamination,

use roll sets dedicated for stainless steel grooving.

Operating the 918-I Roll Groover

WARNING

Do not wear loose clothing when operating a Roll

Groover. Keep sleeves and jackets buttoned. Do

not reach across the machine or pipe.

Do not use this Roll Groover if it has a broken or

missing foot switch. Always wear eye protection to

protect eyes from dirt and other foreign objects.

Keep hands away from grooving rolls. Do not wear

loose fitting gloves when operating groover. Use

pipe stands to support pipe.

When grooving, keep hands away from end of pipe.

Do not reach inside pipe end.

Pipe Preparation

1. Pipe ends must be cut square. Do not use cutting

torch.

2. Pipe out-of-roundness must not exceed the total O.D.

tolerance listed in groove specifications,

Table 1.

NOTE! Determine out-of-roundness by measuring max-

imum and minimum O.D. at 90 degrees apart.

3. All internal or external weld beads, flash or seams

must be ground flush at least 2 inches back from

pipe end.

NOTE! Do not cut flats on gasket seat area.

Pipe/Tubing Length

The following chart lists the minimum length of pipe or tub-

ing to be grooved and the maximum length to be grooved

with one (1) pipe stand.

Pipe Set-Up

1. Pipe or tubing longer than the specified maximum

lengths listed in Chart A must be supported with two

(2) pipe stands. The second pipe support should be lo-

cated

3

/

4

of pipe length from roll groover.

Failure to use two stands may result in the

unit tipping or the pipe falling.

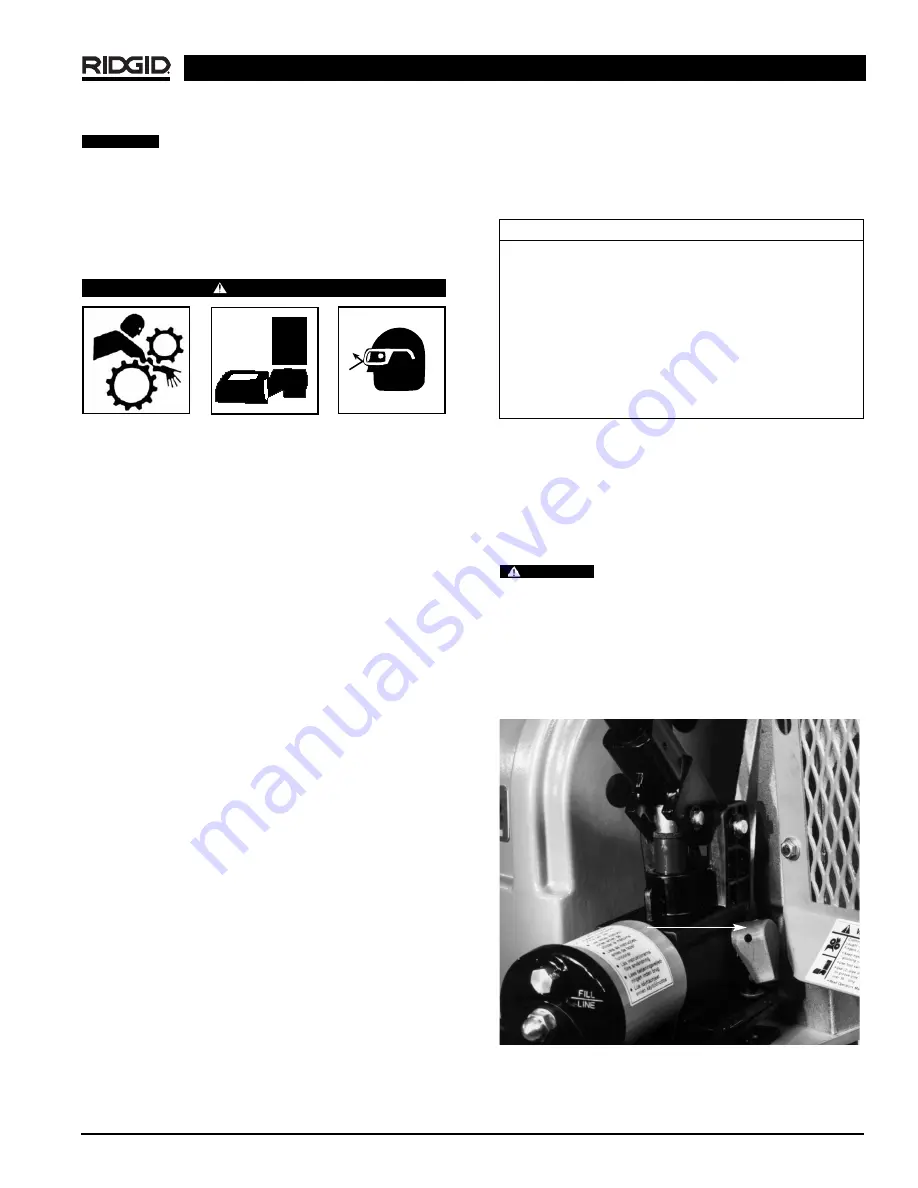

2. Raise upper groove roll housing by placing pump re-

lease lever in RETURN position (away from operator)

(Figure 4).

3. Square pipe and pipe support to roll groover making

sure pipe is flush against drive roll flange

(Figure 5).

Figure 4 – Close-up of Release Lever on 918-I Pump

918-I Heavy Duty Roll Grooving Machine

Groovable Pipe Lengths – Inches

Nom.

Min.

Max.

Nom.

Min.

Max.

Size

Length

Length

Size

Length Length

1

8

36

4

8

36

1

1

/

4

8

36

4

1

/

2

8

32

1

1

/

2

8

36

5

8

32

2

8

36

6 O.D.

10

30

2

1

/

2

8

36

6

10

28

3

8

36

8

10

24

3

1

/

2

8

36

10

10

24

4

8

36

12

10

24

Chart A – Minimum/Maximum Pipe Length

WARNING

CAUTION