17

MAINTENANCE

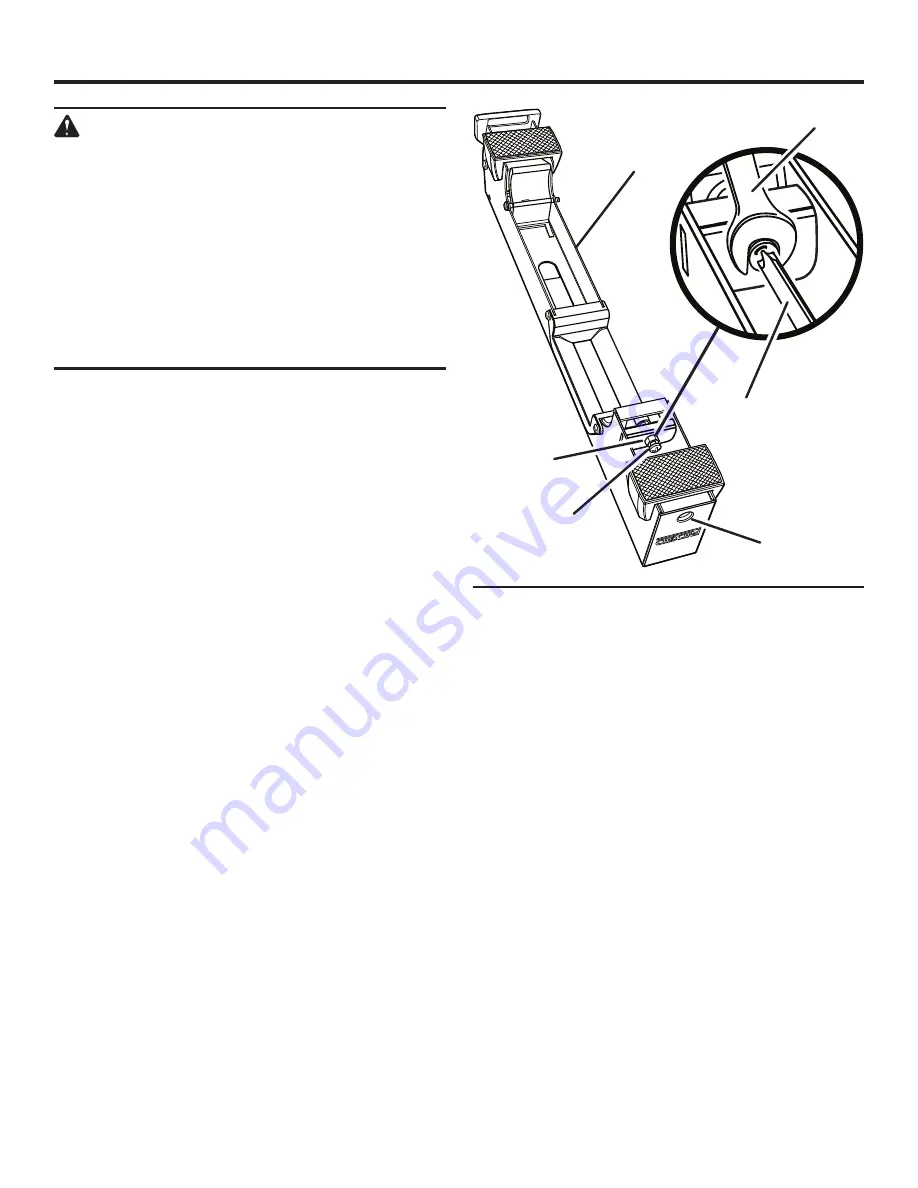

Fig. 23

WARNING:

The saw mounting brackets are designed to fit

snugly over the table edges with locking levers in

the open position. With the locking levers in the

lowered (locked) position, you should not be able

to slide the saw mounting bracket assembly along

the table edges or remove the bracket assembly

from the table edges. If the saw mounting brackets

will not fit over the edges, or if the brackets can

be removed from the edges when the levers are

locked, remove bracket assembly immediately and

adjust bracket adjustment screw. Failure to heed

this warning may result in serious personal injury.

SAW MOUNTING BRACKET ADJUSTMENT

See Figure 23.

If the saw and bracket assembly can slide over the table

edges or be removed from the table edges when the levers

are locked, the bracket adjustment screws need to be

tightened. If the saw and bracket assembly will not fit over

both table edges, the bracket adjustment screw needs to

be loosened.

NOTE:

The saw should be removed from the mounting

brackets before attempting to tighten or loosen the bracket

adjustment screws.

To adjust:

Use a wrench to slightly loosen the nut.

Turn the screw with a phillips screwdriver. Rotate

clockwise if the bracket assembly needs to be tightened

or counterclockwise if the assembly needs to be

loosened.

NOTE:

If locking lever on saw mounting bracket cannot

easily be pushed down into the closed position, the

adjustment screw is too tight. Do not force locking lever

into the closed position. Loosen the adjustment screw.

Install the bracket on the front table edge then lower

bracket to allow the rear clamp of the bracket to seat

fully over the rear table edge.

NOTE:

The mounting bracket should fit snugly over the

table edges when in the open position.

When the correct position is achieved, wrench-tighten

the nut to secure.

Repeat with the second mounting bracket.

To purchase additional saw mounting bracket assemblies

(part no. 900510802), call RIDGID customer service at

1-866-539-1710.

SAW

MOUNTING

BRACKET

SCREWDRIVER

WRENCH

NUT

BRACKET

ADJUSTMENT

SCREW

SCREWDRIVER

ACCESS HOLE

Summary of Contents for AC9944

Page 18: ...18 NOTES ...