Safety Instructions

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROB-

LEMS. To help recognize this informa-

tion, observe the following symbols.

Safety Signal Words

Danger indicates

an imminently haz-

ardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially haz-

ardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates

a potentially haz-

ardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important informa-

tion, that if not followed, may cause dam-

age to equipment.

NOTICE:

!

CAUTION:

!

WARNING:

!

DANGER:

Fr 22

3

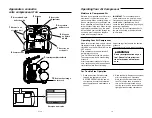

Air compressors are utilized in a variety

of air system applications. Because air

compressors and other components

(material pump, spray gun, filters,

lubrications, hoses, etc.) used make up a

high pressure pumping system, the

following safety precautions should be

observed at all times. Only persons well

acquainted with these rules of safe

operation should be allowed to use the

air compressor.

1. Read instruction manuals for each

component carefully, before

attempting to assemble, disassemble

or operate your particular system.

2. Wear safety glasses (meeting ANSI

Z87.1 or in Canada CSA Z94.3-99)

and use hearing protection when

operating the pump or unit. Everyday

glasses are not safety glasses.

3. Do not exceed pressure rating of any

component in system.

4. Protect material lines and air lines

from damage or puncture. Keep hose

and power cable away from sharp

objects, chemical spills, oil, solvents,

and wet floors.

5. Never point a spray gun at oneself or

any other person. Accidental

discharge may result in serious injury.

6. Check hoses for weak or worn

condition, before each use, making

certain all connections are secure; do

not use if deficiency is found. Notify

an authorized service facility for

examination or repair.

7. Release all pressures within system

slowly; dust and debris may be harmful.

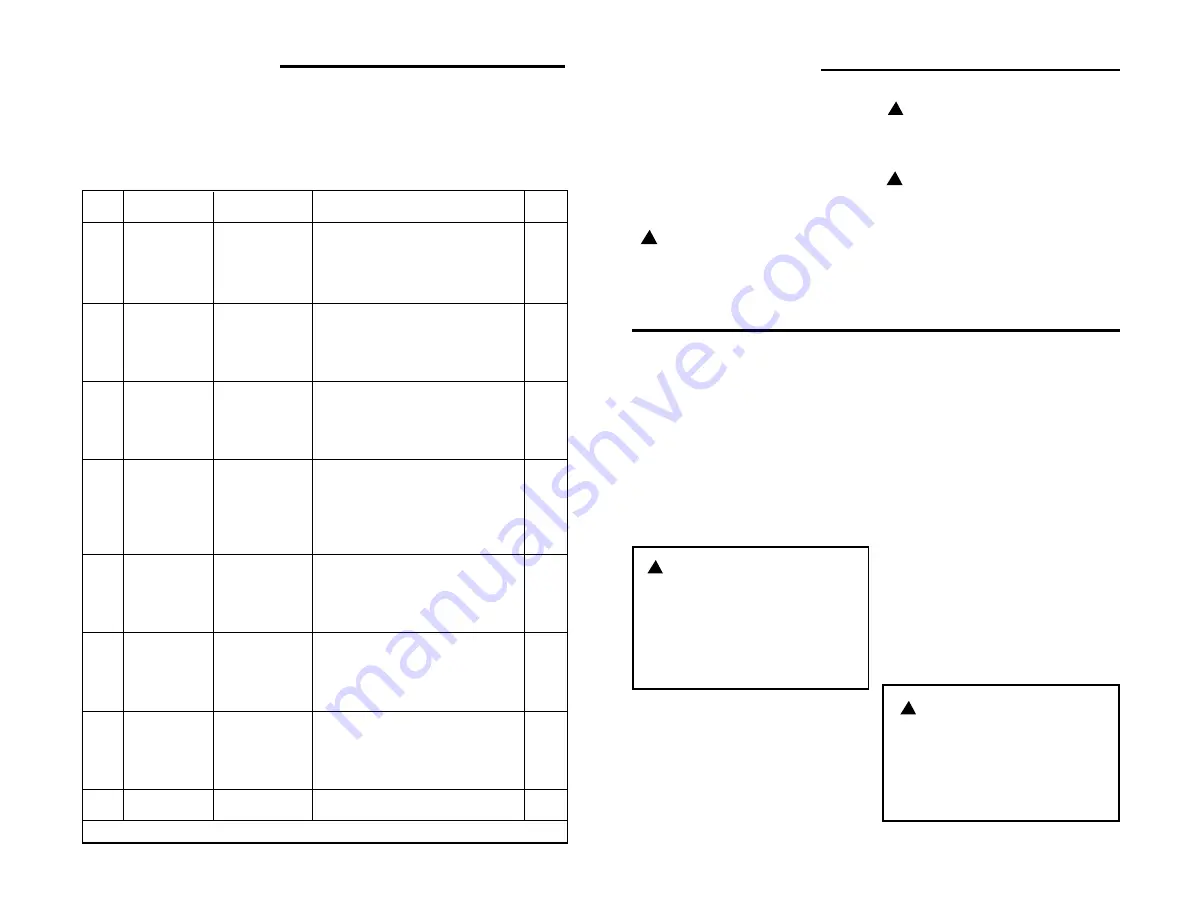

Before Using the Air Compressor

All electrical work should be

done by a qualified (licensed or

certified) electrician. On a prop-

erly wired circuit, the black

wires supply a voltage poten-

tial even when the unit is off.

!

WARNING:

Disconnect power and depres-

surize system before servicing

air compressor! (Turn pressure

regulator knob fully clockwise

after shutting off compressor.)

!

WARNING:

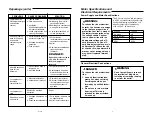

Pièces de rechange

Pour les pièces de rechange, appeler le 1-800-4-RIDGID

S’il vous plaît fournir l’information suivante:

-Numéro du modèle

-Numéro de série (si applicable)

-Description de la pièce et son numéro sur la liste de pièces

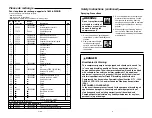

No de

No de

Numéro

clé

catalogue

de pièce

Description

Qte

1

--

--

Corps du moteur

1

2

--

--

Bouchon

1

3

--

--

Ventilateur

1

4

†

†

Boulon (M4 X 21)

2

5

†

†

Rondelle (M4)

2

6

†

†

Écrou (M4)

2

7

†

†

Vis (M5 x 6)

3

8

--

--

Garde-ventilateur

1

9

†

†

Vis (M8 x 20)

4

10

†

†

Rondelle

4

11

--

--

Tampon isolateur

4

12

†

†

Écrou (M8)

4

13

†

†

Vis hexagonale creuse (M6 x 80)

4

14

†

†

Rondelle (M6)

4

15

28343

FP250018AV

Tête du cylindre

1

16

28348

FP250019AV

Valve de démarrage à froid

1

17

Joint d’étanchéité de couvercle de

cylindre

1

18

Goupille de valve

2

19

Plaque de contact

1

20

Plaque de cylindre

1

21

Plaque de valve

1

22

Joint d’étanchéité de cylindre

1

23

Cylindre

1

24

Support d’anneau de piston

1

25

Anneau de piston

1

26

Vis (M4 x 8)

1

27

Rondelle (M4)

1

28

Valve

1

29

Tige de piston

1

30

Rondelle (M4)

1

31

Vis (M4 x 20)

1

32

Excentrique

1

33

Boulon

1

34

Roulement à billes

1

35

Garniture

1

36

Couvercle de protection

1

37

†

†

Vis (M5 x 32)

3

Suite à la page suivante