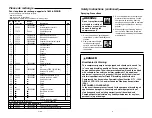

Entretien (suite)

Fr 16

1. Entreposer les tuyaux et le compresseur

dans un endroit frais et sec.

2. Le réservoir doit être purgé d’humidité.

3. Le tuyau doit être débranché et

accroché avec les bouts ouverts face

en bas afin de faire écouler toute

l’humidité.

Entreposage

Tous les

Opération

Quotidien

Hebdomadaire

3 mois

Purger le réservoir

Vérifier la soupape de sûreté

Souffler la saleté de l’intérieur du moteur

Horaire d’entretien

9

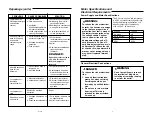

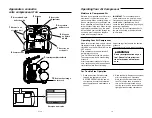

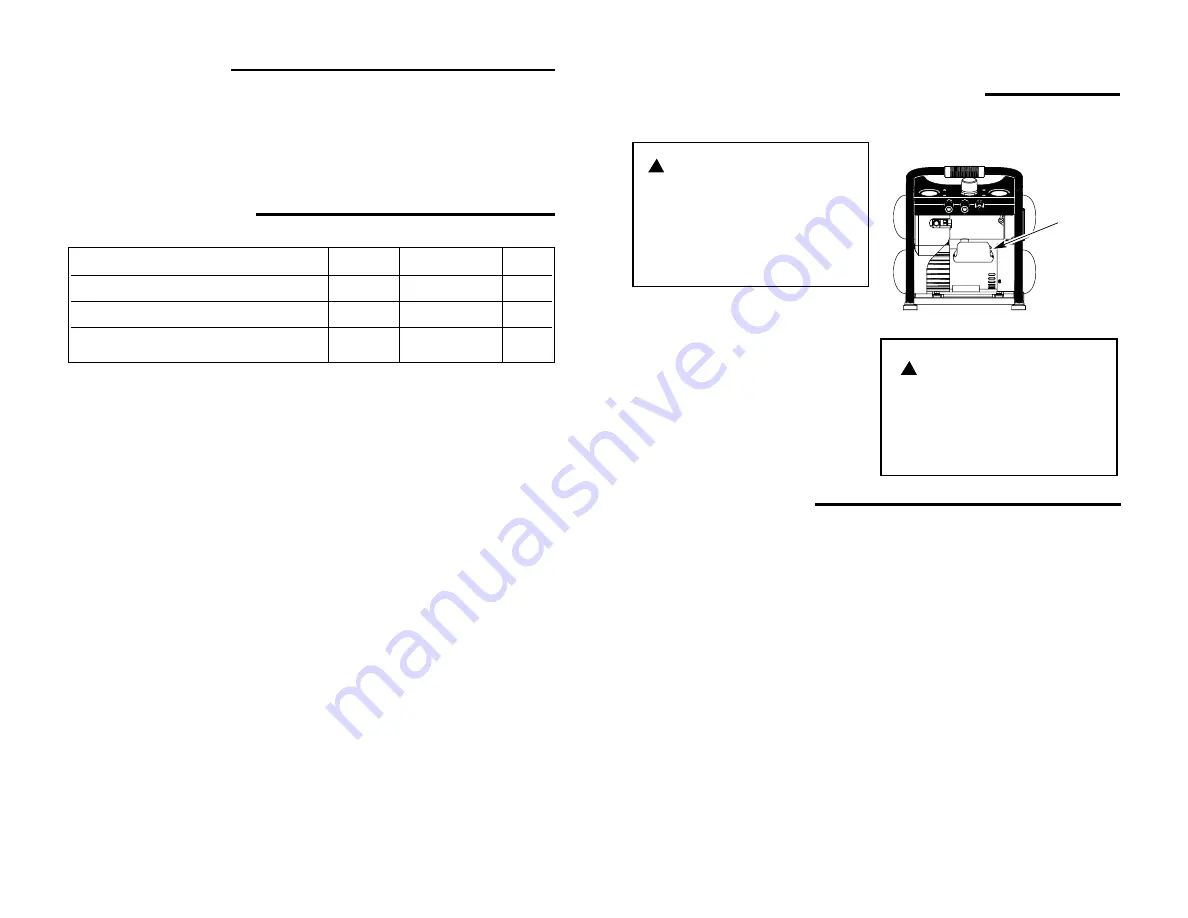

Thermal Overload Protector

If overload protector shuts motor OFF fre-

quently, look for the following causes.

1. Low voltage.

2. Clogged air filter.

3. Lack of proper ventilation.

See Troubleshooting Chart for corrective

action.

This compressor is equipped

with a manual reset overload

protector which will shut off

motor if it becomes over-

loaded.

!

CAUTION:

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output is

measured by a pressure gauge on the com-

pressor

SCFM (Standard Cubic Feet per Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume deliv-

ered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The com-

bination of these figures determines what

size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Volts or Voltage

A measurement of the force of an electrical

current.

Amps or Amperage

A measure of the electrical force minus the

resistance on an electrical line. Ridgid air

compressors require 15 amps for operation.

Be sure the compressor will operate on an

electrical line with the proper amps. If other

appliances operate on the same line, they

will reduce the available amps. If the

amperage is not adequate, the result will be

blown fuses or tripped circuits.

Glossary of Terms

Motor Specifications and

Electrical Requirements (continued)

If the overload protector is actu-

ated, the motor must be allowed

to cool down for 30 minutes

before manual resetting.

!

CAUTION:

Thermal

overload

protector