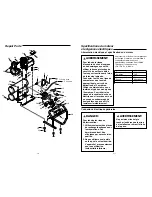

Pièces de rechange

No.

No de

Numéro

Ref.

catalogue

de pièce

Description

Qte

1

—

WL373001AV

* Montage pompe/moteur

1

2

20448 ST085700AV

Filtre

1

3

20488 ST085701AV

* Cartouche filtrante

1

4

17713 ST158000AV

Embase de bouton

4

5

17718 WL003202AV

Douille en caouct chouc (Arrière)

2

6

17723 WL003203AV

Douille en caouct chouc [avant]

2

7

17728 CV222203AJ

* Clapet

1

8

— WL029600AV

Tuyau d’echappement

(écrous et viroles inclus)

1

9

—

Écrou

1

10

—

Virole

1

11

—

ST188800AV

Tube flexible - déchargeur

1

12

17753 ST209800AV

Vis de décharge de tension

1

13

17758 CW209600AV

Décharge de tension

1

14

17763 EC012600AV Cordon

1

15

17773

GA016709AV

* Jauge du réservoir

1

16

17783

N/D

Vis de 1/4 po - 20 x 1/2 po

4

17

17793

WL024501AV

* Ensemble rég. (inclut 15, 25 et 28)

1

18

17798 V-215106AV

Soupape de sûreté 1138 kPa

1

19

17808 ST185600AV

* Prise

1

20

17813 WL025900AV

Arceau de sécurité

1

21

17838 WL025800AV

Fixation de panneau de contrôle

1

22

17848 ST073276AV

Vis de pied

4

23

17853 ST158300AV

Pare chocs en caoutchouc mouté

4

24

— ST170100AV

Tuyau

de nylon - collecteur

1

25

17863 ST074415AV Vis autotaraudeuse de 1/4 po - 20 x 1/2 po

4

26

— AT170000AV

Raccord de compression de 90

°

2

27

17873 HF203300AV

* Raccord

2

28

17878

GA016705AV

* Jauge de sortie

1

29

17883 CW210000AV Déchargeur

1

30

17888 ST022500AV Bouchon

1

31

17898 HF002401AV Raccord

1

32

17903 CW211700AV

* Couvercle de manostat

1

33

17908

CW211300AJ

* Manostat

1

34

17913 D-1403

* Robinet de vidange du réservoir

1

35

17918 ST073612AV

Bouchon

1

36

17923

AR052700OE

Double réservoir 15,14 L

1

37

17928 ST129301AV

Vis de couvercle de protection

1

38

17933 ST129302AV

Vis de couvercle de protection

2

39

17938 WL012406AV Couvercle

1

40

17943 ST072224AV Raccord

d’échappement

1

* Considérés des articles d’usure normale

N/D = articles de quincaillerie standard

Fr 21

Pour les pièces de rechange, appeler le 1-800-4-RIDGID

S’il vous plaît fournir l’information suivante:

-Numéro du modèle

-Numéro de série (si applicable)

-Description de la pièce et son numéro sur la liste de pièces

codes, as well as the National

Electrical Code (NEC) and the

Occupational Safety and Health Act

(OSHA).

9. Wiring and fuses should follow electri-

cal codes, current capacity, and be

properly grounded.

10. Electric motors must be securely and

adequately grounded. See grounding

instructions and extension cord infor-

mation in this manual.

11. Always disconnect power source

before working on or near a motor, or

its connected load. If power discon-

nect point is out-of-sight, lock it in the

open position and tag to prevent

unexpected application of power.

12. Guard all moving parts; keep visitors

away. Never allow children in work

area.

13. Use only a properly grounded outlet

that will accept a three pronged plug,

and wear shoes to prevent shock

hazards.

14. Be careful when touching exterior of

operating motor; it may be hot

enough to cause injury.

15. Protect power cable from coming in

contact with sharp objects.

16. Clean electrical or electronic equip-

ment with an approved cleaning

agent, such as dry, nonflammable

cleaning solvent.

17. To avoid spontaneous combustion,

discard waste rags into approved

metal waste cans.

18. Never store flammable liquids or

gases in vicinity of compressor.

19. When spraying with solvent of toxic

chemicals, follow instructions provid-

ed by the chemical manufacturer.

20. Spray in a well ventilated area, to

keep fumes from collecting and caus-

ing health and fire hazards.

21. Do not spray in vicinity of open

flames or other places where a spark

can cause ignition. Do not smoke

when spraying paint, insecticides, or

other flammable substances.

22. Use a respirator when spraying.

23. NEVER reset safety valve or pressure

switch. Keep safety valve free from

paint and other accumulations. This

provides safety against over pressure.

24. Do regular maintenance; keep all

nuts, bolts, and screws tight, to be

sure equipment is in safe working

condition .

25. Keep cleaning rags and other flam-

mable waste materials in a tightly

closed metal container and dispose of

later in the proper fashion.

26. Drain tanks of moisture after each

day’s use. If unit will not be used for a

while, it is best to leave drain cock

open until such time as it is to be

used. This will allow moisture to com-

pletely drain out and help prevent cor-

rosion of inside of tank.

27. Inspect tank yearly for rust, pin holes

or any other imperfections that could

cause it to become unsafe. NEVER

weld or drill holes in air tank.

Safety Instructions (continued)

4