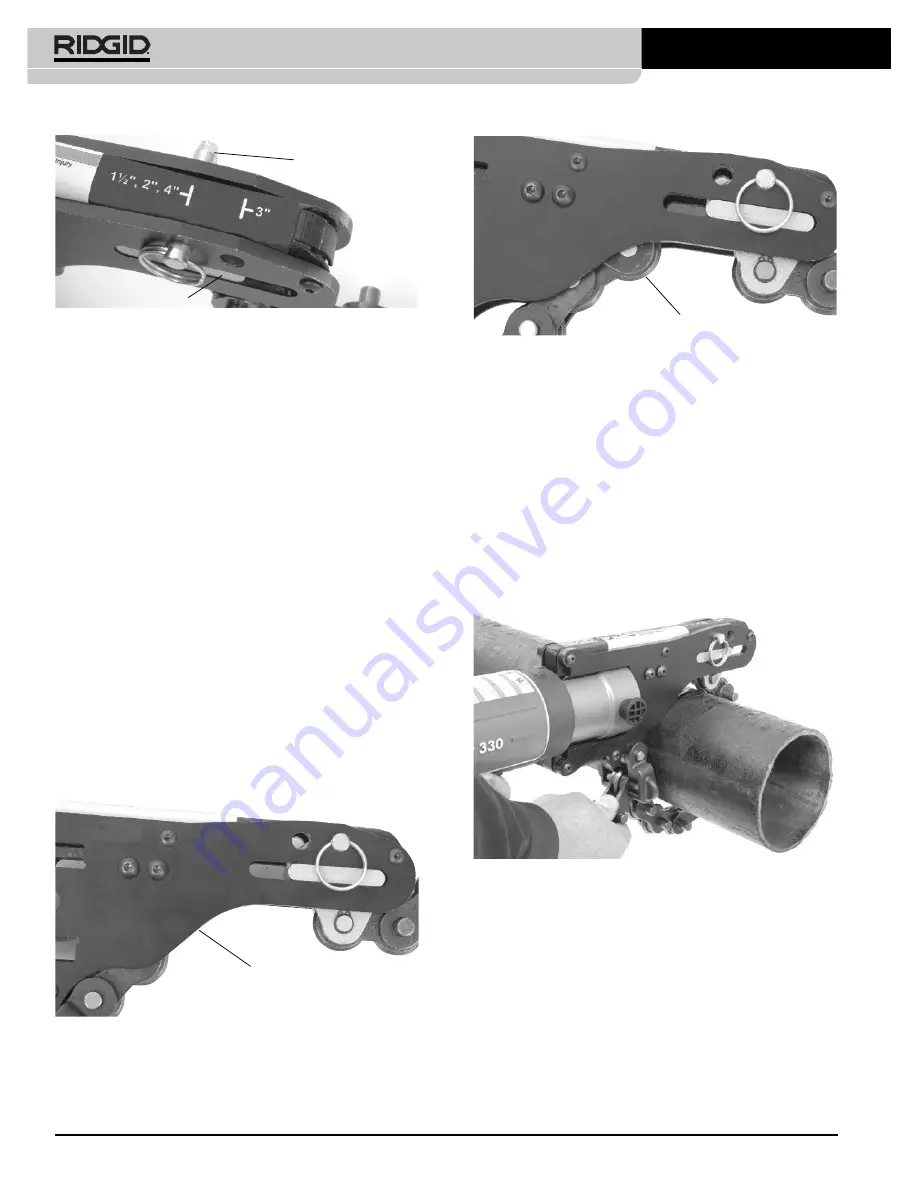

Figure 3B – Not Fully Retracted

10. Choose a spot from which to operate the cutter.

Keep in mind that when the pipe is cut, parts of it may

be thrown. Make sure that the area is clear of all

personnel or any objects that could be struck by

pipe. Be aware that when the pipe is cut the soil

pipe cutter and pipe could drop or fall.

11. Wrap the Press Snap cutter chain snugly around

the pipe at the point to be cut and place the nearest

chain pin into the chain hooks. Once the appropriate

pin for a given size pipe has been determined, mark-

ing the pin (such as with paint) can save time setting

up subsequent cuts of the same size.

Figure 4 – Wrapping Chain Around Pipe

12. Verify that the chain is square to the pipe at the

desired location. Keep fingers and hands away from

the chain and other moving parts to avoid crushing

injuries. Depress and hold the press tool switch until

the cut is complete.

The cutting cycle takes between 4-8 seconds depend-

ing on the press tool. Once the chain tightens around

the pipe, the press tool will lock on and automatical-

ly complete the cut. Releasing the press tool switch

will not stop the once the tool has locked on.

Figure 2 – Size Adjustment

7. Insert the Press Snap cutter into the press tool and

power as directed in the press tool operator’s manual.

8. If using the Press Snap cutter with a 320-E Press

Tool, the tool needs to be calibrated.

• Depress ON/OFF button on 320-E display panel

one time to turn tool ON. All three LED’s will blink

once and the tool will beep once. Then the green

LED on the display should be blinking to indicate

that tool needs to be calibrated.

• With no soil pipe in the cutter, depress the press tool

switch and complete one tool cycle. The green

LED on the 320-E display panel will continue to

glow solid indicating proper calibration. The 320-E

is now ready for soil pipe cutting. If the 320-E is shut

off, the 320-E mounting pin retracted or the tool

alarms, this process will need to be repeated.

9. Confirm that the Press Snap cutter ram is fully retract-

ed. If the cutter wheel mounted to the ram is behind

the sideplate, the ram is fully retracted. If the ram cut-

ter wheel is visible past the sideplate, it needs to be

fully retracted by running one complete tool cycle. If

the ram is not fully retracted, the tool may not cut the

pipe.

(See Figures 3A and 3B).

Figure 3A – Ram Fully Retracted

4

Press Snap™ Soil Pipe Cutter

Clevis Pin

Adjustment Block

Cutter Wheel Visible

Cutter Wheel

Behind Side Plate

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com