18

MAINTENANCE

NOTE:

Some commercial air line drying liquids are harmful

to “O” rings and seals. Do not use these low temperature

air dryers without checking compatibility.

�

AIR SUPPLY-PRESSURE AND VOLUME

Air volume is as important as air pressure. The air volume

supplied to the tool may be inadequate because of undersize

fittings and hoses, or from the effects of dirt and water in the

system. Restricted air flow will prevent the tool from receiving

an adequate volume of air, even though the pressure read-

ing is high. The results will be a slow operation, misfeeds or

reduced driving power. Before evaluating tool problems for

these symptoms, trace the air supply from the tool to the

supply source for restrictive connectors, low points contain-

ing water, and anything else that would prevent full volume

flow of air to the tool.

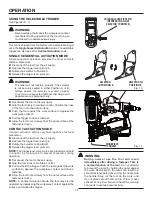

REPLACING THE NOSEPIECE

See Figure 15.

The nosepiece with carbide inserts may be replaced when

the inserts are worn.

Disconnect the tool from the air supply.

Loosen the nose screws with the hex key provided.

Remove the screws.

Remove the old nosepiece.

Install the new nosepiece. Align the holes in the nosepiece

with the holes in the nose of the tool.

Replace the nose screws and tighten with the hex key.

Do not overtighten.

WARNING:

When servicing use only identical RIDGID

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear safety goggles or safety glasses with

side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a

dust mask.

WARNING:

Disconnect the tool from the air supply before

performing maintenance. Failure to do so could

result in serious personal injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may

result in serious personal injury.

LUBRICATION

�Frequent, but not excessive, lubrication is required for

best performance. Oil for pneumatic fastening tools added

through the air line connection will lubricate the internal parts.

Do not use detergent oil or additives as these lubricants will

cause accelerated wear to the seals and bumpers in the

tool, resulting in poor tool performance and frequent tool

maintenance.

COLD WEATHER OPERATION

For cold weather operation near and below freezing, the

moisture in the air line may freeze and prevent tool operation.

We recommend the use of air tool lubricant or permanent

antifreeze (ethylene glycol) as a cold weather lubricant.

CAUTION:

Do not store tools in a cold weather environment

to prevent frost or ice formation on the tools’

operating valves and mechanisms that could

cause tool failure.

SCREWS

NOSEPIECE

NOSE OF TOOL

Fig. 15