10

®

�

®

OPERATION

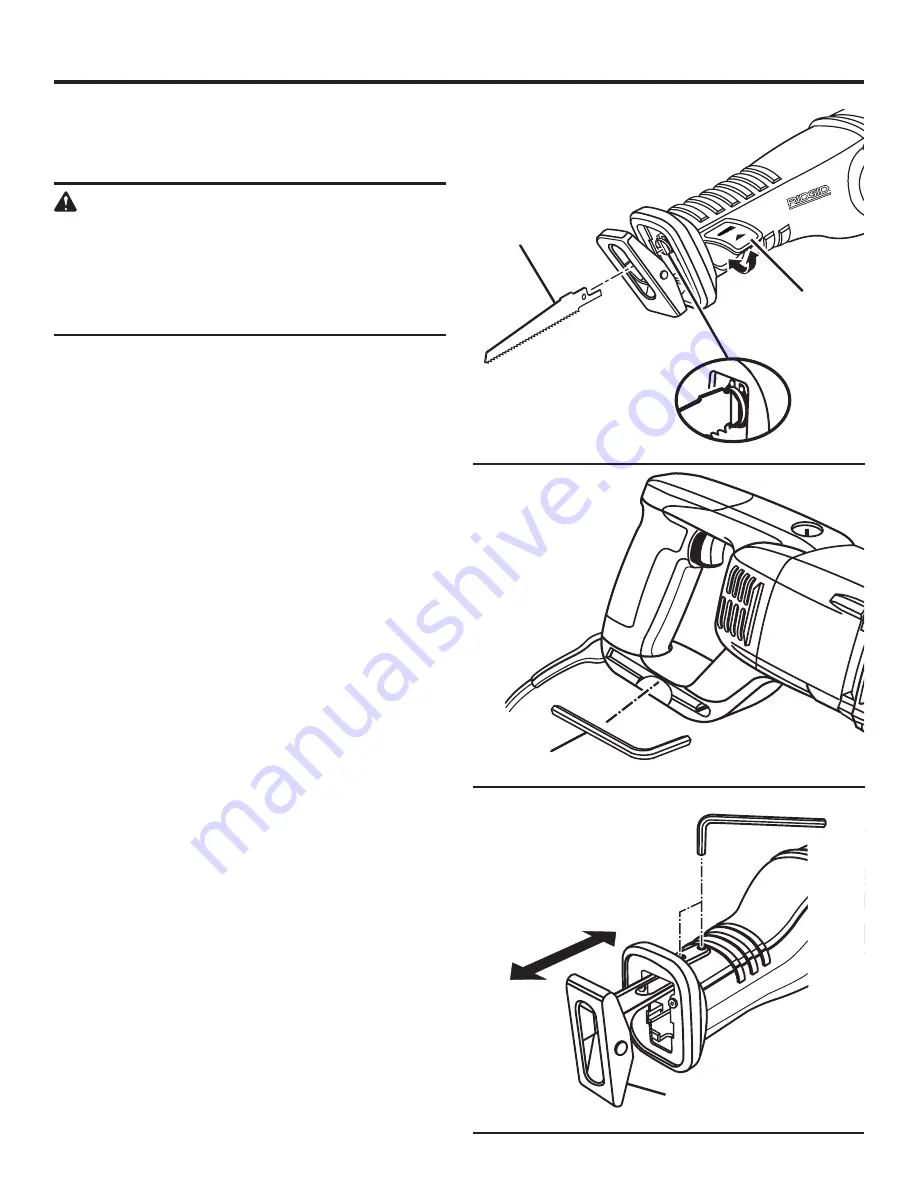

TO INSTALL BLADE

See Figure 2.

n

Unplug the saw.

WARNING:

The tool should never be connected to a power

supply when you are assembling parts, making

adjustments, cleaning, performing maintenance, or

when the tool is not in use. Disconnecting the tool

will prevent accidental starting that could cause

serious injury.

n

Lift blade clamp lock/release lever located on side of

saw.

n

Insert saw blade between blade clamp and saw bar.

NOTE:

Blade can be installed with teeth facing either up

or down.

n

Lower blade clamp lever to lock position.

BASE ASSEMBLY

The base assembly of the reciprocating saw pivots up and

down in both directions. The base is adjustable, allowing the

use of the blade teeth at different positions on the blade.

TO CHANGE POSITIONS OF THE BASE

ASSEMBLY

See Figures 3 - 4.

n

Unplug the saw.

n

Remove hex key from the hex key storage in the

handle.

n

Loosen the screws in the gear frame with the hex key.

n

Reposition base assembly.

n

Retighten screws securely.

Do not

overtighten screws

or use an aid with hex key.

n

Remove hex key and replace in storage.

Fig. 2

Fig. 3

Fig. 4

BLADE

�

�

HEX KEY

BASE ASSEMBLY

BLADE CLAMP

LEVER

Summary of Contents for R3001

Page 14: ...14 NOTES ...