Inspection/Maintenance

1. Daily before use, clean equipment, including handles to aid

inspection and improve control. Clean pivoted blade teeth.

2. Inspect the cutter for:

• Proper assembly and completeness.

• Binding, wear or damage. Inspect the blade profile for

damage.

• Presence and readability of markings and warnings.

If any problems are found, do not use until corrected.

3. Lubricate pivot point with a light lubricating oil. Wipe off any

excess oil.

Set Up and Operation

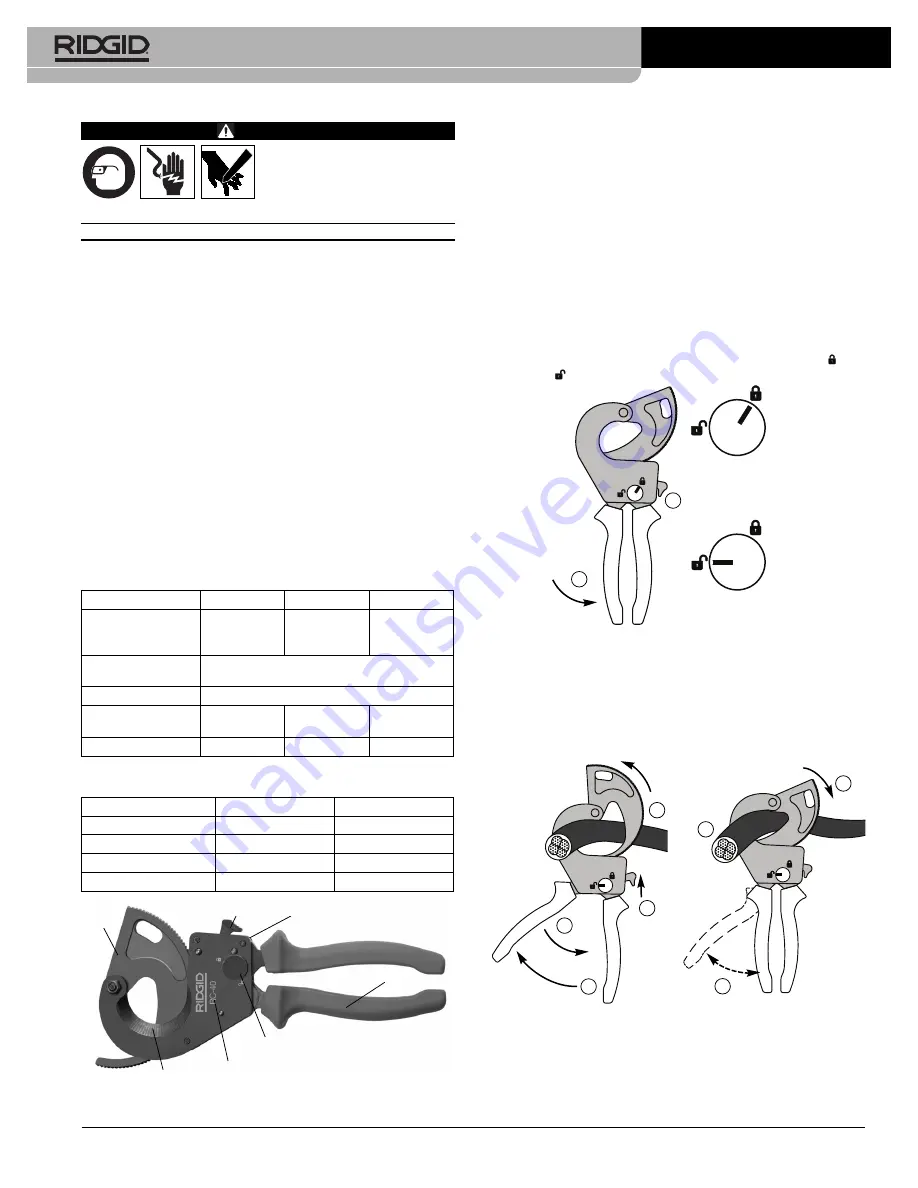

Locking Handles

For storage the handles can be locked closed. Hold the handles

together (1) and move the lock knob to the locked ( ) or

unlocked ( ) position as desired (2).

Figure 2 – Cutter Lock/Unlock

Opening Cutter

Cutter Empty – Either push the pivoted blade through or press the

pawl release to allow the blade to be retracted.

When Cutting - hold the handles together (1) and press the pawl re -

lease (2). Continue pressing the pawl release and open the handles

(3) so that the pawl disengag es from the pivoted blade teeth.

Retract the pivoted blade (4).

Cutting

1. Insert appropriate cable between the blades.

2. Squarely line up the cutting edges with the cut location.

Push the pivoted blade through the cutter into contact with the

cable.

WARNING

Read these instructions and

the warnings for all equip-

ment being used before op -

er ating this tool to reduce

the risk of serious personal injury.

SAVE THESE INSTRUCTIONS!

•

Use personal protective equipment.

Always wear eye pro-

tection to reduce the risk of eye injury.

•

Keep your fingers and hands away from the blades.

Fingers can be cut.

•

Do NOT use on or near energized conductors. These

tools are not insulated.

Use of tools near energized conduc-

tors may lead to electrical shock, causing severe injury or

death.

•

Do not use handle extensions to activate the tool.

Handle

extensions can slip and cause serious injury. Extended han-

dles can overload the tool and cause tool failure and/or seri-

ous personal injury.

If you have any question concerning this RIDGID

®

product:

– Contact your local RIDGID distributor.

– Visit RIDGID.com to find your local RIDGID contact point.

– Contact Ridge Tool Technical Service Department at rtctech-

services@emerson.com, or in the U.S. and Canada call

(800) 519-3456.

Description and Specifications

The RIDGID

®

RC-40, RC-55 and RC-70 Ratchet Cable Cutters are

designed to cut copper and aluminum cables as listed in the

below table. Do not use on ACSR or steel cables.

The RIDGID

®

RC-336 and RC-556 Ratchet Cable Cutters are

designed to cut ACSR cable. Do not use on steel cables.

Figure 1 – Ratchet Cutters (Model RC-40 Shown)

Ratchet Cable Cutters Instructions

999-995-077.10

REV. C

Printed 10/17

EC43120

©2015, 2017 RIDGID, Inc.

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co. or RIDGID, Inc. in the U.S. and other countries.

All other trademarks belong to their respective holders.

MODEL

RC-40

RC-55

RC-70

Max. Cable Diameter

Cu: 600 MCM

Cu: 750 MCM Cu: 1000 MCM

(w/Insulation)

Al: 750 MCM

Al: 1000 MCM Al: 1000 MCM

1.5" (40 mm)

2" (55 mm)

2.75" (70 mm)

Cable Type

Class 2 Stranded Conductor and Class 5

Flexible Conductor to DIN VDE 57295

Conductor Material

Copper and Aluminum

Length in (mm)

9.4"

12.2"

21.7"

(240 mm)

(310 mm)

(550 mm)

Weight lb (kg)

1.5 lb (0,7 kg) 3.3 lb (1,5 kg) 6.4 lb (2,9 kg)

Handles

Warnings

(On Reverse)

Pivoted

Blade

Fixed Blade

Pawl Release

Markings

Locking Knob

LOCK

UNLOCK

2

1

1

3

2

4

1

3

2

Figure 3 – Opening Cutter

when Cutting

Figure 4 – Cutting the Cable

MODEL

RC-336

RC-556

Max. Cable Diameter

336 MCM

556 MCM

Cable Type

ACSR

ACSR

Length in (mm)

9.4" (239 mm)

12.5" (317 mm)

Weight lb (kg)

1.8 lb (0,8 kg)

3.7 lb (1,7 kg)