ENGLISH

Electrical system

Chassis

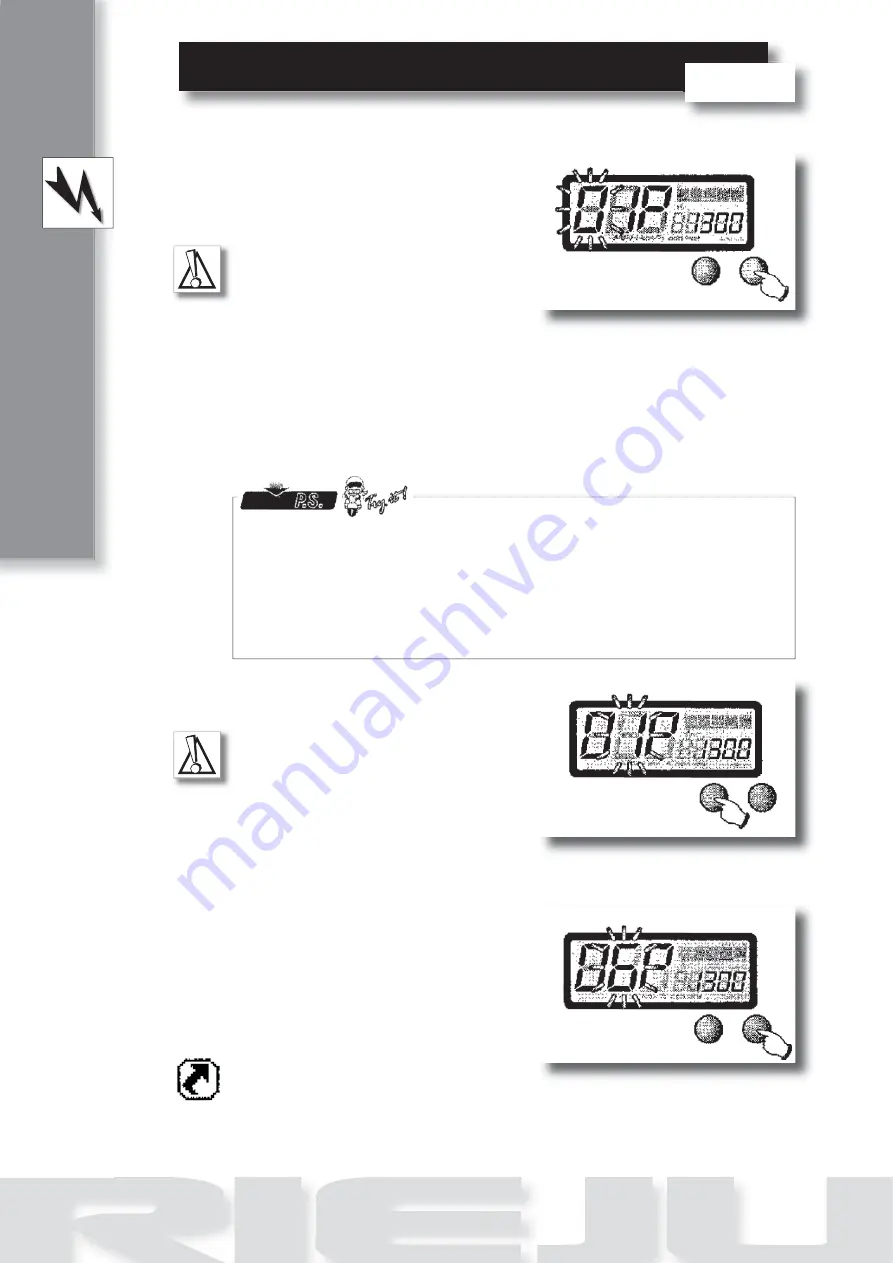

E.g.: the sensor point to be adjusted is 6. Press

the selection button to change to the digit to be

adjusted. E.g.: the original setting is 1 point.

The 0 flashes.

N.B.: Sensor point adjustment interval: 1~60

points. The setting can be changed from left to

right.

N.B.: It is possible to adjust the sensor points

higher than 6 is possible only if the active speed

sensor is being used.

Press the adjustment button to select the set-

ting number.

The sensor points setting number flashes.

Press the selection button to continue adjus-

ting the functions.

E.g.: The adjustment of the sensor points of has

changed from 1 to 6.

N.B.: When this screen is exited, the adjust-

ment defined will begin to be applied.

If adjustment of this function alone is required,

hold down the selection button for three se-

conds to go back to the main screen.

Test it!

The active speed sensor can be fitted next to metal parts such as the brake

disk bolts to detect the distance of the disk and the sprocket holder in order to detect

the frequency of the gear teeth. We recommend using the method of detecting the disk

bolt as a signal for the speed. The more signals there are, the more precise the speed

reading. Please note that the maximum signal that the active speed sensor can read is

60 points per lap.