5895

9

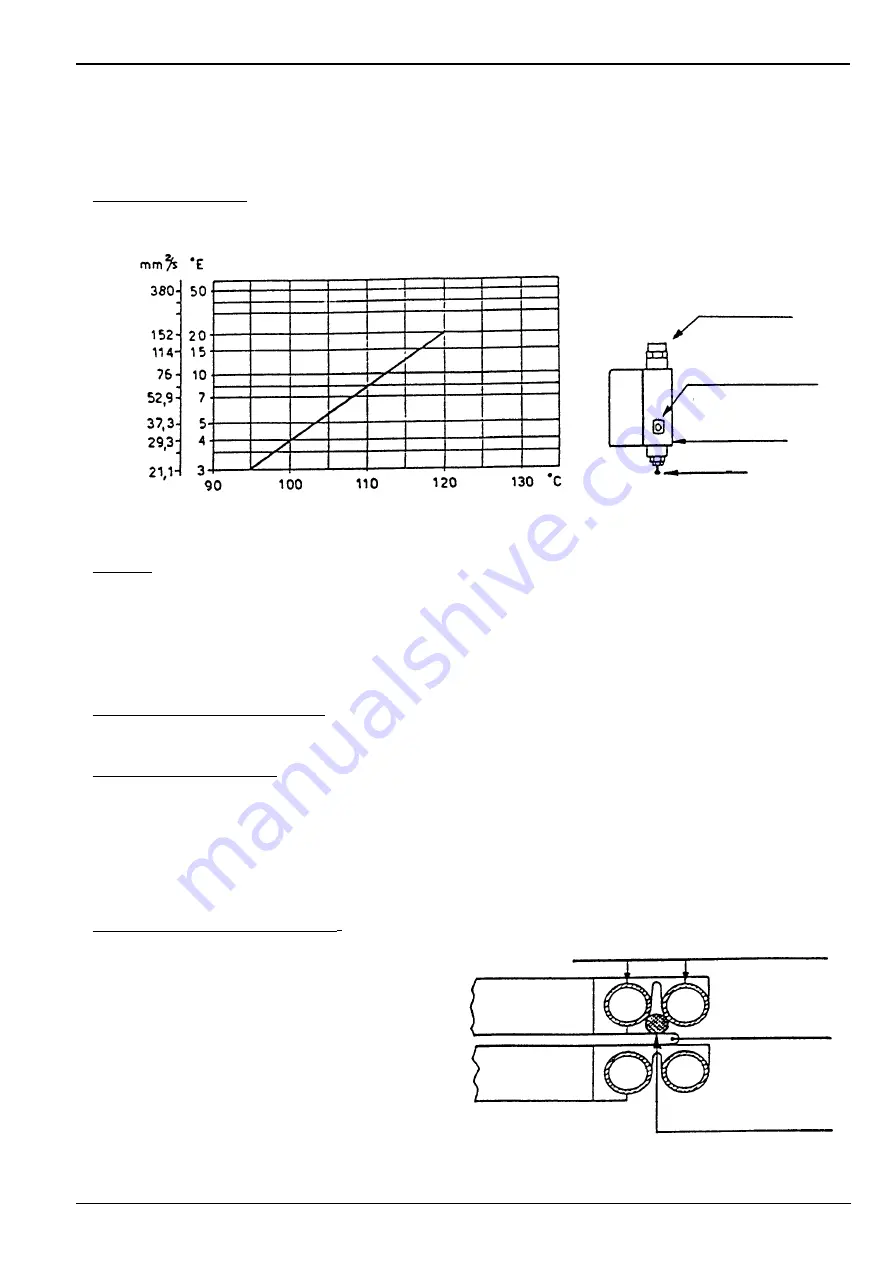

SPRAY TEMPERATURE ADJUSTMENT

Thermostats for: adjustment - maximum value - minimum value

Adjustment thermostat: it prevents the burner start up if the fuel temperature has not reached the required value for

a good spray as indicated in the diagram below.

Example: fuel oil with viscosity of 7 °E at 50 °C is pre-heated at approximately 110 °C.

The thermostat has to be generally set at a value higher than the required one: (120° C indicated on the knob to get

approx. 100° C at the nozzles).

The value read has to be done after some minutes of performance and later the necessary adjustments could be

carried out.

Minimum value contact thermostat: it intervenes by stopping the burner if the fuel temperature decreases under the

value necessary for a good combustion.

Maximum value thermostat: it switches off the resistances when in case of failure of the adjustment thermostat, the

temperature increases inside the pre-heater.

In case of abnormal temperature, make sure of the regular functioning of control thermostat and of the resistance in

contact with the probe of the thermostat.

The thermostat is calibrated by the factory at 180° C.

IMPORTANT NOTICES

Pre-heater thermostats substitution

.

Replace the probe of the new thermostat, after the

loosening of the fixing screws of the plates pack, tak-

ing care of good contact between the probe and the

tubes and the resistance, see drawing.

Similarly for the resistance substitution.

- If during the operation exceptional changes or too

much high temperatures should be detected, verify

the continuity of the resistance, using and ohmme-

ter, contacting the temperature probe (approximate-

ly 35 Ohm).

Sheath for

thermometer

Adjusting knob

of thermostat

Pre-heater

Purge

Spray temperature

Viscosity

a

t 50

° C

Tubes into aluminium plate

Resistance

Thermostat probe

Aluminium

plate