5895

11

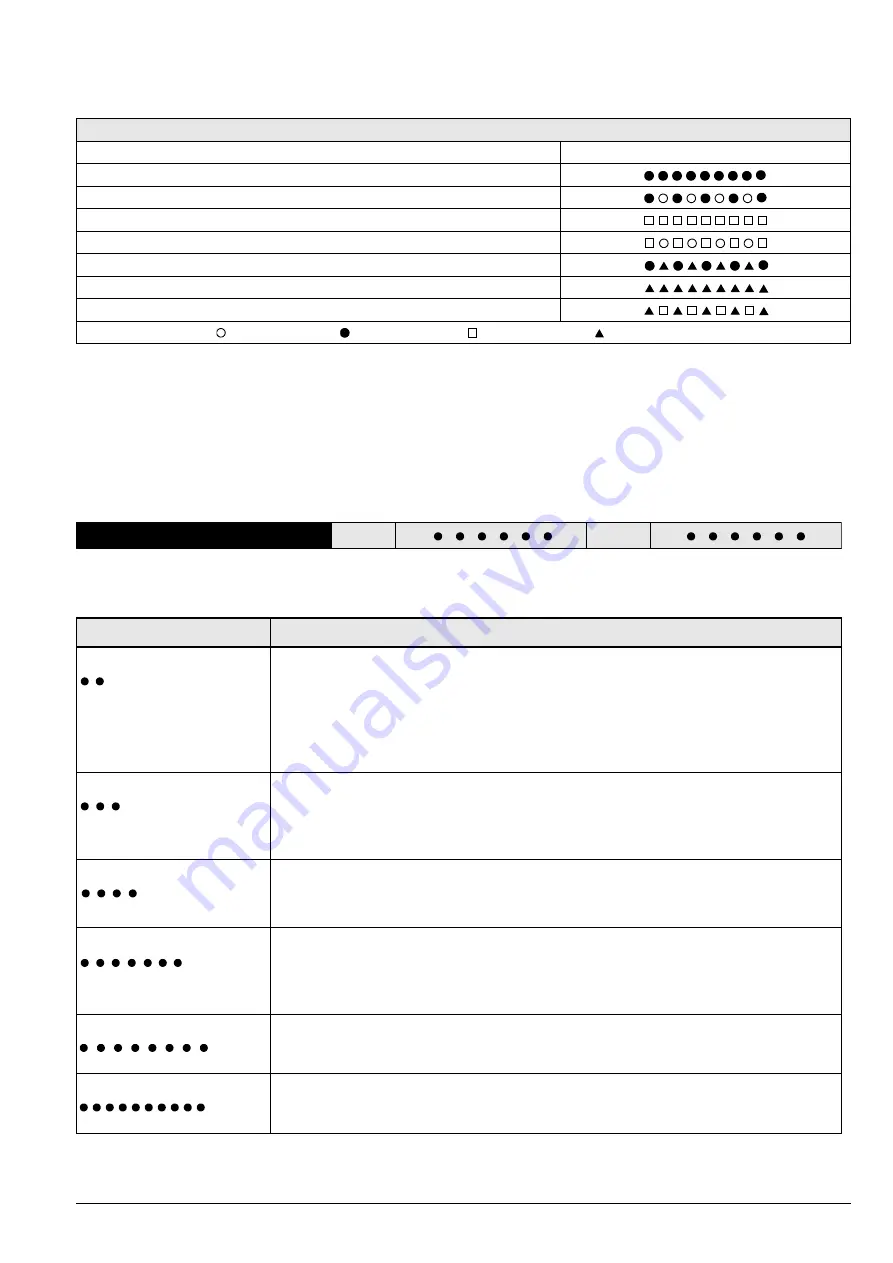

BURNER START-UP CYCLE DIAGNOSTICS

During start-up, indication is according to the followin table:

OPERATING FAULT DIAGNOSTICS

The control box has a self-diagnostic system, which easily allows identifying the operating faults (

RED LED

signal).

ITo use this function, wait at least ten seconds from the safety lock out, and then press the reset button for a minimum of 3 sec-

onds.

After releasing the button, the RED LED starts flashing as shown in the diagram below.

The pulses of the LED constitute a signal spaced by approximately 3 seconds.

The number of pulses will provide the information on the possible faults, according to the table below:

COLOUR CODE TABLE

Sequences

Colour code

Pre-purging

Ignition phase

Operation, flame ok

Operating with weak flame signal

Electrical supply lower than ~ 170V

Lock-out

Extraneous light

Key:

Off

Yellow

Green

Red

SIGNAL

PROBABLE CAUSE

2 flashes

The flame does not stabilise at the end of the safety time:

– faulty photocell;

– faulty or soiled oil valves;

– neutral/phase exchange;

– faulty ignition transformer

– poor burner regulation (insufficient heavy oil).

3 flashes

Min. air pressure switch (if installed) does not close:

– air pressure switch faulty;

– air pressure switch incorrectly regulated;

– max. air pressure switch triggered (if installed).

4 flashes

Min. air pressure switch (if installed) does not open or light in the chamber before firing:

– air pressure switch faulty;

– air pressure switch incorrectly regulated.

7 flashes

Loss of flame during operations:

– poor burner regulation (insufficient heavy oil);

– faulty or soiled oil valves;

– short circuit between photocell and earth.

8 flashes

– Faulty thermostat for oil permissive signal;

– Heating resistances blown.

10 flashes

– Wiring error or internal fault.

RED LED on

wait at least 10 s

Press button

for > 3 s

Signal

Signal

Interval

3 s