40

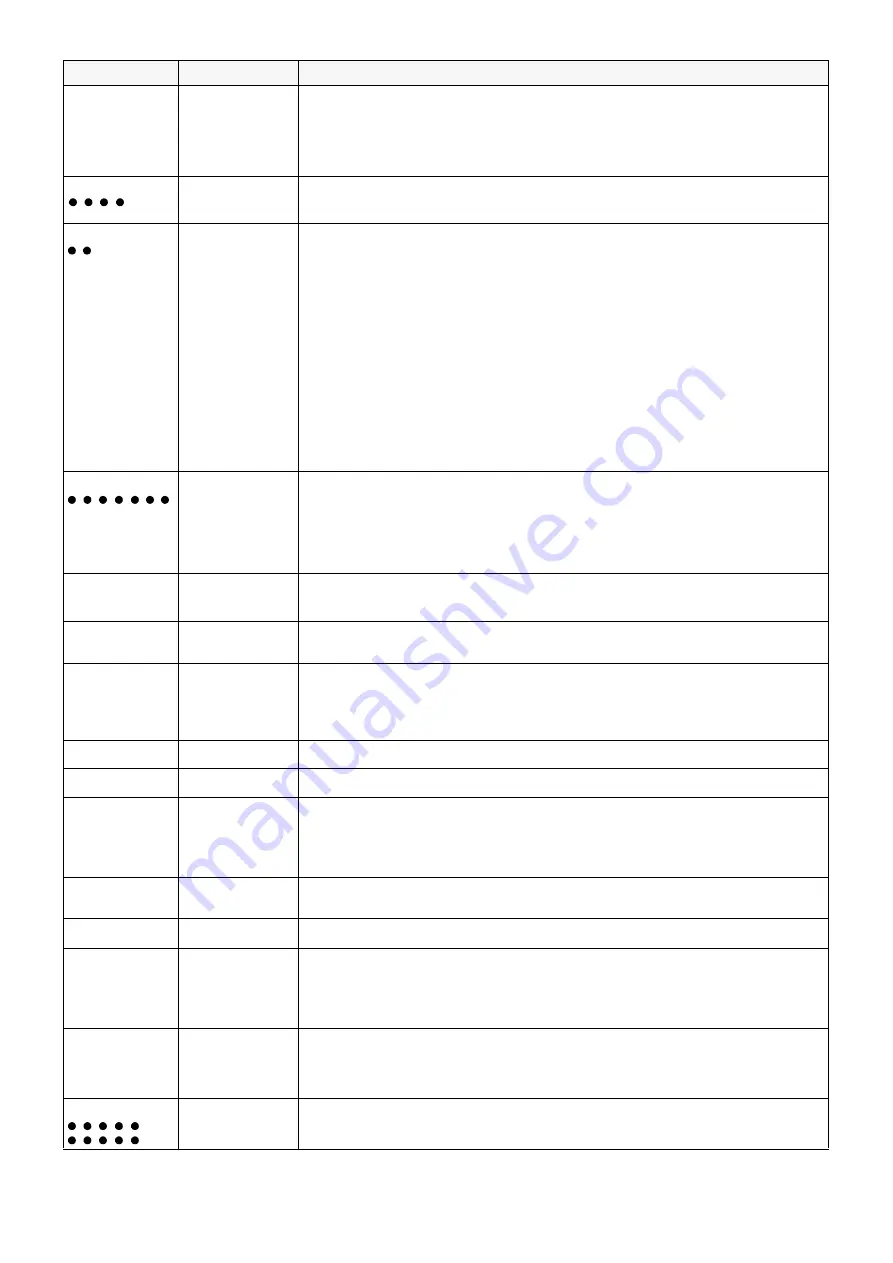

SIGNAL

FAULT

PROBABLE CAUSE

SUGGESTED REMEDY

No blink

The burner does not

start

77 - No electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . Close all switches - Check fuses

78 - Linmit control device TL is open . . . . . . . . . . . . . . . . . . . . . Adjust or replace

79 - Safety control device TS is open. . . . . . . . . . . . . . . . . . . . . Adjust or replace

80 - Control box lock-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reset control box (no sooner than 10 s after the lock-out)

81 - Pump is jammed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

82 - Erroneous electrical connections . . . . . . . . . . . . . . . . . . . . Check connections

83 - Defective control box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

84 - Defective electrical motor . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

4 led

The burner starts

and then goes into lock-

out

85 - Photocell short-circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace photocel

86 - Light is entering or flame is simulated. . . . . . . . . . . . . . . . . Eliminate light or replace control box

2 led

After pre-purge and the

safety time,

the burner goes to lock-

out

and the flame does not

appear

87 - No fuel in tank; water on tank bottom . . . . . . . . . . . . . . . . . Top up fuel level or suck up water

88 - Inappropriate head and air damper adjustments. . . . . . . . . Adjust

89 - Light oil solenoid valves fail to open (1st stage or safety) . . Check connections; replace coil

90 - 1st stage nozzle clogged, dirty, or deformed. . . . . . . . . . . . Replace

91 - Dirty or poorly adjusted firing electrodes. . . . . . . . . . . . . . . Adjust or clean

92 - Grounded electrode due to broken insulation . . . . . . . . . . . Replace

93 - High voltage cable defective or grounded . . . . . . . . . . . . . . Replace

94 - High voltage cable deformed by high temperature . . . . . . . Replace and protect

95 - Ignition transformer defective . . . . . . . . . . . . . . . . . . . . . . . Replace

96 - Erroneous valves or transformer electrical connections . . . Check

97 - Control box defective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

98 - Pump unprimed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Prime pump and see “Pump unprimes”

99 - Pump/motor coupling broken . . . . . . . . . . . . . . . . . . . . . . . Replace

100- Pump suction line connected to return line . . . . . . . . . . . . . Correct connection

101- Valves up-line from pump closed . . . . . . . . . . . . . . . . . . . . Open

102- Filters dirty: line - pump - nozzle . . . . . . . . . . . . . . . . . . . . . Clean

103- Defective photocell or control box . . . . . . . . . . . . . . . . . . . . Replace photocell or control box

104- Dirty photocell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean

105- 1st stage operation of cylinder is faulty . . . . . . . . . . . . . . . . Change the cylinder

106- Motor protection tripped . . . . . . . . . . . . . . . . . . . . . . . . . . . Reset thermal cut-out

107- Defective motor command control device . . . . . . . . . . . . . . Replace

108- Missing phase thermal cut-out trips . . . . . . . . . . . . . . . . . . . . . . . Reset thermal cut-out when third phaseis re-connected

109- Incorrect motor rotation direction . . . . . . . . . . . . . . . . . . . . Change motor electrical connections

7 led

110- Poorly adjusted head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjust

111 - Poorly adjusted or dirty firing electrodes . . . . . . . . . . . . . . . Adjust

112- Poorly adjusted fan air gate: too much air (1st stage). . . . . Adjust

113- 1st nozzle is too big (pulsation). . . . . . . . . . . . . . . . . . . . . . Reduce 1st nozzle delivery

114- 1st nozzle is too small (flame detachment) . . . . . . . . . . . . . Increase 1st nozzle delivery

115- 1st nozzle dirty, or deformed . . . . . . . . . . . . . . . . . . . . . . . . Replace

116- Inappropriate pump pressure . . . . . . . . . . . . . . . . . . . . . . . Adjust to between 10 and 14 bar

117- 1st stage nozzle unsuited to burner or boiler . . . . . . . . . . . See Nozzle Table, page 12; reduce 1st stage

118- Defective 1st stage nozzle . . . . . . . . . . . . . . . . . . . . . . . . . Replace

The burner does not

pass to 2nd stage

119- Control device TR does not close . . . . . . . . . . . . . . . . . . . . Adjust or replace

120- Defective control box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

121- 2nd stage sol. valve coil defective. . . . . . . . . . . . . . . . . . . . Replace

122- Piston jammed in valve unit . . . . . . . . . . . . . . . . . . . . . . . . Replace entire unit

Fuel passes to 2nd

stage

but air remains in 1st

123- Low pump pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Increase

124- 2nd stage operation of cylinder is faulty . . . . . . . . . . . . . . . Change cylinder

Burner stops at transi-

tion

between 1st and 2nd

stage.

Burner repeats starting

cycle

125- Nozzle dirty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Renew nozzle

126- Photocell dirty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean

127- Excess air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reduce

Uneven fuel supply

128- Check if cause is in pump . . . . . . . . . . . . . . . . . . . . . . . . . . Feed burner from tank

or fuel supply system

located near burner

Internally rusted pump

129- Water in tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suck water from tank bottom with separate pump

Noisy pump, unstable

pressure

130- Air has entered the suction line . . . . . . . . . . . . . . . . . . . . . Tighten connectors

- Depression value too high (higher than 35 cm Hg):

131- Tank/burner height difference too great. . . . . . . . . . . . . . . . Feed burner with loop circuit

132- Piping diameter too small . . . . . . . . . . . . . . . . . . . . . . . . . . Increase

133- Suction filters clogged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean

134- Suction valves closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Open

135- Paraffin solidified due to low temperature . . . . . . . . . . . . . . Add additive to light oil

Pump unprimes after

prolonged pause

136- Return pipe not immersed in fuel . . . . . . . . . . . . . . . . . . . . Bring to same height as suction pipe

137- Air enters suction piping . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten connectors

Pump leaks light oil

138- Leakage from sealing organ . . . . . . . . . . . . . . . . . . . . . . . . Replace

pump

Smoke in flame

- dark Bacharach

- yellow Bacharach

139- Not enough air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjust head and fan gate

140- Nozzle worn or dirty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

141- Nozzle filter clogged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean or replace

142- Erroneous pump pressure. . . . . . . . . . . . . . . . . . . . . . . . . . Adjust to between 10 - 14 bar

143- Flame stability spirat dirty, loose, or deformed . . . . . . . . . . Clean, tighten in place, or replace

144- Boiler room air vents insufficient . . . . . . . . . . . . . . . . . . . . . Increase

145- Too much air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjust head and fan gate

Dirty combustion head

146- Nozzle or filter dirty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replace

147- Unsuitable nozzle delivery or angle. . . . . . . . . . . . . . . . . . . See recommended nozzles

148- Loose nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten

149- Impurities on flame stability spiral . . . . . . . . . . . . . . . . . . . . Clean

150- Erroneous head adjustment or not enough air . . . . . . . . . . Adjust; open gate valve

151- Blast tube length unsuited to boiler . . . . . . . . . . . . . . . . . . . Contact boiler manufacturer

10 led

152- Connection or internal fault

Summary of Contents for 3478410

Page 2: ......

Page 43: ...43 RL 300 B MZ...

Page 44: ...44 RL 400 B MZ...

Page 45: ...45 RL 300 B MZ...

Page 46: ...46 RL 400 B MZ...

Page 47: ...47...

Page 48: ...48...

Page 49: ...49...

Page 50: ...50...

Page 53: ......

Page 54: ......

Page 55: ......