2332

7

GB

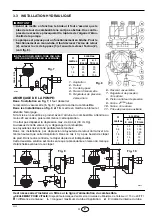

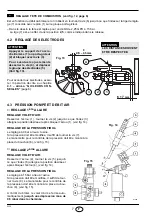

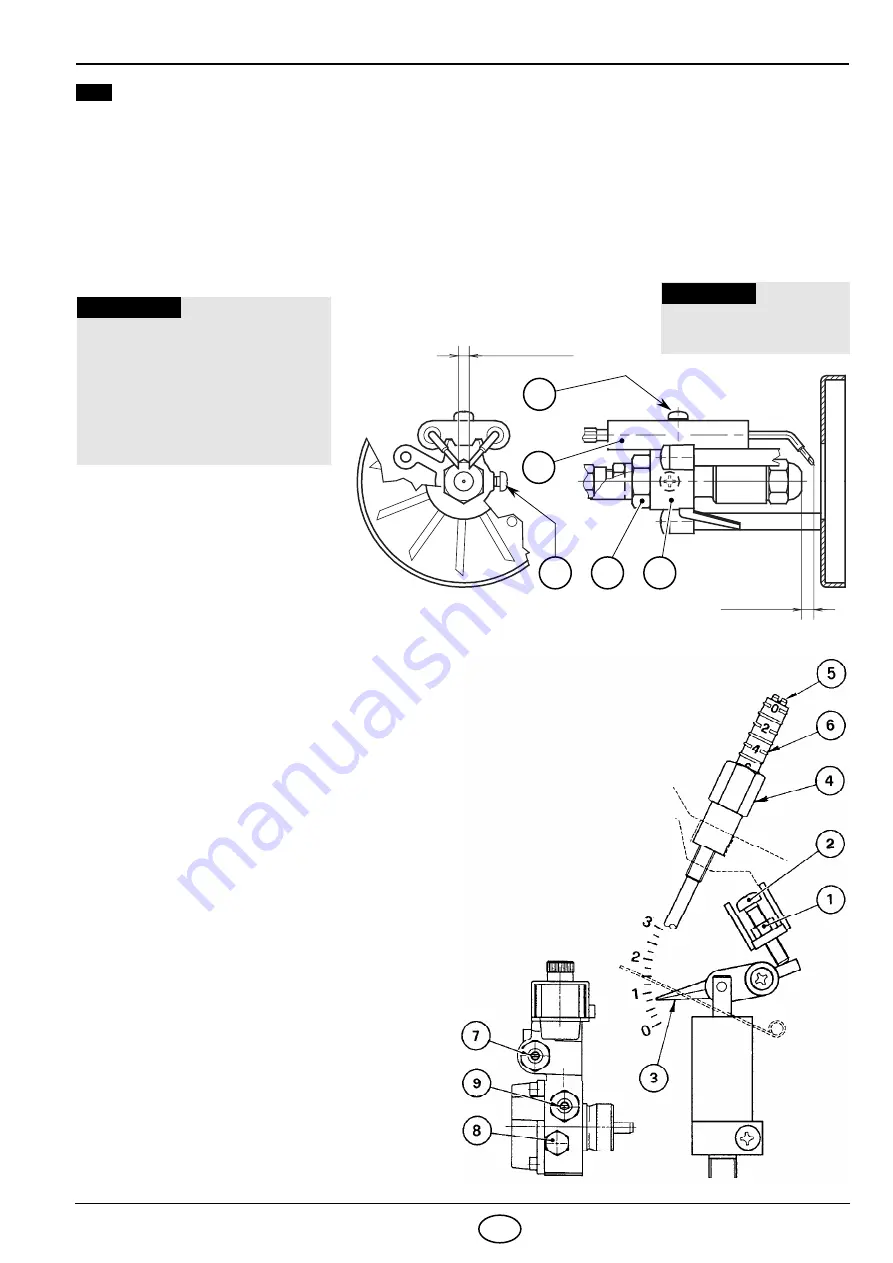

COMBUSTION HEAD SETTING (see fig. 12, page 6)

It depends on the output of the burner and is carried out by rotating clockwise or counterclockwise the set-

ting screw (6) until the set-point marked on the regulating rod (7) is level with the outside plane of the

nozzle-holder assembly (1).

– In the sketch the combustion head is set for an output of 2.25 GPH at 15 bar.

The set-point 2.5 of the regulating rod is at the same level with the outside plane of the nozzle-holder as-

sembly as shown in the schedule.

4.2

ELECTRODES ADJUSTMENT

2

Fig. 15

Fig. 14

S7064

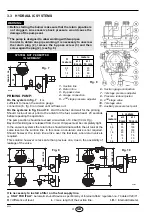

Lean the diffuser disc-holder

assembly (1) on the nozzle-

holder (2) and lock it by screw

( 3 ) . For prospective adjust-

ments loosen screw (4) and

move the electrodes assembly

(5), (see fig. 13).

ATTENTION

To have access to the electrodes

carry out operation as described in

chapter 4.1 (page 6) “RECOM-

MENDED NOZZLES”.

D5341

6 – 7

mm

4.5

– 0.5 mm

0

Fig. 13

4

5

1

2

3

MEASURES MUST BE

RESPECTED

WARNING

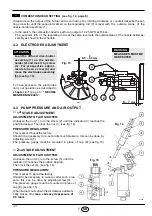

4.3

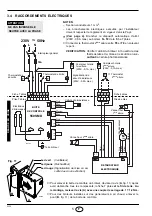

PUMP PRESSURE AND AIR OUTPUT

■

1

st

STAGE ADJUSTMENT

ADJUSTMENT OF AIR SHUTTER:

Unloosen the nut (1), turn the screw (2) until the indicator (3) reaches the

position desired. Then lock the nut (1), (see fig. 14).

PRESSURE REGULATION:

This is set at 9 bar at the factory.

Should it be necessary to re-set or alter such pressure, this can be done, by

adjusting screw (7).

The pressure gauge must be mounted in place of cap (8), (see fig. 15).

■

2

nd

STAGE ADJUSTMENT

ADJUSTMENT OF AIR SHUTTER:

Unloosen the nut (4), turn the screw (5) until the

indicator (3) reaches the position desired.

Then lock the nut (4), (see fig. 14).

PRESSURE REGULATION:

This is set at 15 bar at the factory.

Should it be necessary to re-set or alter such pres-

sure, this can be done, by adjusting screw (9).

The pressure gauge must be mounted in place of

cap (8), (see fig. 15).

When burner shuts down the air damper automati-

cally closes till a max. chimney depressure of

0,5 mbar.