2604

3

GB

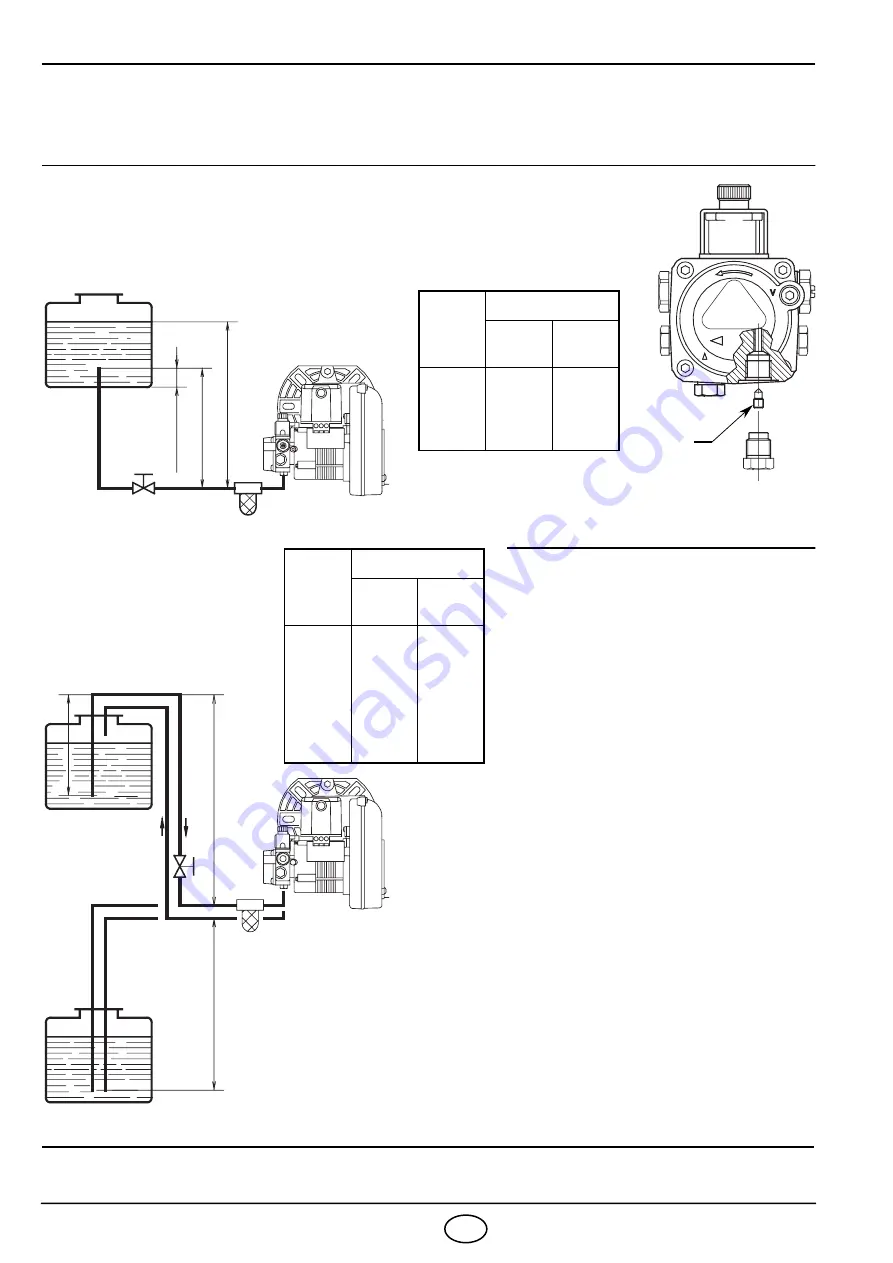

HYDRAULIC SYSTEM

Warning:

before starting the burner make sure that the return pipe-line is not clogged: any obstruc-

tion would cause the pump seals to break.

The pump vacuum should not exceed a

maximum of 0.4 bar (30 cm Hg).

Beyond this limit gas is released from

the oil.

Oil lines must be completely air-

tight.

The return line should terminate in

the oil tank at the same level as the

suction line; in this case a non-return

valve is not required.

When the return line arrives over the

fuel level, a non-return valve must be

used.

This solution however is less safe than

previous one, due to the possibility of

leakage of the valve.

PRIMING THE PUMP

Start the burner and wait for the priming.

Should lock-out occur prior to the arrival

of the fuel, await at least 20 seconds

before repeating the operation.

A filter must be installed on the suction fuel line.

H

meters

L meters

I. D.

8 mm

I.D.

10 mm

0.5

1

1.5

2

10

20

40

60

20

40

80

100

WARNING

The pump is supplied for use with a two pipe system.

For use on a one pipe system, it is necessary to remove the by-pass

screw (A),

(see figure).

A

H

meters

L meters

I. D.

8 mm

I.D.

10 mm

0

0.5

1

1.5

2

3

3.5

35

30

25

20

15

8

6

100

100

100

90

70

30

20

H

max.

4 m

H

H

max.

4 m

min.

0.1 m

D5616

D5617

D5199

H =

Difference of level.

L

= Max.

length of the

suction line.

I.D. =

Internal diameter of the

oil pipes.

PRIMING THE PUMP

Loosen the plug of the vacuum gauge (5, fig. 1,

page 1) and wait until the fuel flows out.