2347

2

GB

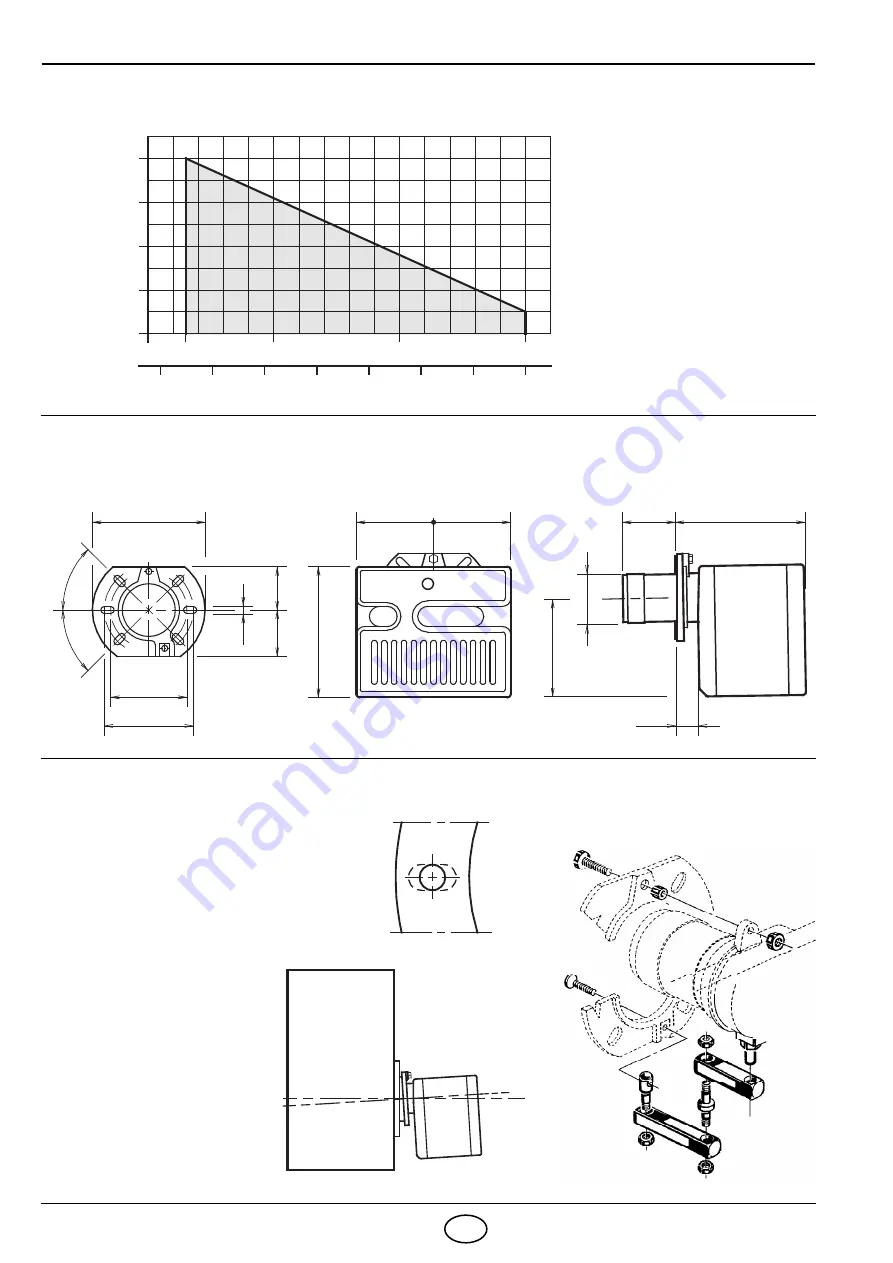

WORKING RANGE

DIMENSIONS

MOUNTING THE BURNER

0.8

0

0.4

Pressure in the comb

ustion

c

hamber – mbar

2

3

4

5

Gas oil output - kg/h

25

30

60

Thermal power - kW

D5226

35

40

45

50

55

0.2

0.6

2.3

272

107

236

130

=

37

45

°

ø

89

233

11

180

D5554

=

180

75

72

150

45

°

Flange

Burner

It is necessary that the insulating gasket

(9, fig. 1) is placed between the boiler door

and the burner flange.

This insulating gasket has six holes,

which, if necessary, can be modified as

shown on the drawing on the right.

D5242

Fig. 2

Verify that the installed

burner is lightly leaned

towards the button.

(See figure 2).

The burner is designed to

allow entry of the flexible

oil-lines on either side of

the burner.

D5572

BURNER FIXING AND

HINGE ASSEMBLY

S7384