2814

10

GB

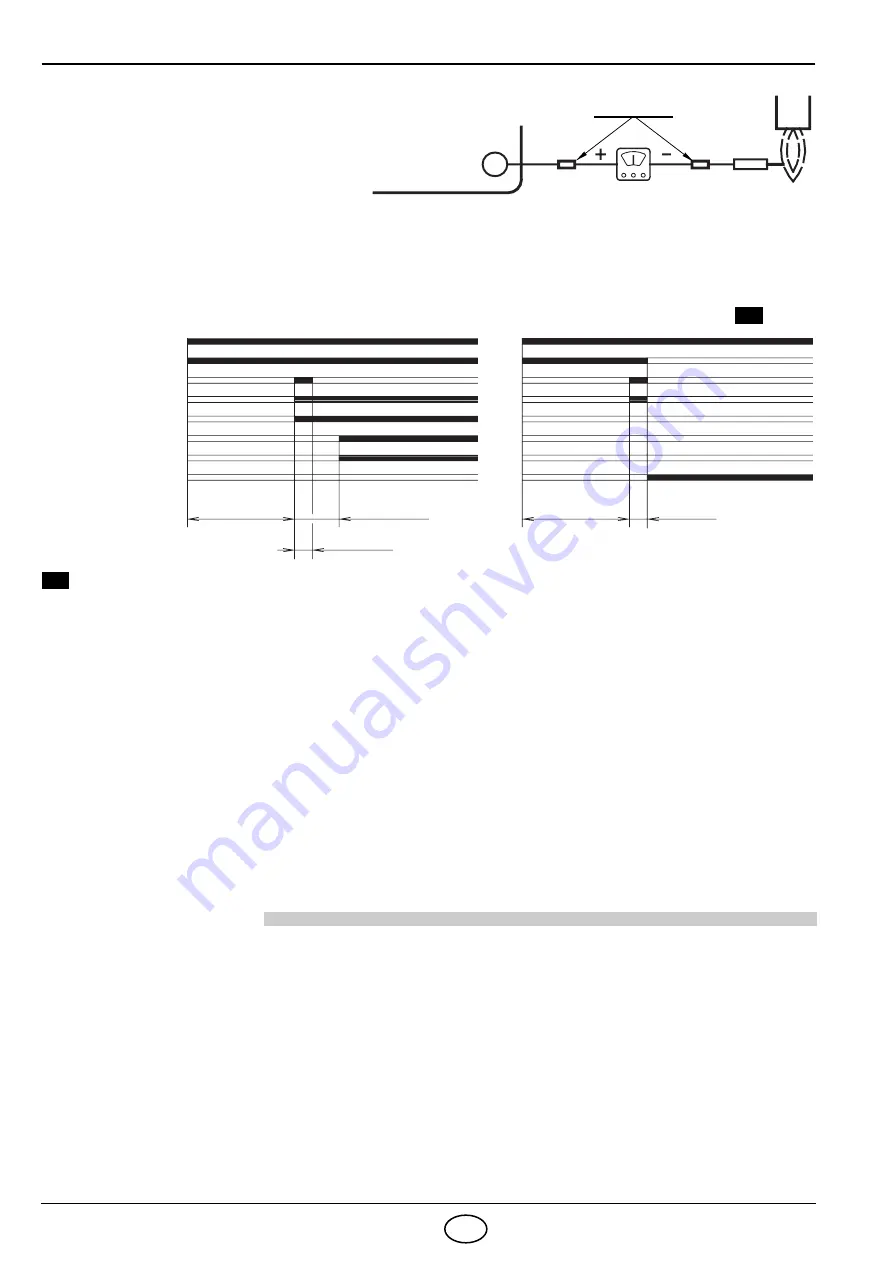

IONIZATION CURRENT

The minimum current necessary for the

control box operation is 5 µA.

The burner normally supplies a higher cur-

rent value, so that no check is needed.

Anyway, if you want to measure the ioni-

zation current, you have to open the con-

nector (CN1) (see electrical scheme page 6) fitted on the wire and insert a microammeter, (see fig. 10).

4.5

BURNER START-UP CYCLE

Lock-out is indicated by a lamp on the control box (4, fig. 1, page 1).

When the flame-failure occurs during working, shut down takes place within one second.

4.6

AIR PRESSURE SWITCH

Adjust the air pressure switch after having performed all other burner adjustments with the air pressure

switch set to the start of the scale.

With the burner operating at the required power, slowly turn knob clockwise until burner locks out.

Then turn the knob anti-clockwise by about 20% of the set point and subsequently check to see if burner

has started correctly. If the burner locks out again, turn the knob anti-clockwise a little bit more.

The burner leaves the factory with the pressure switch set at the beginning of the scale.

Attention:

As a rule, the air pressure switch must prevent the air pressure from lowering below 80 % of the adjustment

value as well as preventing the CO in the fumes from exceeding 1% (10,000 ppm).

To check this, insert a combustion analyser into the chimney, slowly close the fan suction inlet

(for example

with cardboard)

and check that the burner locks out, before the CO in the fumes exceeds 1 %.

5.

MAINTENANCE

The burner requires periodic maintenance carried out by a qualified and authorised technician in conform-

ity with legislation and local standards

.

Maintenance is essential for the reliability of the burner, avoiding the excessive consumption of fuel and

consequent pollution.

Before carrying out any cleaning or control always first switch off the electrical supply to the

burner acting on the main switch of the system.

THE BASIC CHECKS ARE:

Leave the burner working without interruption for 10 min., checking the right settings of all the components

stated in this manual. Then carry out a combustion check verifying:

●

CO

2

( %) content

●

Smoke temperature at the chimney

●

CO content (ppm).

Probe

Connector

Terminal block

of control-box

D5006

Fig. 10

Thermostat

Motor

Ignition transformer

First valve

First flame

Second valve

40s min.

3s max.

40s min.

3s max.

Lock-out, due to light failure

A

Normal

Second flame

Lock-out

3 – 8s

D5016

A