12

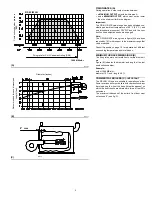

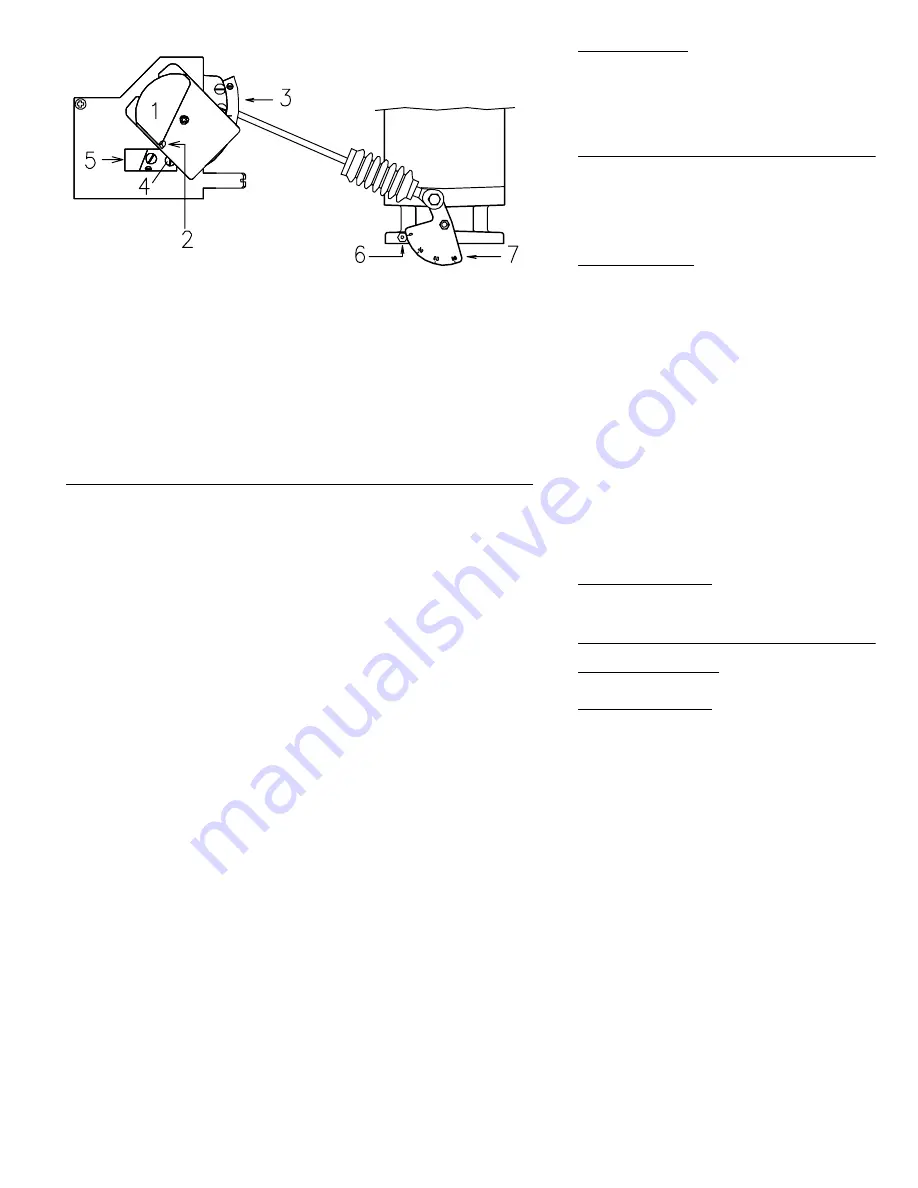

Adjusting air delivery

Progressively adjust the end profile of cam 4)(A) by turn-

ing the cam adjustment screws as they appear through

the access opening 6)(A).

- Turn the screws clockwise to increase air delivery.

- Turn the screws counter-clockwise to reduce air deliv-

ery.

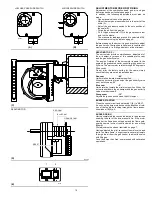

3 - MINIMUM OUTPUT

Minimum output must be selected within the firing rate

range shown on page 5.

Press switch 2)(A)p.11 “output reduction” until the servo-

motor has closed the air damper and the gas butterfly

valve to 15° (factory set adjustment).

Adjusting gas delivery

Measure the delivery of gas from the gas meter.

- If this value is to be reduced, decrease the angle of

orange cam (B) slightly by proceeding a little at a time

until the angle is changed from 15° to 13° or 11°....

- If it has to be increased press the switch “output

increase” 2)(A)p.11 (i.e. open the gas butterfly valve

by 10-15°), increase the orange cam angle (B) with

small successive movements, i.e. take it from angle

15° to 17° - 19°....

Then press the switch “output decrease” until the ser-

vomotor is taken to the minimum opening position and

measure the gas delivery.

Note

The servomotor follows the adjustment of cam only

when the cam angle is reduced. If it is necessary to

increase the cam angle, first increase the servomotor

angle with the switch “output increase”, then increase

the orange cam angle, and at the end bring the servo-

motor back to the MIN output position with the switch

”output decrease”.

Adjustment of air delivery

Progressively adjust the starting profile of cam 4)(A) by

turning the screws working throught the access hole

6)(A).

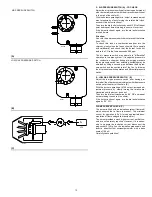

4 - INTERMEDIATE OUTPUTS

Adjustment of gas delivery

No adjustment of gas delivery is required.

Adjustment of air delivery

With the switch 1)(A) page 11 move in intermediate out-

puts and set the variable profile cam 4) by turning the

screws 5).

- If the burner operation is low-high it is sufficient to set

only minimum and maximum firing rates

- If the burner operation is modulating, all the points of

modulation should be adjusted.

When the adjustment is complete, release the servomo-

tor and manually check there is no binding of the cam.

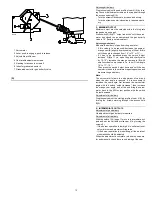

(A)

1 Servomotor

2 Lever, push to engage, push to release

3 Adjustable profile cam

4 Cam profile adjustment screws

5 Opening for access to screws 5

6 Index for graduated sector 8

7 Graduated sector for gas butterfly valve

D2267