20

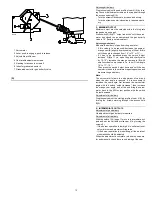

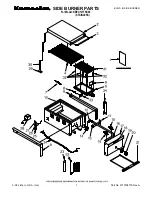

BURNER OPERATION

BURNER STARTING

• Operating closes.

Fan motor starts.

• Servomotor starts:

90° rotation to right, until contact is made on red cam.

The air damper is positioned to MAX. output.

• Pre-purge stage with air delivery at MAX. output.

• After pre-purge stage, servomotor rotates to left up to

the angle set on blu cam for MIN. output.

• The air damper and the gas butterfly are positioned to

MIN. output.

• Ignition electrode strikes a spark.

• Pilot valve opens. The pilot flame is ignited.

• After about 12s the main flame ignites and starting

cycle ends.

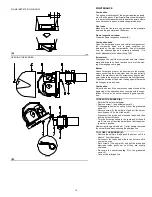

STEADY STATE OPERATION

Burner without modulating control RWF40

At the end of the starting cycle, the servomotor control

then passes to the load control for boiler pressure or

temperature.

(The flame safeguard continues, however, to check that

the flame is present and that the air pressure switch is in

the correct position.)

• If the temperature or pressure is low, the burner pro-

gressively increases its output to the MAX. value.

• If the temperature or pressure is high, the burner pro-

gressively decreases its output to the MIN. value.

And so on.

• The burner locks out when demand for heat is less

than the heat supplied by the burner at min. output.

Load control opens. The servomotor returns to the 0°

angle limited by contact with orange cam. The air

damper closes completely to reduce thermal disper-

sion to a minimum.

Every time output is changed, the servomotor automati-

cally modifies gas delivery (gas butterfly valve) and air

delivery (fan damper).

Burner with modulating control RWF40

See the handbook enclosed with the modulating control.

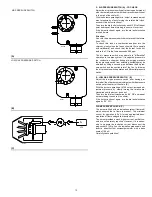

Switching times are given in seconds, in the burner star-

tup sequence.

*

Variable to air damper setting.

Legend for the times

t1

Pre-purge time with air damper open

t2

Safety time

t3

Pre-ignition time, short (ignition transformer on

terminal 16)

t4

Interval between start of t2 and release of valve

at terminal 19

t5

Interval between end of t4 and release of load

controller or valve at terminal 20

t5

Running time of air damper into OPEN position

t6

Running time of air damper into low-flame posi-

tion (MIN)

t7

Permissible after-burn time

t8

Interval until OPEN command for the air damper

is given

t9

Running time of pilot

t10

Interval between end of t4 and end start up

sequence

FIRING FAILURE

If the burner does not fire, it locks out within 2.5 seconds

from opening the pilot valve and then within 5 seconds

from opening the main valves.

BURNER FLAME GOES OUT DURING OPERATION

If the flame should accidentally go out during operation,

the burner will lock out within 1s.

LFL 1.335

Series 01

t1

t2

t3

t4

t5

30s

2s

4s

12.5s

*

t6

t7

t8

t9

t10

*

12s

4s

16s

10s

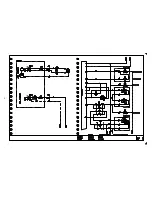

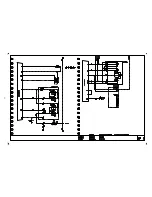

(A)

Full Modulation

D7780

Low - High

D7781

(B)

t 4

t 10

t 4

t 10