8

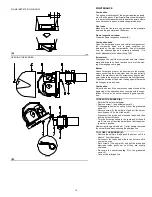

COMBUSTION HEAD ADJUSTMENT

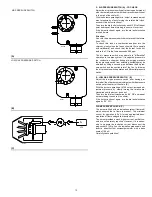

Installation operations are now at the stage where the

blast tube and sleeve are secured to the boiler as shown

in fig. (A). It is now a very simple matter to set up the

combustion head, as this depends solely on the output

developed by the burner at maximum power.

It is therefore essential to establish this value before pro-

ceeding to set up the combustion head.

There are three adjustments to make on the head:

• outside air R1;

• central air R2;

• gas deliveries R3.

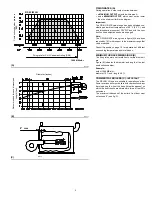

In diagram (C) find the notch to use for adjusting the air

and the gas, and then proceed as follows:

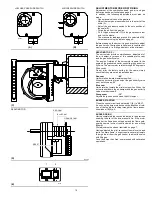

Outside air adjustment R1 (A)

Turn screw 4)(A) until the notch identified is aligned with

the front surface 5)(A) of the flange.

Gas adjustment R3 (B)

Loosen screws 1)(B) and 4)(B) and turn ring 2) until the

notch identified is aligned with index 3).

Central air adjustment R2 (B)

Turn choke 5) until the notch identified is aligned with

screw 4).

Tighten the screws 1) and 4) fully down.

Example

Burner output = 1515 MBtu/hr.

If we consult diagram (C) we find that for this output, the

adjustments are:

• outside air:

R1 = 5,3;

• central air:

R2 = 2,7;

• gas:

R3 = 0,7.

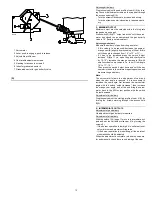

Once you have finished setting up the head, refit the

burner 4)(D) to the slide bars 3) at approximately 4” from

the sleeve 5) - burner positioned as shown in fig. (B)p. 7

- insert the flame rod cable and the ignition electrode

cable and then slide the burner up to the sleeve so that it

is positioned as shown in fig. (D).

Refit screws 2) on slide bars 3).

Secure the burner to the sleeve by tightening screw 1)

and then refit the split pin into one of two slide bars 3).

Reconnect the swivel connector 8) to the graduated sec-

tor 7).

Connect gas train and pilot train as shown in fig. (A)

page 9.

Important

When fitting the burner on the two slide bars, it is advis-

able to gently draw out the high tension cable and flame

detection probe cable until they are slightly stretched.

(A)

(C)

(B)

Notches (Air = Gas)

Burner max output

(D)

D2790

D2789

D1083