Family Aqua Condens 3.5 BIS

14

ENGLISH

15

C.T.R. FUNCTION PARAMETER 42

The C.T.R. function acts, when the delivery temperature is set

between 55°C and 65°C, by increasing the delivery T° by 5° C if

after 20 minutes of closing of the TA the T° set on the TA has not yet

been reached, and continues to increase the delivery T° up until the

closing of the TA or until the MAX HEATING SET POINT is reached.

Therefore you should consider leaving the function on. Setting

PARAMETER 42 = 1 ON or cancelling it 42 = 0 OFF.

4.6

Display and fault codes

Faults

When there is an operation fault, the display shows a flashing code

and the RESET and icons (simultaneously or otherwise). For a

description of the faults, refer to the table in the following page.

Resetting the faults

Wait about 10 seconds before resetting normal operating conditions,

Then proceed as follows:

1. Display only of the icon

The appearance of the icon indicates that an operation fault has

been diagnosed and the boiler will attempt to resolve it autonomously

(temporary stop).

If the boiler does not resume normal operation, there are two possible

display cases.

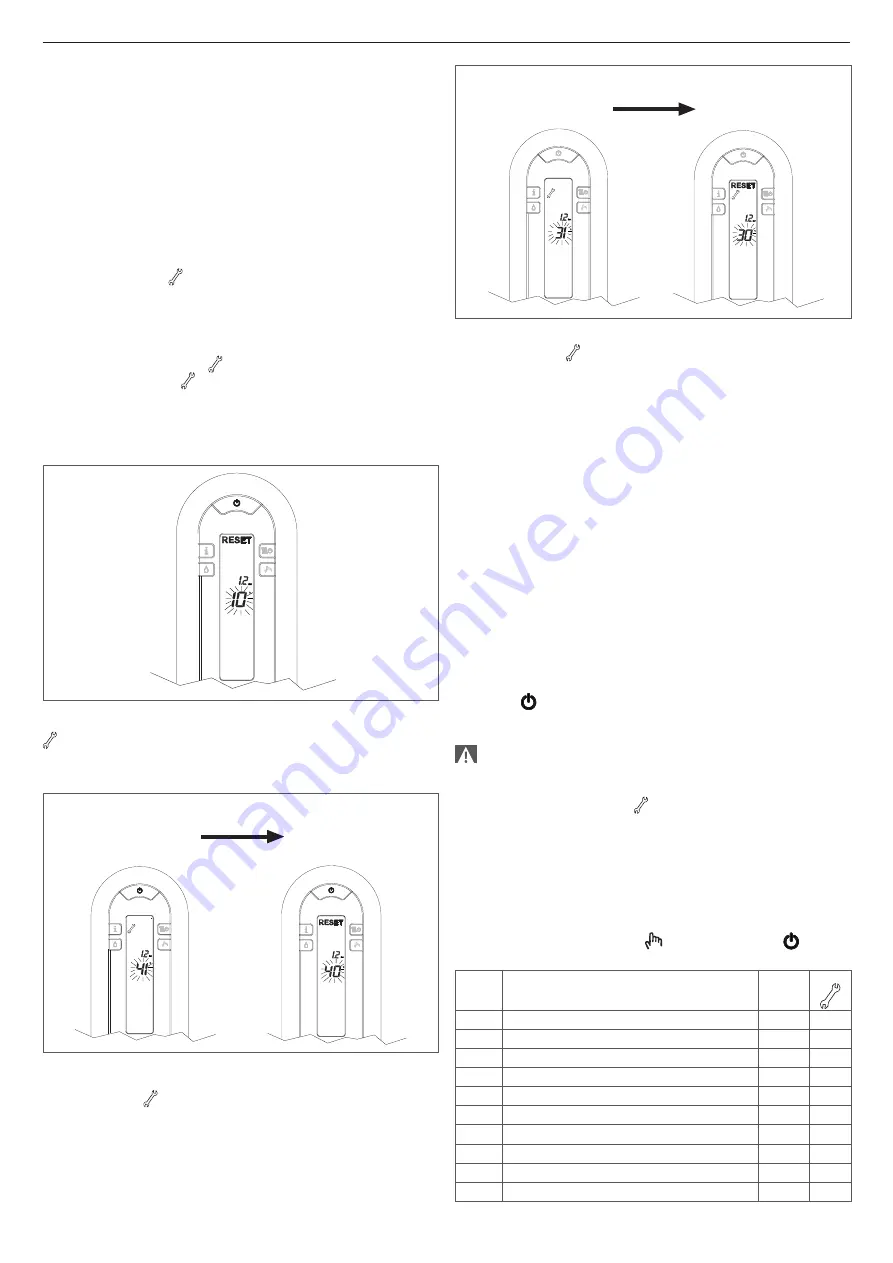

Case A

disappears, and the RESET icon appears along with a different

alarm code.

In this case, proceed as described in point 2.

CASE A

temporary

fault

definitive

fault

Case B

the RESET icon will appear along with a different alarm code,

together with the .

In this case, proceed as described in point 3.

CASE B

temporary

fault

definitive

fault

Case C

Together with the , alarm code 91 will appear (see description

below).

The intervention of the Technical Assistance Centre is required.

The boiler is equipped with an auto-diagnostic system which, based

on the total number of hours in certain operating conditions, can

signal the need to clean the primary exchanger (alarm code 91).

Once the cleaning operation has been completed, reset to zero the

total hour meter with special kit supplied as an accessory following

procedure indicated below:

- Switch off the power supply

- Remove the electric casing by means of the screws and fixing

hooks

- Extract the connector J13 (see wiring diagram)

- Power up the boiler and wait for alarm 13 to appear on the display

- Disconnect the power supply and reconnect connector J13

- Refit the electric casing and restore the boiler's function.

NOTE:

the meter resetting procedure should be carried out after

each in-depth cleaning of the primary exchanger or if this latter is

replaced.

2. Display only of the RESET icon

Press the

key to restore operation. If the boiler performs the

firing procedure and resumes normal operation, the stoppage can be

attributed to a chance situation.

Repeated lockouts require the intervention of the Riello

Technical Assistance Centre.

3. Display of the RESET and icons

The intervention of the Riello Technical Assistance Centre is required.

Fault on DHW circuit probe - 60

The fault code is only displayed in standby.

Fault J0 (card/interface connection): check that the electrical

connections are correct. If the fault persists after the control, contact

the Riello Technical Assistance Centre.

Fault J1 (without card/remote control panel connection):

to

restore the operation, press key

again and then key

until the

normal operation is restored.

Code

Fault description

RESET

icon

Icon

10

FLAME FAILURE LOCKOUT (D)

YES

NO

11

PARASITE FLAME (T)

NO

YES

12

NEW ATTEMPT IN PROGRESS (T)

NO

NO

13

MINIMUM GAS INPUT PRESSURE (T)

NO

YES

14

MINIMUM GAS INPUT PRESSURE (D)

YES

NO

20

LIMIT THERMOSTAT (D)

YES

NO

21

FLUE GAS PROBE SHORT CIRCUIT (D)

YES

YES

24

DELIVERY PROBE LIMIT TEMPERATURE (D)

YES

NO

25

DELIVERY PROBE LIMIT TEMPERATURE (T)

NO

YES

26

RETURN PROBE LIMIT TEMPERATURE (D)

YES

NO