10

b

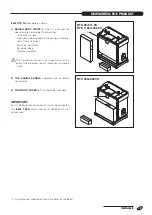

See the instruction manual provided with the burner for further information on burner installation, electrical con-

nections, burner adjustments.

If a two stage burner is installed, 1st stage heat input must not be less than 70% of total heat input.

A

ø

L

IMPORTANT

If you are installing a new boiler but re-using an old bur-

ner, always perform the following checks.

- Make sure that the performance of the old burner is

adequate for the requirements of the boiler.

- Make sure that the length and diameter of the burner’s

blast tube are as specified in the following table.

b

When you finish installing the burner in the boiler,

fill the gap between the burner’s blast tube and

the refractory material in the door with the ceramic

insulation (A) supplied with the boiler.

a

Do not re-use old burners if their blast tube lengths are below those specified in the table.

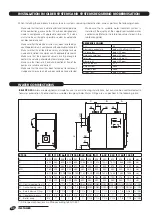

RTS 3S

90

115

166

217

255

349

448

511

639

850

1160

1450

L min

128

128

128

128

155

155

195

195

200

200

205

205

mm

Diameter of door hole

140

140

162

162

180

180

205

205

205

230

230

270

Ø mm

Thickness of door

93

93

93

93

103

103

118

118

119

119

119

119

mm

L < S

S

L

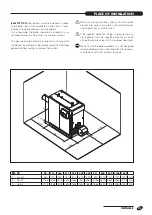

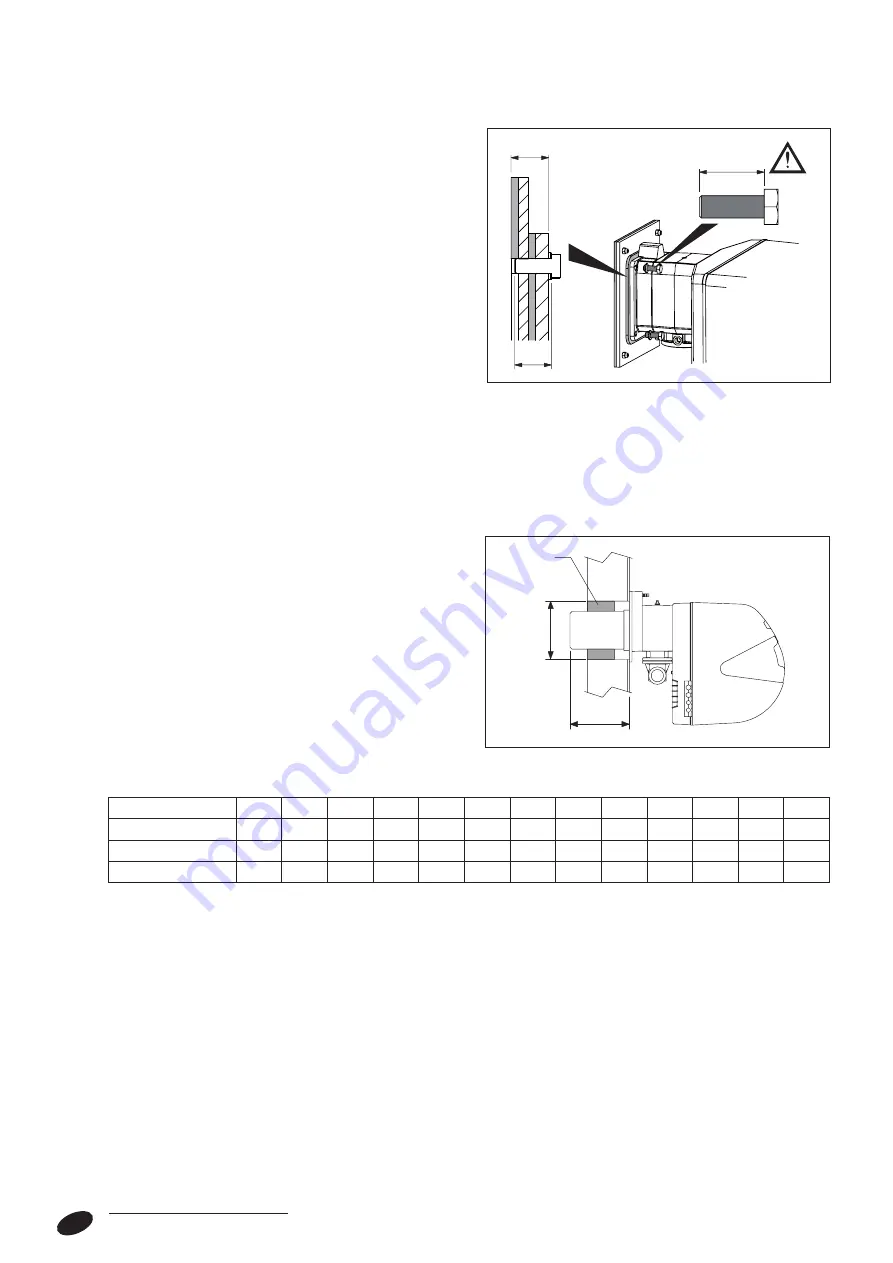

IMPORTANT NOTES FOR BURNER

INSTALLATION

Before fixing the burner to the boiler, make sure that:

- The door opens the right way (see the relevant sec-

tions for details on how to reverse the door).

- The length (L) of the burner fixing bolts is less than

(S), i.e. the total depth of the seal, plates and washer.

Longer bolts can cause the door to warp, compro-

mising its ability to seal the boiler hermetically and

permitting the release of combustion fumes.

To ensure correct burner installation, also refer to the

burner’s own manual.

GENERAL