24

INSTALLER

D

3

√

5 D

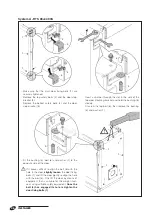

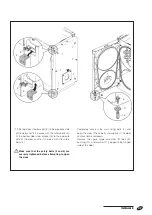

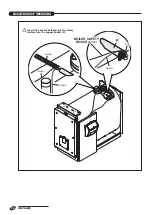

An anti-condensate pump operates during periods of

no heat request to avoid damage until the boiler returns

to a stable operating temperature. While the system is

operating, this pump must guarantee a flow rate between

20 and 30% of maximum flow, must ensure a water return

temperature no lower than the minimum permissible (see

technical data) and must also delay shutting down for at

least 3 minutes at the beginning of extended periods of

boiler shutdown (overnight or weekend shutdown etc.).

b

A sensor socket must be positioned at a distan-

ce of 3 to 5 times the diameter of the water return

pipe, upstream from the water fitting, to measure

effective water return temperature and control the

anti-condensate pump or the temperature controller

stabilisation function.

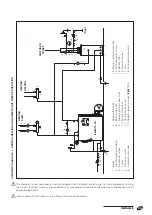

b

Any temperature controllers installed remotely from

the control panel must be compatible with the

system’s electrical connections and functioning

logic.

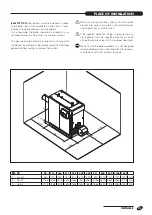

0

30

60

90

Ø

H

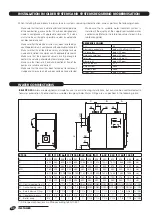

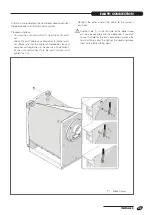

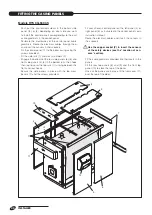

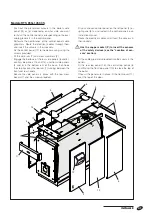

The flue gas exhaust and its connection to the stack must be made in compliance with applicable laws and standards,

using heat resistant, condensate resistant and stress resistant rigid pipe and sealed joints.

RTS 3S

90

115

166

217

255

349

448

511

639

850

1160 1450

Ø - Diameter

180

200

250

250

250

250

300

300

350

350

400

450

mm

H

870

946

1005 1005 1130 1130 1290 1290 1405 1445 1580 1695 mm

Combustion gas exhaust

COMBUSTION GAS EXHAUST

Anti-condensate pump

ANTI-CONDENSATE PUMP